Course Outline: Module 7

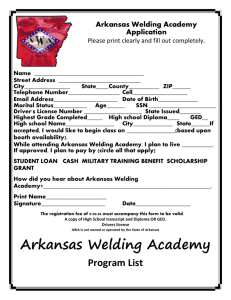

advertisement

BRX 210 – Mechanical Blue Print Reading Course Outline: Module 7 Units 22 & 23 –Symbols on Welding Drawings and Control Diagrams Introduction Module 7 introduces Industrial drawings that depend on symbols to communicate specialized information to the print reader. Welding drawings and instrumentation and control drawings (also called graphic diagrams) provide instructions to a fabricator or troubleshooter about finishing a component and how components will work together in sequence. Learning Objectives NOTE: You will be turning in the Objectives Worksheet with each Module Outline. After completing this module, you will be able to: In Unit 22: 1. Identify a welding symbol. 2. List the elements of a welding symbol. 3. Explain the meaning of a welding symbol. 4. Identify the basic weld symbols used in welding symbols. In Unit 23: 1. Describe the types of control diagrams. 2. Identify symbols used on fluid power diagrams. 3. Recognize supplementary information accompanying circuit diagrams. 4. Read a graphic diagram. 5. Interpret graphic diagrams for fluid control devices. Due This Week Assignment Format Grading Read Unit 22 on Pgs. 421 - 426 (complete questions 1-15 on pg. 427 & 428 prior to viewing the interactive lecture) Textbook 0 pts Interactive lecture Unit 22 Interactive Lecture 0 pts. Unit 22 Welding Print Reading Activity Activity 10 pts Read Unit 23 Pgs. 435 – 440 (complete questions 1-10 on pg. 441 prior to viewing the interactive lecture) Textbook 0 pts Interactive lecture Unit 23 Interactive Lecture 0 pts Unit 23 Graphic Diagram Matching Activity Activity 10 pts Unit 22 & 23 Multiple Choice Quiz Quiz 5 pts. Bonus Points Drawing 3 pts. *Use this table to fill out the course calendar. Be sure to add dates in the course calendar. ©2012 Gateway Community College 2 Learning Activities The learning activities section is a way for you to sequence your students learning. Consider this as your way of guiding them to understanding and scaffolding their learning. Be creative, use the right tool for the right objectives and whenever possible integrate knowledge checks with feedback and/or reflection. Be sure to provide an overview of each activity in the sequence and how it will help the learner achieve the learning objectives. Add learning activities as necessary. This is where you would insert lessons if you choose to use them: Lesson 1, Lesson 2, etc. See the example below. Be sure to delete from this template, any activities that you do not plan to use in this module. For example, if you will not use a “Interactive Case Study”, then delete the entire activity on Interactive Case Study. Reading Read Unit 22, Welding Prints, in Print Reading for Industry, pages 421 - 426. Welding drawings are detail drawings called inseparable-assemblies. Multiple components are welded together to make one part. To communicate welding information to a fabricator a symbol containing specific information is attached at the location for the weld. In Unit 22, you will be introduced to welding terminology and welding symbols. (You would copy/paste Reading header, and type in the assignment; copy/paste Interactive Lecture header, type assignment; copy/paste Discussion Board header, type assignment.) Interactive Lecture M7 – Unit 22, Welding Prints Welding symbols communicate important information to the welder concerning the location, size and strength of a weld. All of the instructions a welder needs to correctly fabricate a part are included in the welding symbol. The interactive lecture meets learning objectives 7.1, 7.2, 7.3, 7.4, Activity (May need a grading rubric) Assignment Name Graded Assignment Points Possible Unit 22 Welding Print Reading Activity YES 10 Unit 22 Welding Print Reading Activity – Karen – Welding Industry Print Reading exercise is on page 7 of this document. Welding prints are detail drawings that include the symbols for welding specification. Because a welding print also includes separate components to be welded together it is called an inseparable assembly and will include a parts list. ©2012 Gateway Community College 3 The Welding print reading exercise meets learning objectives 7.3, 7.4 Grading and Feedback (If applicable) Explain the parameters of the assignment. Click Here to view the rubric. You can expect this assignment to be graded within 7-10 days of your submission. Check “My Grades” for your grade and feedback. Read Unit 23, Instrumentation and Control Drawings, in Print Reading for Industry, pages 435 - 440. Graphic diagrams are the “behind the scenes” controller that tells your phone what to do when you press a button on the number pad. The system of components too small to see on the circuit boards inside the phone work similarly to when a light switch is flipped from off to on so electricity waiting in the wire can speed past the switch to a light fixture. The path taken by power, either electrical or fluid, is mapped out on an instrumentation and control diagram. (You would copy/paste Reading header, and type in the assignment; copy/paste Interactive Lecture header, type assignment; copy/paste Discussion Board header, type assignment.) Interactive Lecture M7 – Unit 23, Instrumentation and Control Drawings Instrumentation and control diagrams use symbols and lines to chart the path of electrical or fluid power. Learning the terms used in graphic diagrams and following the sequence of operations are important steps toward understanding how electrical or fluid energy can be transformed into mechanical energy. The interactive lecture meets learning objectives 7.5, 7.6, 7.7, 7.8, 7.9 Activity (May need a grading rubric) Assignment Name Graded Assignment Points Possible Unit 23 Graphic Diagram Matching Activity YES 10 Unit 23 Graphic Diagram Matching Activity – Karen –Graphic Diagram Matching exercise is on page 8 of this document. Graphic diagrams rely heavily on symbols and lines to map the path of electrical and fluid power. Reading an instrumentation and control diagram requires a specialized vocabulary and understanding of how components function. Unit 23 Graphic Diagram Matching activity meets learning objectives 7.6 Grading and Feedback (If applicable) Explain the parameters of the assignment. Click Here to view the rubric. You can expect this assignment to be graded within 7-10 days of your submission. Check “My Grades” for your grade and feedback. ©2012 Gateway Community College 4 Quiz Units 22 & 23 Work with your developer to create the test/quiz or upload a test bank. You will also need to set the other parameters of the test such as randomized questions and question blocks. Assignment Name Points Possible Due Date/Time (if tracking) Quiz Units 22 & 23 5 Date @ Time Number of Attempts Test Duration Test Availability UNLIMITED or Specific Amount (provide # of attempts) Hour, Minutes, Unlimited START: Date @ Time END: Date @ Time The quiz meets learning objectives 7.3, 7.4, 7.5, 7.7, 7.9 Tie to learning objectives, provide relevance, and be sure to provide a rubric for grading. Instructions for Submission Provide instructions for submitting here. Grading and Feedback Explain the parameters of the assignment. Provide rubric if applicable. You can expect this assignment to be graded within 7-10 days of your submission. Check “My Grades” for your grade and feedback. Quiz - Module 7 - Units 22 and 23 Exam View - Multiple Choice Questions only Unit 22 #3 Ans - A #9 Ans - C Unit 23 #1 Ans - A #2 Ans - C #4 Ans - B ©2012 Gateway Community College 5 Bonus Print reading: (Drawing on pg. 410 and 412 in Print Reading for Industry) 3 pts possible. Questions: 1. How many different component parts are listed? Answer: Seven. 2. What starts the sequence of operation? Answer: Operator actuates push-button valves (1) and (2). 3. What causes valve (5) to shift? Answer: Air pressure through push-button valves (1) and (2). ©2012 Gateway Community College 6 Unit 22 WELDING Print Reading Activity – Karen - 10 answers (Drawing on pg. 399 in Print Reading for Industry) 1. What is the total number of parts (not part numbers) required for this welded assembly? Answer: Ten. 2. According to note 3, what section of the AWS D1.1 standard should be referenced for the 100% weld penetration? Answer: 9 3. What type of weld should be used to “tack” the parts associated with item 4 in place? Answer: Fillet. 4. What process can be used after welding to blend the weld with the parts? Answer: Grinding. 5. For the process in question 5, does the welding symbol indicate flat, convex, or concave? Answer: Concave. 6. A couple of the welding symbols have a circle on the symbol elbow. What does that mean? Answer: Weld all around. 7. Are there complete dimensions on the drawing detailing all measurements for the individual parts? Answer: No. 8. Unless specified, all welds are to be class _____. Answer: IV 9. What scale are the main views on the original drawing? Answer: 1:8 (1/8) 10. How much does this part weigh after welded together? Answer: 5022 lbs ©2012 Gateway Community College 7 Unit 23 Graphic Diagram Matching Activity – Karen - 10 answers from Exam view ©2012 Gateway Community College 8