Summery of thermal flow sensor

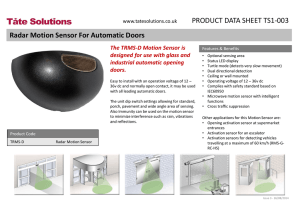

advertisement

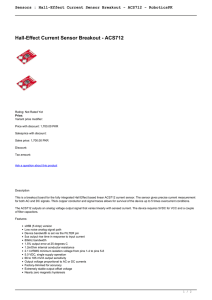

Wilfredo Gonzalez EET 3120 E260 The Flexible Sensor System Peng Liu, Rong Zhu, and Ruiyi Que explained the how important fluid mechanics is in a numerous industrial field, such as in hydroelectric dams. They introduce a new flow sensor, where the circuit is printed on a flexible thin film. Silicon-based flow sensor first developed in 1974, expensive and brittle compared to polymer and metal-based devices. The polyimide substrates advantages are it’s low cost and flexibility, but still frail and complex without the brain of the circuit the chip. This new concept of a flow sensor has all the good qualities of the pass generations. It’s flexible, cheaply produced, has a simple structure, and can be attached with ease to the objects surface, and works both integrating mechanically and electronically. How thermal flow sensors work? These sensors use heat transfer principles to come across the flow rate of a fluid. As the fluid moves through the sensor, heat is passed from the sensor to the medium. This action is dependent upon the flow rate. As flow increases, heat that is transferred to the medium also increases. The temperature of the medium can give the flow rate, and determined the amount of voltage compensation needed to maintain a constant temperature differential. The hot-film or hot-wire sensor can be operated three different modes: Constant voltage, constant current, and constant temperature. The best mode according to this article is constant temperature. While both the constant voltage and current has low sensitivity issues, as well as, the constant current had a low response. While the constant temperature the response is quicker and has a higher sensitivity.