Safe work procedure

advertisement

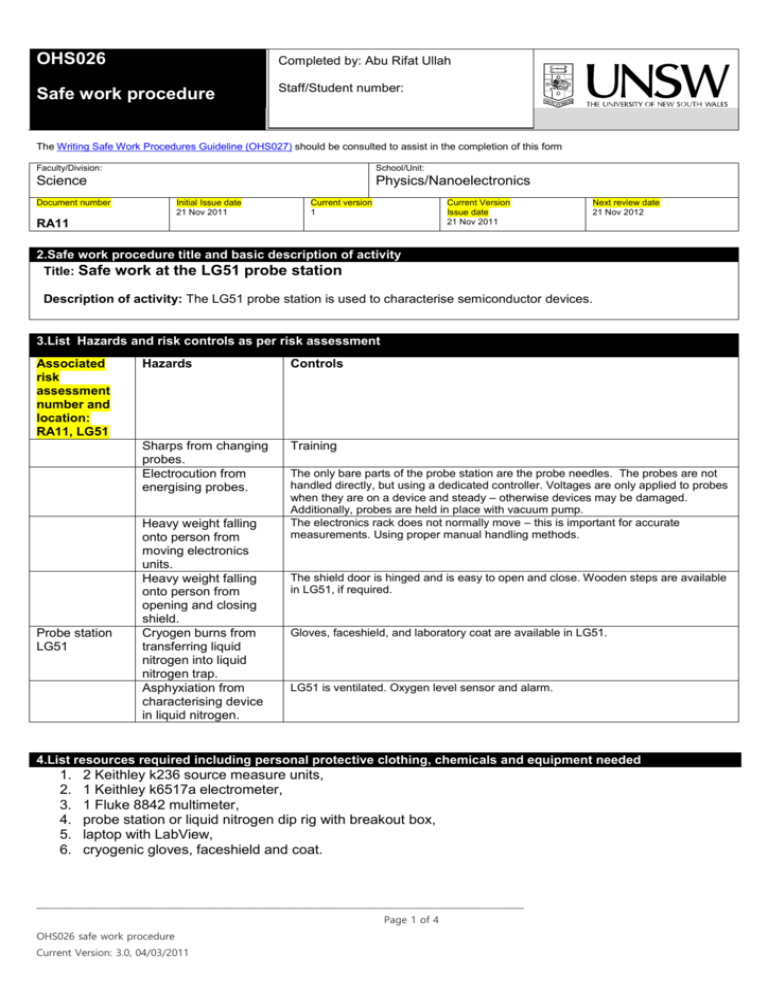

OHS026 Completed by: Abu Rifat Ullah Safe work procedure Staff/Student number: The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form Faculty/Division: School/Unit: Science Physics/Nanoelectronics Document number Initial Issue date 21 Nov 2011 Current version 1 Current Version Issue date 21 Nov 2011 RA11 Next review date 21 Nov 2012 2.Safe work procedure title and basic description of activity Title: Safe work at the LG51 probe station Description of activity: The LG51 probe station is used to characterise semiconductor devices. 3.List Hazards and risk controls as per risk assessment Associated risk assessment number and location: RA11, LG51 Probe station LG51 Hazards Controls Sharps from changing probes. Electrocution from energising probes. Training Heavy weight falling onto person from moving electronics units. Heavy weight falling onto person from opening and closing shield. Cryogen burns from transferring liquid nitrogen into liquid nitrogen trap. Asphyxiation from characterising device in liquid nitrogen. The only bare parts of the probe station are the probe needles. The probes are not handled directly, but using a dedicated controller. Voltages are only applied to probes when they are on a device and steady – otherwise devices may be damaged. Additionally, probes are held in place with vacuum pump. The electronics rack does not normally move – this is important for accurate measurements. Using proper manual handling methods. The shield door is hinged and is easy to open and close. Wooden steps are available in LG51, if required. Gloves, faceshield, and laboratory coat are available in LG51. LG51 is ventilated. Oxygen level sensor and alarm. 4.List resources required including personal protective clothing, chemicals and equipment needed 1. 2. 3. 4. 5. 6. 2 Keithley k236 source measure units, 1 Keithley k6517a electrometer, 1 Fluke 8842 multimeter, probe station or liquid nitrogen dip rig with breakout box, laptop with LabView, cryogenic gloves, faceshield and coat. _______________________________________________________________________________________________________________ Page 1 of 4 OHS026 safe work procedure Current Version: 3.0, 04/03/2011 5.List step by step instructions or order for undertaking the task Using probe station to contact to device: 1. Place device on measurement stage. 2. Ensure k236 are in standby mode. 3. Ensure electrometer has zerocheck enabled. 4. Ensure vacuum pump is running. 5. Ensure device is held in place with vacuum - use switch on right of station to switch vacuum on and off to measurement stage. 6. Move probes and contact to device – use switch on base of probe units to switch vacuum on and off to these units. 7. Use electrometer and SMUs to manually probe device. 8. Use LabView routines to characterise device. Using liquid nitrogen bath to contact to device: 1. Ensure there is sufficient liquid nitrogen in the trap. 2. Ensure retort stands are in place to support dip rig. 3. Ensure breakout box is grounded. 4. Place device (packaged onto charntec) onto liquid nitrogen dip rig. 5. Lower dip rig into liquid nitrogen slowly. 6. When in place, use retort stands to fasten rig. 7. Ensure k236 are in standby mode. 8. Ensure electrometer has zerocheck enabled. 9. Remove grounding plugs on breakout box and connect to device using coaxial cables. 10. Use electrometer and SMUs to manually probe device. 11. Use LabView routines to characterise device. 6.List emergency shutdown procedures None: 7.List Emergency procedures for how to deal with fires, spills or exposure to hazardous substances In case of electrical fire: Hit red emergency power shutdown button near entrance door. (note this is only to be used in an emergency as this power shutdown may damage equipment) In case of cryogen spill: Ask people to leave room. Shut off cryogen flow. Splashes: If a person is splashed with cryogen, immediately shut off cryogen flow. Remove affected clothing if not stuck to skin, flush cold or mild warm water from safety shower/eyewash if available or tap if outside for 10 mins. Seek medical attention while flushing, either 1st aid (Ph No. on box), UNSW health centre 55425, or 5666 if ambulance required. Do not smoke or drink alcohol. Stay with affected person till help arrives. 8.List Clean up and waste disposal requirements None. 9.List legislation used in the development of this SWP NSW OHS Act 2000 NSW OHS Regulation 2001 AS 1894 Code of Practice for the safe handling of cryogenic fluids. AS 2243.2 Safety in Laboratories:Chemical Aspects 10a.List competency required – qualifications, certificates, licensing, training - e.g. course or instruction: UNSW/Physics Liquid Nitrogen Training. _______________________________________________________________________________________________________________ Page 2 of 4 OHS026 safe work procedure Current Version: 3.0, 04/03/2011 UNSW Laboratory Safety Awareness training. Hands-on training in cryogens transfer and the use of low temperature equipment by an authorized user. 10b. List competency of Assessor Senior Experimentalist and cryogen user. 11.Supervisory approval, And review Supervisor: A/Prof Adam Micolich Responsibility for SWP review: Signature: Date of review: 12.SWP Sign off sheet SWP name and version: Probe Station SWP _______________________________________________________________________________________________________________ Page 3 of 4 OHS026 safe work procedure Current Version: 3.0, 04/03/2011 In signing this section the assessor/ authorisor agrees that the following persons are competent in following this SWP Name Signature Date Competent Name of Assessor/Authoriser _______________________________________________________________________________________________________________ Page 4 of 4 OHS026 safe work procedure Current Version: 3.0, 04/03/2011 Assessor/Authoriser signature