Energy-Efficient Heating, Ventilating and Air Conditioning

advertisement

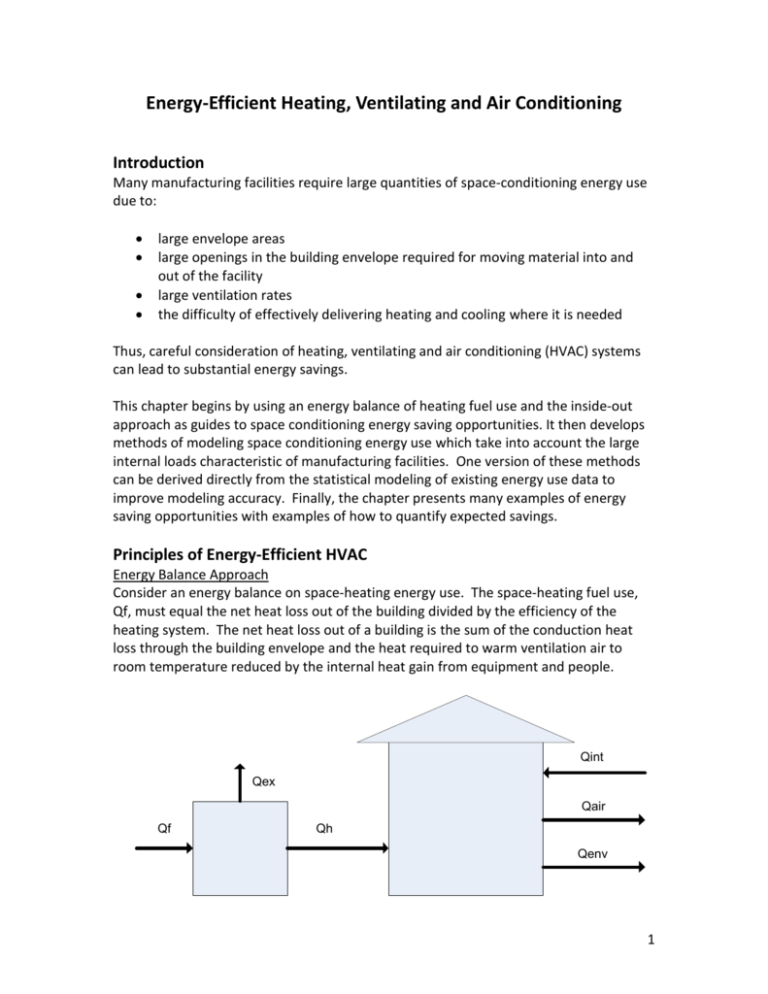

Energy-Efficient Heating, Ventilating and Air Conditioning Introduction Many manufacturing facilities require large quantities of space-conditioning energy use due to: large envelope areas large openings in the building envelope required for moving material into and out of the facility large ventilation rates the difficulty of effectively delivering heating and cooling where it is needed Thus, careful consideration of heating, ventilating and air conditioning (HVAC) systems can lead to substantial energy savings. This chapter begins by using an energy balance of heating fuel use and the inside-out approach as guides to space conditioning energy saving opportunities. It then develops methods of modeling space conditioning energy use which take into account the large internal loads characteristic of manufacturing facilities. One version of these methods can be derived directly from the statistical modeling of existing energy use data to improve modeling accuracy. Finally, the chapter presents many examples of energy saving opportunities with examples of how to quantify expected savings. Principles of Energy-Efficient HVAC Energy Balance Approach Consider an energy balance on space-heating energy use. The space-heating fuel use, Qf, must equal the net heat loss out of the building divided by the efficiency of the heating system. The net heat loss out of a building is the sum of the conduction heat loss through the building envelope and the heat required to warm ventilation air to room temperature reduced by the internal heat gain from equipment and people. Qint Qex Qair Qf Qh Qenv 1 Qf = [ Qenv + Qair – Qint ] / Eff,h Qf = [ A/R (Tia – Toa) + V pcp (Tia – Toa) – Qint ] / Eff,h Qf = [ (A/R + V pcp) (Tia – Toa) – Qint ] / Eff,h where A is the area of the envelope, R is the thermal resistance of the envelope, V is the air flow rate into/from a facility, pcp is the product of air density and specific heat, Tia is the inside air temperature, Toa is the outside air temperature, Qint is internal heat gain and Eff,h is the efficiency of the heating equipment. Following this energy balance, the opportunities for reducing heating energy use in existing facilities are: Increasing R Decreasing V Decreasing Tia Increasing utilization of Qint Increasing Eff,h The first option, increasing the thermal resistance by adding insulation is attractive because insulation is simple, passive and long lasting. However, the incremental gain of adding insulation diminishes as more insulation is added; thus adding insulation to a well-insulated envelope has less effect than adding insulation to an under-insulated envelope. Managing ventilation and infiltration air is critical to energy efficient space conditioning; careful analysis of this option is likely to result in significant saving opportunities. Inside air temperature can be reduced during non-occupied periods using programmable thermostats. In addition, effectively delivering heating to needed areas can reduce overall inside air temperature without reducing comfort. Some ventilation patterns improve utilization of internal heat gain more than others. The efficiency of space conditioning equipment varies, and utilizing the most efficient equipment for the task reduces energy use. This chapter provides many specific opportunities for acting on these variables and reducing heating and cooling energy use. The principles of energy-efficient space cooling are similar. Opportunities for Improving The Energy-Efficiency of HVAC Systems These principles can be organized using the inside-out approach, which sequentially reduces end-use energy, distribution energy, and primary conversion energy. Combining the energy balance and inside-out approaches, common opportunities to improve the energy efficiency of HVAC systems include: Reduce end use loads o Add insulation to under-insulated walls o Add double-polycarbonate sheets over windows o Replace dark roofs with white roofs in air-conditioned facilities 2 o Seal exhaust fan openings o Close dock doors using motion sensors or garage door openers o Turn off dust collectors when not in use o Turn off unnecessary exhaust air fans during winter o Introduce make-up air near exhaust air locations o Reduce temperature set points during unoccupied periods Improve efficiency of distribution system o Reduce excess temperature stratification using high-volume fans o Install radiant heaters in high ventilation areas o Reverse direction of exhaust air fans to utilize internal heat Improve efficiency of energy conversion o Pre-heat makeup air with solar panels o Use 100% efficient makeup air units to heat make up air o Use unit heaters rather than MAUs when outdoor air not required o Control MAUs with differential pressure control o Use economizers to reduce cooling loads o Use high efficiency cooling systems o Pre-heat or pre-cool outdoor air with exhaust air Calculating Hourly Heating Energy Use Energy Balance on Heating Energy Use Heating loads in manufacturing facilities are primarily driven by heat loss through the building envelope and the requirement to heat ventilation or infiltration air. In most manufacturing facilities, heat loss through the ground and solar loads are negligible compared to heat loss through the envelope and to air. Thus, heat loss through the ground and solar loads are not considered in this analysis. Further, energy storage effects are neglected except when considering temperature set back. The steady-state rate of heat loss through the building envelope, Qenv, is: Qenv = A / R (Tia – Toa) (1) where A is the area of the envelope, R is the average thermal resistance, Tia is the inside air temperature and Toa is the outside air temperature. The steady-state rate of heat lost to ventilation or infiltration air, Qair, is: Qair = V pcp (Tia – Toa) (2) where V is the air flow rate, pcp is the product of air density and specific heat, Tia is the inside air temperature and Toa is the outside air temperature. For air at standard conditions, the product of air density and specific heat is about: 3 pcp = 0.018 Btu/F-ft3 The heating load is reduced by heat discharged by electrical equipment, process heating equipment and occupants, Qi. In manufacturing facilities, these sources of internal heat gain can be significant. The net heating load, Qh, is: Qh = [ Qenv + Qair – Qi ]+ (3) The superscript + indicates that the quantity evaluates to zero if the value within the parentheses is negative. The total rate of heat loss can characterized in terms of the heating coefficient, HC, as: HC = A / R + V pcp (5) Thus, the net heating load, Qh, is: Qh = [ HC (Tia – Toa) – Qi ]+ (6) The fuel consumed by the heating system, Qf, must take into account the efficiency of the heating system, Effh. Qf = Qh / Effh = [ HC (Tia – Toa) – Qi ]+ / Effh (7) Equation 7 calculates fuel use by explicitly considering indoor air temperature and internal heat gain. An alternative but equivalent method of calculating heating energy use employs the concept of balance temperature. The balance-temperature method is easier to interpret graphically and can be used in conjunction with statistical data analysis. The balance temperature is the outside air temperature at which no heating is required. Based on this definition, balance temperature, Tb, can be calculated as: Qh = [ HC (Tia – Toa) – Qi ]+ 0 = [ HC (Tia – Tb) – Qi ]+ Tb = Tia – Qi / HC (8) Thus, the net heating load, Qh, can be calculated as: Qh = [ HC (Tia – Toa) – Qi ]+ = HC (Tb – Toa)+ (9) And, heating fuel use, Qf, can be calculated as: 4 Qf = HC / Effh (Tb – Toa)+ (10) Example Calculate hourly fuel use for a facility with the following characteristics: Length = 250 feet, width = 200 feet, ceiling height = 35 feet Average thermal resistance of walls and ceilings = 10 ft2-F-hr/Btu Average ventilation rate = 10,000 cfm Outdoor air temperature = 30 F Indoor air temperature = 70 F Average electrical power = 100 kW Efficiency of heating system = 80% Explicit Method: A = (250 ft + 200 ft + 250 ft + 200 ft) x 35 ft + (250 ft x 200 ft) = 81,500 ft2 Qenv = A / R (Tia – Toa) = 81,500 ft2 / 10 ft2-F-hr/Btu x (70 – 30) F = 326,000 Btu/h Qair = V pcp (Tia – Toa) Qair = 10,000 cfm x 60 min/hr x 0.018 Btu/F-ft3 x (70 – 30) F = 432,000 Btu/h Qi = 100 kW x 3,413 Btu/kWh = 341,300 Btu/h Qh = [ Qenv + Qair – Qi ]+ Qh = [ 326,000 Btu/hr + 432,000 Btu/hr – 341,300 Btu/hr ]+ = 416,700 Btu/h Qf = Qh / Effh = 416,700 Btu/hr / 0.80 = 520,875 Btu/h Balance-Temperature Method: A = (250 ft + 200 ft + 250 ft + 200 ft) x 35 ft + (250 ft x 200 ft) = 81,500 ft2 A / R = 81,500 ft2 / 10 ft2-F-h/Btu = 8,150 Btu/h-F V pcp = 10,000 cfm x 60 min/hr x 0.018 Btu/F-ft3 = 10,800 Btu/h-F HC = A / R + V pcp = 8,150 Btu/h-F + 10,800 Btu/h-F = 18,950 Btu/h-F Tb = Tia – Qi / HC = 70 F – 341,300 Btu/h / 18,950 Btu/h-F = 52.0 F Qh = HC (Tb – Toa)+ = 18,950 Btu/h-F (52.0 F – 30 F) = 416,700 Btu/h Qf = Qh / Effh = 416,700 Btu/h / 0.80 = 520,875 Btu/hr Calculating Annual Fuel Use with the Degree-Day Method A useful method for calculating annual heating and cooling energy use is called the degree-day method. As before, the balance temperature, Tb, is defined as the outside air temperature when the building needs no heating. This means, whenever Toa < Tbal, the building needs heating and whenever Toa > Tbal the building needs cooling. In the past, average daily temperatures were readily available but hourly temperatures were not. Thus, it was common to use average daily temperatures to determine the heating and cooling temperature drivers. To calculate annual heating degree days 5 (HDD), sum the difference between the balance and average daily outdoor air temperatures for all days during the year when Toa < Tbal. 365 HDD (Tbal) = (Tbal – Toa)+ (11) i 1 To calculate annual cooling degree days (CDD), sum the difference between the balance and average daily outdoor air temperatures for all days during the year when Toa > Tbal. 365 CDD (Tbal) = (Toa - Tbal)+ (12) i 1 Annual heating and cooling equipment energy use are then: Qf = [HC / Effh] HDD Qe = [CC / Effc] CDD (13) (14) Thus, heating and cooling degree days provide an effective way to summarize the heating and cooling driving potentials of a given climate. For example, consider the following degree days data, calculated with different balance temperatures from TMY3 data for Dayton, Ohio and Phoenix, Arizona. At a 65 F balance temperature, a the heating load for facility in Dayton, OH would be 4.62 times greater than a similar facility in Phoenix Arizona. Similarly, the cooling load for a facility in Phoenix, Arizona would be 4.17 times greater than for a similar facility in Dayton, OH. Fraction Difference = HDDTb=65,Dayton – HDDTb=55,Phoenix / HDDTb=55,Phoenix Fraction Difference = (5,902 – 1,050) / 1,050 = 462% Fraction Difference = CDDTb=65, Phoenix – CDDTb=55, Dayton / CDDTb=55, Dayton Fraction Difference = (4,643 – 898) / 4,643 = 417% 6 Tb (F) 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 Dayton, OH HDD 1,446 1,555 1,668 1,786 1,910 2,038 2,169 2,305 2,448 2,597 2,757 2,923 3,099 3,277 3,465 3,659 3,858 4,062 4,270 4,488 4,711 4,939 5,174 5,413 5,655 5,902 6,151 6,406 6,672 6,947 7,230 7,517 7,812 8,114 8,426 8,749 9,081 9,421 9,770 10,123 10,481 CDD 5,568 5,312 5,059 4,812 4,571 4,334 4,101 3,871 3,649 3,433 3,228 3,030 2,840 2,654 2,476 2,306 2,140 1,978 1,822 1,674 1,532 1,395 1,266 1,139 1,017 898 782 672 573 484 401 323 253 190 137 95 62 38 22 10 3 Tb (F) 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 Phoenix, AZ HDD CDD 0 12,718 0 12,353 0 11,988 0 11,623 0 11,258 0 10,893 1 10,530 9 10,172 20 9,818 34 9,467 51 9,119 71 8,774 97 8,436 128 8,102 166 7,774 211 7,454 261 7,140 314 6,828 375 6,524 446 6,229 527 5,945 616 5,669 713 5,401 818 5,142 931 4,889 1,050 4,643 1,176 4,405 1,307 4,171 1,446 3,944 1,590 3,723 1,742 3,510 1,900 3,304 2,065 3,103 2,233 2,906 2,406 2,714 2,583 2,526 2,764 2,342 2,949 2,163 3,139 1,988 3,335 1,818 3,536 1,655 Annual heating and cooling degree days (F-day/year) for Dayton, Ohio and Phoenix, AZ based on TMY3 data. In many residences, the heating and cooling balance temperatures are about 65 F. Thus, it became common practice to assume the balance temperature is 65 F and calculate degree days based on this assumption. Base 65-F heating and cooling degree 7 days for a given time period are often posted on the internet and reported by weather services. However, in manufacturing facilities with a wide range of internal temperatures and widely varying amounts of internal heat gain, the assumption of 65-F balance temperature is often incorrect. The loss of accuracy from using base 65 F degree days to calculate energy use depends on the difference between the actual building balance temperature and the assumed 65 F balance temperature. For example, using HDD from Dayton, Ohio calculated with a balance temperature of 65 F when the actual building balance temperature is 55 F would overestimate annual heating energy use by 62%. Fraction Change = HDDTb=65 – HDDTb=55 / HDDTb=55 = (5,902 - 3,659) / 3,659 = 61% Thus, the use of nominal base 65 F heating and cooling degree days to calculate heating and cooling energy use is not recommended. However, the degree-day method is accurate and useful when balance temperatures are calculated and heating or cooling degree days to the appropriate balance temperature are used. Example Calculate annual fuel use using HDDs for a facility in Dayton, Ohio with the following characteristics: Length = 200 feet, width = 200 feet, ceiling height = 30 feet Average thermal resistance of walls and ceilings = 10 ft2-F-hr/Btu Average ventilation rate = 10,000 cfm Average indoor air temperature during heating season = 65 F Average internal electrical power = 75 kW Efficiency of heating system = 80% Solution: A = (200 ft + 200 ft + 200 ft + 200 ft) x 30 ft + (200 ft x 200 ft) = 64,000 ft 2 A / R = 64,000 ft2 / 10 ft2-F-hr/Btu = 6,400 Btu/hr-F V pcp = 10,000 cfm x 60 min/hr x 0.018 Btu/F-ft3 = 10,800 Btu/hr-F HC = A/R + V pcp = 6,400 Btu/hr-F + 10,800 Btu/hr-F = 17,200 Btu/hr-F Qint = 75 kW x 3,413 Btu/kWh = 255,975 Btu/hr Tb = Tsp – Qint / HC = 65 F - 255,975 Btu/hr / 17,200 Btu/hr-F = 50.1 F (from table) HDD(50) = 2,757 F-day/yr Qf = HC / Effh HDD(50) Qf = 17,200 Btu/hr-F / 0.80 x 2,757 F-day/yr x 24 hr/dy x 106 Btu/mmBtu Qf = 1,423 mmBtu/yr A graph showing monthly space-heating fuel use versus outdoor air temperature for this facility is plotted below. 8 Determining Building Parameters from Using Inverse Modeling The most common type of building energy use modeling begins with estimates of building parameters such as area, thermal resistance and ventilation rate and proceeds to calculate fuel use. This procedure is called “forward” modeling. Inverse modeling, begins with measured building fuel use and weather data and calculates building parameters such as heating coefficient, balance temperature and effective internal heat gain from the relationship between fuel use and weather data. This section describes the use of the inverse modeling approach. In the methods presented above, the facility’s heating coefficient, balance temperature and effective internal heat gain were calculated based on estimates of envelope area, thermal resistance, ventilation rate and effective internal heat gain. However, the facility’s actual heating coefficient, balance temperature and effective internal heat gain can be determined by modeling monthly fuel use as a function of monthly average temperature using a three-parameter heating, 3PH, model. This inverse method significantly improves the accuracy of the baseline energy use model. In a 3PH model, fuel use, Qf, is modeled in terms of three regression coefficients versus outdoor air temperature, Toa, as: Qf = Qfi + HS (Tcp – Toa)+ (15) The three regression coefficients determined from the regression are weather independent fuel use, Qfi, heating slope, HS, and change-point temperature, Tcp. The 9 heating slope, HS, is the quotient of the heating coefficient, HC, and heating system efficiency, Effh. HS = HC / Effh (16) Thus, the heating coefficient is: HC = HS Effh (17) The balance temperature, Tb, is the change-point temperature, Tcp. Tb = Tcp (18) The internal heat gain, Qi, can be calculated using the equation for balance temperature: Qi = HC (Tia – Tb) (19) As before, net hourly heating load can then be calculated using the explicit or balance temperature methods: Qh = [ HC (Tia – Toa) – Qi ]+ = HC (Tb – Toa)+ Similarly, annual heating fuel use can be calculated from the heating degree-days calculated with balance temperature Tb, HDD(Tb), as: Qf = [HC / Effh] HDD(Tb) = HS HDD(Tb) (20) Thus, statistical analysis of monthly fuel use can be used in place of, or as a check against, estimates of a building’s envelope area, envelop thermal resistance, ventilation rate and internal loads. Example A 3PH model of facility natural gas use versus outdoor air temperature yields the following coefficients: Heating slope = 0.500 mmBtu/day-F Change-point temperature = 55 F Independent fuel use = 0 Calculate fuel use for the facility when: Indoor air temperature = 70 F Outdoor air temperature = 30 F Efficiency of heating system = 80% Solution: 10 HC = HS Effh = 0.500 mmBtu/day-F x 0.80 x 106 Btu/mmBtu / 24 h/day = 16,677 Btu/h-F Tb = Tcp = 55 F Qh = HC (Tb – Toa)+ = 16,677 Btu/h-F (55 F – 30 F)+ = 416,677 Btu/h Qf = Qh / Effh = 416,677 Btu/hr / 0.80 = 520,833 Btu/h Or, using the explicit method: Qi = HC (Tia – Tb) = 16,677 Btu/h-F (70 F – 55 F) = 250,000 Btu/h Qh = [HC (Tia – Toa) – Qi ]+ Qh = [ 16,677 Btu/h-F (70 – 30) F – 250,000 Btu/hr ]+ = 416,677 Btu/h Qf = Qh / Effh = 416,677 Btu/hr / 0.80 = 520,833 Btu/h Heating System Equipment The principle types of heating units used in manufacturing facilities are: Make-up air units (MAUs) Indoor air heaters Air handlers Infrared heating units Characteristics of these types of heating units are discussed below. Proper selection and operation of heating system equipment can significantly reduce heating energy costs. Make-up Air Units Make-up air units, MAUs, supply outdoor air to replace air discharged through ventilation fans and from process heating equipment. Because MAUs bring large quantities of makeup air into the facility, the air is typically heated using direct-fire burners which mix the products of combustion with the supply air. Hence, the heating efficiency of direct-fire MAUs is 100%. It is easy to tell if a MAU uses direct fire burners by noting whether the unit has an exhaust stack. If not, then the products of combustion are added to the ventilation air and the thermal efficiency of the unit is 100%. If it does, then the hot products of combustion are exhausted through the stack and the thermal efficiency of the unit is typically about 80%. In the MAU shown below, outside air is drawn into the unit on the right, passes through filters, is heated by a direct fire natural gas burner, and is blown into the facility on the right by a centrifugal fan. 11 Make-up air unit. Source www.greenheck.com. The burner firing rate of make-up air units is controlled by a thermostat located at the exit of the MAU or on the plant floor. When the thermostat is located at the exit of the MAU, the control algorithm is typically to enable the burner whenever the outside air temperature drops below some outside air set-point temperature, and then varying burner firing rate to heat the air to the discharge air set-point temperature. This type of control makes it difficult to maintain space temperature within a narrow range. Locating the thermostat in the conditioned space, and controlling burner firing rate to add enough heat to maintain the space temperature within the set-point dead band temperature improves control. Some makeup air units have variable speed fans or outdoor air dampers that are controlled to maintain a slight positive pressure in the facility. This type of differential pressure control effectively eliminates infiltration through the facility envelope and ensures that all outside air is heated using 100%-efficient direct-fire burners. Indoor-Air Heaters Indoor-air heaters blow indoor air across heating coils, much like residential furnaces. There are many types of indoor-air heaters. Ceiling-mounted gas-fired indoor-air heaters are often called ‘unit heaters’. Ceiling mounted units with steam or hot-water coils are often called ‘fan-coil units’. Floor-mounted heaters that collect air from the bottom of the unit and discharge heated air from the top are often called ‘air rotation units’. 12 Gas-fired unit heater. Source www.lenox.com. Because indoor-air heaters heat indoor air, the products of combustion in gas-fired units must be exhausted and the thermal efficiency of the units is typically 80%. In steam or hot-water heated fan-coil units, the thermal efficiency is the efficiency of the steam or hot water system. Although the thermal efficiency of indoor-air heaters is 80% compared to 100% for makeup air units, heating with indoor-air heaters is more efficient than heating with makeup air units when outside air is not required because much of the heat delivered by makeup air units is simply to raise the temperature of the outside air to room temperature. Air Handlers Air handlers mix indoor and outdoor air supply the mixed air to the facility. Air handlers come in many configurations. The unit shown below on the left uses a direct-fire burner to add heat to the outdoor air, then supplies a mixture of return and outside air to the facility. The roof-top air-handler unit on the right mixes indoor and outdoor air then draws the mixed air through heating and cooling coils before delivering it to the facility. Direct-fire air handler and rooftop air handler units. Source www.greenheck.com and www.carrier.com. The thermal efficiency of air-handlers depends on the type. The thermal efficiency of electric and direct-fired units is 100%. The thermal efficiency of most indirect-fired units is 80%. In units that utilize steam or hot-water heating coils, the thermal efficiency is the efficiency of the steam or hot water system. 13 In many units, the fraction of supply air made up by outdoor air can be varied. In cooling situations, varying the fraction of outdoor air to reduce cooling coil energy use is called economizer control. In heating situations, the fraction of outdoor air should be minimized to provide just enough outside air to meet ventilation requirements. Infrared Heaters Infrared heaters provide heat primarily by radiating infrared radiation directly from the unit heater to people and the solid objects on the floor. Because infrared heating does not rely on heated air as a heat transfer medium, it is especially effective in areas with high ventilation or infiltration loads, such as near dock doors, and in facilities with high ceilings where air-heating devices would have to heat large volumes of air. Gas-fired unit heaters direct hot combustion gasses through long dark tubes topped with reflectors to direct radiant energy to the floor. Gas-fired unit heaters have exhaust stacks and are about 80% efficient. Electric radiant heaters are 100% efficient; however, in most cases the reduced cost of natural gas compared to electricity makes up for the difference in efficiency and natural gas fired units are more economical to operate. Gas-fired u-tube infrared heating unit. Because gas-fired radiant heaters deliver heat to people at floor level so effectively, the air temperature near the ceiling is frequently less than it would be for air-heating units. Thus, the average air temperature in the facility is reduced. The reduced average air temperature lowers heat loss through the envelope and to ventilation air and reduces overall heating energy use. Thus, the use of infrared heaters is an example of how delivering heat effectively can reduce overall heating energy use. Add Insulation to Under-Insulated Envelope Components The thermal resistance of glass, metal and un-insulated concrete and masonry is minimal. For example, the total thermal resistance of a single-pane window is about 1 hr-ft2-F/Btu and over 90% of the thermal resistance is from the interior and exterior 14 convection coefficients. Thus, adding insulation to these building components dramatically reduces heat loss. The cost-effectiveness of adding insulation decreases as the level of existing insulation increases. The figure below shows the diminishing returns from adding insulation with thermal resistance of 10 hr-ft2-F/Btu to a building component as a function of the initial thermal resistance of the component. As shown below, adding insulation with thermal resistance of 10 hr-ft2-F/Btu to a wall with an initial thermal resistance of 1 hr-ft2-F/Btu results in 16 times more energy savings than adding the same amount of insulation to a wall with an initial thermal resistance of 10 hr-ft2-F/Btu. 90,000 80,000 Savings (Btu/ft2-yr) 70,000 60,000 50,000 40,000 30,000 20,000 10,000 0 0 2 4 6 8 10 12 14 16 18 20 Initial R-Value Heat loss savings from adding R = 10 hr-ft2-F/Btu insulation to a building component plotted against the initial thermal resistance of the building component when Tia – Toa = 35 F. Common ways of adding insulation to under-insulated building components include: o Spray-on insulation for under-insulated walls o Increase roof insulation when replacing roof o Add double-polycarbonate sheets over windows o Replacing un-insulated dock doors with insulated dock doors Example: Inverse DD Method Model coefficients of 3PH model of natural gas use for a facility in Dayton, OH are: HS = 88.5 (mmBtu/mo-F) 15 Tb = 63.8 (F) Independent NG use = 0.00 (mmBtu/mo) The indoor air temperature is 70 F. The facility is heated by a mix of 100% efficient make-up air units and 80% efficient indoor air heaters; with an average heating efficiency of 90%. Calculate the annual fuel savings if the R value of the 200,000 ft 2 roof is increased from R = 3 hr-ft2-F/Btu to R = 6 hr-ft2-F/Btu during a required resurfacing of the roof. Solution: The initial heating coefficient, HC1, is: HC1 = HS Effh = 88.5 (mmBtu/mo-F) x 0.90 x 10^6 Btu/mmBtu / 730 hours/month HC1 = 109,110 (Btu/hr-F) The internal heat gain, Qi, is: Qi = HC1 (Tia - Tb) = 109,110 (Btu/hr-F) (70.0 – 63.8) F = 676,479 (Btu/h) The initial HDDs calculated with Tb = 63.8 F for Dayton, OH are about: HDD(64 F) = 5,655 (F-day/year) The initial annual fuel use is: Qf1 = HC / Effh HDD(Tb) Qf1 = 109,110 (Btu/hr-F) / 0.90 5,655 (F-day/year) x 24 (hours/day) / 106 (Btu/mmBtu) Qf1 = 16,454 (mmBtu/yr) Heat transfer through the roof is: Qr = A / R (Tia-Toa) Thus, the heating coefficient for the roof, HCr, is: HCr = Ar / Rr The change in the heating coefficient from insulating the roof, HC, is: HC = A / R1 - A / R2 = A (1 /R1 – 1 / R2) HC = 200,000 ft2 x (1/3 – 1/6) Btu/hr-ft2-F = 33,333 Btu/hr-F The new heating coefficient, HC2, would be: 16 HC2 = HC1 - HC = 109,110 (Btu/hr-F) – 33,333 (Btu/h-F) = 75,777 (Btu/h-F) The new balance temperature would be: Tb2 = Tia - Qi/HC2 = 70 F - 676,479 (Btu/h) / 75,777 (Btu/h-F) = 61.1 (F) The new HDDs calculated with Tb = 61.1 F for Dayton, OH are about: HDD2(61 F) = 4,939 (F-day/year) The new annual fuel use is: Qf2 = HC2 / Effh HDD2(Tb) Qf2 = 75,777 (Btu/hr-F) / 0.90 4,939 (F-day/year) x 24 (hours/day) / 106 (Btu/mmBtu) Qf2 = 9,980 (mmBtu/yr) Annual fuel savings are: Qfs = Qf1 – Qf2 = 16,454 (mmBtu/yr) - 9,980 mmBtu/yr = 6,473 mmBtu/yr Heating fuel use before and after the proposed change is plotted against outdoor air temperature in the figure below. The reduction in heat loss through the roof reduced the heating slope and reduced the heating balance temperature. 6,000 Qf (mmBtu/mo) 5,000 4,000 Qf1 Qf2 3,000 2,000 1,000 0 0 10 20 30 40 50 60 70 80 90 100 Toa (F) 17 If no 3PH model of natural gas use versus outdoor air temperature is available, similar results could be obtained by estimating envelope area, thermal resistance, ventilation rate and effective internal heat gain. The following example demonstrates this procedure. Example: Forward DD Method Consider a facility in Dayton, Ohio whose length is 500 ft, width is 400 ft and ceiling height is 30 ft. The walls have 10 ft-high single-pane windows with thermal resistance 1 hr-ft2-F/Btu on all sides. The thermal resistance of the roof is 3 hr-ft2-F/Btu, the thermal resistance of the walls is 10 hr-ft2-F/Btu. The ventilation rate is 19,000 cfm and the average electrical power requirement of equipment in the facility is 200 kW. The indoor air temperature is 70 F. The facility is heated by a mix of 100% efficient make-up air units and 80% efficient indoor air heaters; with an average heating efficiency of 90%. Calculate the annual fuel savings if the R value of the 200,000 ft 2 roof is increased from R = 3 hr-ft2-F/Btu to R = 6 hr-ft2-F/Btu during a required resurfacing of the roof. Solution: The areas, thermal resistances and heating coefficients (A / R) of the primary envelope components are shown in the table below. Ac Aw Awin Total A 200,000 36,000 18,000 254,000 R 3 10 1 A/R 66,667 3,600 18,000 88,267 Thus, the envelope A/R is 88,267 Btu/hr-F. The product of the ventilation rate, air density and specific heat is: 19,000 cfm x 0.018 Btu/ft3-F x 60 min/hr = 20,520 Btu/hr-F The initial heating coefficient, HC1, is: HC1 = 88,267 Btu/hr-F + 20,520 Btu/hr-F = 108,787 (Btu/hr-F) The internal heat gain, Qi, is: Qi = Qe x 3,412 Btu/hr = 200 kW x 3,412 Btu/kWh = 682,600 (Btu/h) The initial balance temperature is: Tb = Tia – Qi / HC1 = 70 F - 682,600 (Btu/h) / 108,787 (Btu/h-F) = 63.7 (F) 18 The initial HDDs calculated with Tb = 63.7 F for Dayton, OH are about: HDD(64 F) = 5,655 (F-day/year) The initial annual fuel use is: Qf1 = HC / Effh HDD(Tb) Qf1 = 108,787 (Btu/hr-F) / 0.90 5,655 (F-day/year) x 24 (hours/day) / 106 (Btu/mmBtu) Qf1 = 16,405 (mmBtu/yr) As before, heat transfer through the roof is: Qr = A / R (Tia-Toa) Thus, the heating coefficient for the roof, HCr, is: HCr = Ar / Rr The change in the heating coefficient from insulating the roof, HC, is: HC = A / R1 - A / R2 = A (1 /R1 – 1 / R2) HC = 200,000 ft2 x (1/3 – 1/6) Btu/hr-ft2-F = 33,333 Btu/hr-F The new heating coefficient, HC2, would be: HC2 = HC1 - HC = 108,787 (Btu/hr-F) – 33,333 (Btu/h-F) = 75,454 (Btu/h-F) The new balance temperature would be: Tb2 = Tia – Qi / HC2 = 70 F - 682,600 (Btu/h) / 75,454 (Btu/h-F) = 61.0 (F) The new HDDs calculated with Tb = 61.0 F for Dayton, OH are about: HDD2(61 F) = 4,939 (F-day/year) The new annual fuel use is: Qf2 = HC2 / Effh HDD2(Tb) Qf2 = 75,454 (Btu/hr-F) / 0.90 4,939 (F-day/year) x 24 (hours/day) / 106 (Btu/mmBtu) Qf2 = 9,938 (mmBtu/yr) Annual fuel savings are: 19 Qfs = Qf1 – Qf2 = 16,405 (mmBtu/yr) - 9,938 mmBtu/yr = 6,467 mmBtu/yr Heating fuel use before and after the proposed change is plotted against outdoor air temperature in the figure below. The reduction in heat loss through the roof reduced the heating slope and reduced the heating balance temperature. 6,000 Qf (mmBtu/mo) 5,000 4,000 Qf1 Qf2 3,000 2,000 1,000 0 0 10 20 30 40 50 60 70 80 90 100 Toa (F) Reduce Ventilation Loads The method to calculate savings from reducing ventilation loads is the same as for adding insulation. In each case, the heating coefficient is reduced and new balance temperatures must be calculated to estimate savings. Common ways of reducing ventilation loads include: o o o o o Seal exhaust fan openings Close dock doors using motion sensors or garage door openers Turn off dust collectors when not in use Turn off unnecessary exhaust air fans during winter Introduce make-up air near exhaust air locations Use Programmable Thermostats to Reset Temperature during Unoccupied Periods Lower interior set-point temperatures during unoccupied periods during the heating season lowers heating loads. Similarly, increasing interior set-point temperatures during 20 unoccupied periods during the cooling season lowers cooling loads. Small reductions in set-point temperature can significantly reduce heating and cooling energy use, because the heating and cooling loads are proportional to difference between indoor and outdoor air temperature. For example, if Toa = 50 F, then reducing Tia from 70 F to 60 F decreases heating load by 50%. A steady state analysis of heating and cooling energy use with modified temperature set-points would simply modify the average indoor air temperature to determine reduced heating and cooling loads. However, in practice, the thermal mass of the building reduces interior temperature swings and hence reduces savings. For example, the graph below shows set-point and indoor air temperatures over a 24 hour period for a building with a night temperature set back. The set-point temperature is reduced from 70 F to 60 F overnight, but the actual indoor air temperature does not reach 60 F until 8 am. Because the heating load is driven by the difference between the actual indoor air temperature and the outside air temperature, the actual reduction in heating load is less than would be estimated using a steady-state analysis. Thus, thermal mass effects reduce the savings estimated using steady state analysis. 75 70 T (F) 65 60 55 50 0 5 10 15 20 25 Hour of Day Tia (F) Tsetpoint (F) For example, in the Figure above the heating load reduction during the unoccupied period calculated using a steady state analysis, Qs,ss, would be about: Qs,ss = HC (70 – 60) = 10 HC However, a dynamic analysis shows that the actual average indoor air temperature during the set back period is about 64 F, rather than 60 F. Thus, the heating load reduction during the unoccupied period calculated using a dynamic analysis, Qs,d, would be about: 21 Qs,d = HC (70 – 64) = 6 HC It follows that the actual savings would be about 60% of the savings estimated using a steady state analysis. Example: Inverse DD Method Model coefficients of 3PH model of natural gas use for a facility in Dayton, OH are: HS = 88.5 (mmBtu/mo-F) Tb = 63.8 (F) Independent NG use = 0.00 (mmBtu/mo) The indoor air temperature is 70 F. The facility is heated by a mix of 100% efficient make-up air units and 80% efficient indoor air heaters; with an average heating efficiency of 90%. Calculate the annual fuel savings if the average indoor air temperature were reduced to 66 F by reducing thermostat set point temperature during unoccupied hours. Assume the actual savings would be about 60% of the savings estimated using a steady state analysis. Solution: The initial heating coefficient, HC1, is: HC1 = HS Effh = 88.5 (mmBtu/mo-F) x 0.90 x 10^6 Btu/mmBtu / 730 hours/month HC1 = 109,110 (Btu/hr-F) The internal heat gain, Qi, is: Qi = HC1 (Tia - Tb) = 109,110 (Btu/hr-F) (70.0 – 63.8) F = 676,479 (Btu/h) The initial HDDs calculated with Tb = 63.8 F for Dayton, OH are about: HDD(64 F) = 5,655 (F-day/year) The initial annual fuel use is: Qf1 = HC / Effh HDD(Tb) Qf1 = 109,110 (Btu/hr-F) / 0.90 5,655 (F-day/year) x 24 (hours/day) / 106 (Btu/mmBtu) Qf1 = 16,454 (mmBtu/yr) The new balance temperature would be: Tb2 = Tia2 - Qi/HC = 66 F - 676,479 (Btu/h) / 109,110 (Btu/h-F) = 59.8 (F) 22 The new HDDs calculated with Tb = 59.8 F for Dayton, OH are about: HDD2(60 F) = 4,711 (F-day/year) The new annual fuel use is: Qf2 = HC / Effh HDD2(Tb) Qf2 = 109,110 (Btu/hr-F) / 0.90 4,711 (F-day/year) x 24 (hours/day) / 106 (Btu/mmBtu) Qf2 = 13,707 (mmBtu/yr) Annual fuel savings are: Qfs = Qf1 – Qf2 = 16,454 (mmBtu/yr) - 13,707 mmBtu/yr x 60% = 2,747 mmBtu/yr Heating fuel use before and after the proposed change is plotted against outdoor air temperature in the figure below. The reduction in indoor air set-point temperature reduced the heating balance temperature, while the heating slope remained constant.. 6,000 Qf (mmBtu/mo) 5,000 4,000 Qf1 Qf2 3,000 2,000 1,000 0 0 10 20 30 40 50 60 70 80 90 100 Toa (F) Heating Delivery Effectiveness Ventilation rates in industrial facilities are frequently 6 to 8 air changes per hour compared to an average infiltration rate of less than 1 air change per hour for residences. At high ventilation rates, most of the space heating or cooling energy added/removed from the space is due to ventilation, it is important that heating systems be designed to deliver the heat where it is needed. Heat added near the ceiling 23 can easily be swept out without delivering any warmth to the occupants. For this reason, gas-fired IR heaters, which warm the floor and equipment, are often cost effective. In general, we assume that the effective efficiency of IR heaters is 25% better than space heaters. To avoid cold spots near doors or openings in the envelope of the building, it is necessary to balance the airflow into and out of the building. In buildings with negative pressure, cold air is sucked in making it very uncomfortable for the occupants. In these cases, add gas-heated make-up air units until the airflow is balanced. Case Study of Reducing Ventilation and Balancing Plant Air Pressure Ventilation rates in industrial facilities are frequently 6 to 8 air changes per hour compared to an average infiltration rate of less than 1 air change per hour for residences. At high ventilation rates, most of the space heating or cooling energy added/removed from the space is simply to heat or cool the ventilation air. Thus, reducing unnecessary ventilation yields large heating and cooling savings. A plant instituted an employee awareness program to balance plant air pressure during winter and reduce space heating costs. The program encouraged workers to do two things. First, turn off exhaust fans when not needed. Second, if cooling was needed, turn on a make up air unit which directed cool air into the overheated zone and pushed warm air from the zone to cooler area in the plant. Gas use from before and after the program was analyzed below to determine the effectiveness of the program. A time series graph of pre and post-program gas use is shown below, with pre gas use in blue and post gas use in red. The graph shows that gas use increases during winter and is near zero during summer, and that winter gas use is significantly less after the program was instituted. However, the reduction could have been caused by a warmer winter during the post period. 24 The graph below shows XY plots of pre and post gas use versus average outdoor air temperature, with 3PH models of each graph. Both models have R2 values of 0.97, which indicates that the models accurately predict gas use as a function of outdoor air temperature. The models show that at any given temperature, gas use decreased during the post period. Thus, the reduction was not caused by warmer weather. The reduction in the facility’s heating coefficient both reduced the heating slope and reduced the facility’s balance temperature. 25 The graph below shows a time series view of pre and post gas use, with the weatheradjusted baseline superimposed over the post gas use. Savings are represented by the difference between the adjusted baseline and the post gas use. Winter gas use in post period was 2,980 mmBtu. Winter weather-adjusted baseline gas use was 6,117 mmBtu. Winter weather-adjusted savings were 3,137 mmBtu, which represents a reduction of about 51%. This example demonstrates the importance of reducing air flow through a facility and balancing indoor/outdoor plant air pressure during winter. Cooling System Efficiency The principle types of cooling units used in manufacturing facilities are: Roof-top units Air handlers and chillers Rooftop Units Rooftop units are packaged heating, ventilating and air conditioning units that include air handler, heating and cooling coils, combustion or electric heating, and direct expansion cooling. In most rooftop units, outdoor and return air are mixed before entering a supply air fan that moves the air over a heating coil and then a cooling coil before delivering it to the facility. If heat is provided to the heating coil by natural gas, the heating efficiency is typically 80%. If heat is provided to the heating coil by electricity, the heating efficiency is 100%. The cooling coils contain refrigerant that passes though an expansion valve to reduce refrigerant pressure and temperature before entering the cooling coil. This type of cooling is called direct expansion cooling, in comparison to cooling coils that contain chilled water from a chiller. The average 26 efficiency of direct expansion air conditioners is reported as Seasonal Energy Efficiency Rating (SEER) in units of Btu of heat removed per W-hr of electricity consumed. SEER includes the electricity consumed by the air conditioner compressor, condenser fans and evaporator (supply air) fans. Minimum SEER requirements have increased over the years. In 2007, the minimum SEER for a new rooftop unit was increased to 12 Btu/W-hr. Air Handlers and Chillers In most air handlers, outdoor and return air are mixed before entering a supply air fan that moves the air over a heating coil and then a cooling coil before delivering it to the facility. Heat is typically delivered to the heating coil as hot water or steam. Cooling is typically delivered to the cooling coil as chilled water. Hence, the heating and cooling efficiencies are the efficiencies of the boilers and chillers that supply heating and cooling to the air handlers. The efficiency of air-cooled electric chillers is reported as Energy Efficiency Rating (EER) in units of Btu of heat removed per Wh of electricity consumed. EER is typically reported for specific operating conditions such as entering condenser and evaporator air temperatures; thus EER is not a seasonal average. EER includes the electricity consumed by the chiller compressor and condenser fans, but not by the chilled water distribution pumps. The efficiency of water-cooled electric chillers is typically characterized in terms of kW of electricity consumed by the compressor per ton of heat removed. kW/ton ratings are typically reported for specific operating conditions and not as seasonal averages. Further kW/ton ratings do not include the electricity consumed by the condenser pumps, cooling tower fans or chilled water distribution pumps. The efficiency of absorption chillers is typically characterized as non-dimensional COP and is about 1 unit of cooling produced per unit of heat required. Calculating Cooling Energy Use Calculating Hourly Cooling Energy Use Cooling loads in manufacturing facilities are primarily driven by heat gain through the building envelope, cooling ventilation or infiltration air, and internal heat gains. The rate of heat gain through the building envelope, Qenv, is: Qenv = A / R (Toa – Tia) The rate of sensible heat gain with ventilation or infiltration air, Qair,s, is: Qair,s = V pcp (Toa – Tia) 27 The rate of latent heat removed from ventilation or infiltration air by the air conditioner, Qair,l, is: Qair,l = V p hfg (woa – wda)+ Where V is the air flow rate, p is the air density, hfg is the enthalpy of evaporation of water, woa is the outside air specific humidity and wda is the specific humidity of air discharged by the air conditioner. For water at atmospheric pressure, the enthalpy of evaporation is about: hfg = 970 Btu/lb For air at standard conditions, the density is about: p = 0.075 lbs/ft3 Most air conditioners discharge saturated air at about 58 F, and the specific humidity is about: wda = 0.011 lbw/lba For air conditioners controlled by thermostats, the air conditioner will operate when the net sensible cooling load is positive. When operating, the latent cooling will become part of the load. Thus, the net cooling load, Qc, is If (Qenv + Qair,s + Qi) > 0 then Qc = (Qenv + Qair,s + Qi) + Qair,l Else Qc = 0 End if To maintain the facility at a constant temperature, the cooling system must remove heat at the same rate that heat is gained. The electricity consumed by the cooling system, Qe, must take into account the efficiency of the cooling system, Effc. Qe = Qc / Effc Example Problem: Calculate hourly cooling electricity use for a facility with the following characteristics: Length = 250 feet, width = 200 feet, ceiling height = 35 feet Average thermal resistance of walls and ceilings = 10 ft2-F-hr/Btu Average ventilation rate = 10,000 cfm 28 Indoor air temperature = 70 F Outdoor air temperature = 85 F Outdoor air temperature specific humidity = 0.013 lbw/lba Average facility electricity use = 100 kW Air conditioner SEER = 12 Btu/Wh Solution: A = (250 + 200 + 250 + 200) ft x 35 ft + (250 ft x 200 ft) = 81,500 ft 2 Qenv = A / R (Toa – Tia) = 81,500 ft2 / 10 ft2-F-hr/Btu x (85 – 70) F = 122,250 Btu/h Qair,s = V pcp (Toa – Tia) = 10,000 cfm x 60 min/hr x 0.018 Btu/F-ft3 x (85 – 70) F = 162,000 Btu/h Qair,l = V p hfg (woa – wda) = 10,000 cfm x 60 min/hr x 0.075 lba/ft3 x 970 Btu/lbw x (0.013 – 0.011) lbw/lba = 87,300 Btu/h Qi = 100 kW x 3,413 Btu/kWh = 341,300 Btu/h Determine if Qenv + Qair,s + Qi > 0: (122,250 + 162,000 + 341,300) Btu/h > 0 Qc = Qenv + Qair,s + Qair,l + Qi = (122,250 + 162,000 + 87,300 + 341,300) Btu/h = 712,850 Btu/h Qe = Qc / Effc = 712,850 Btu/hr / (12 Btu/Wh x 1,000 W/kW) = 59 kWh/h Calculating Annual Cooling Energy Use To calculate annual cooling electricity use, sum hourly values over the year. Example Problem: Calculate annual cooling electricity use for a facility with the following characteristics: Length = 250 feet, width = 200 feet, ceiling height = 35 feet Average thermal resistance of walls and ceilings = 10 ft2-F-hr/Btu Average ventilation rate = 10,000 cfm Indoor air temperature = 70 F Average facility electricity use = 100 kW Air conditioner SEER = 12 Btu/Wh Located in Dayton, Ohio Solution: A = (250 + 200 + 250 + 200) ft x 35 ft + (250 ft x 200 ft) = 81,500 ft 2 Qenv = A / R (Toa – Tia) = 81,500 ft2 / 10 ft2-F-hr/Btu x (Toa – 70) F Qair,s = V pcp (Toa – Tia) = 10,000 cfm x 60 min/hr x 0.018 Btu/F-ft3 x (Toa – 70) F Qair,l = V p hfg (woa – wda) = 10,000 cfm x 60 min/hr x 0.075 lba/ft3 x 970 Btu/lbw x (woa – 0.011)+ lbw/lba Qi = 100 kW x 3,413 Btu/kWh = 341,300 Btu/h When (Qenv + Qair,s + Qi) > 0, Qc = (Qenv + Qair,s + Qi) + Qair,l Qc = Qc dt = 1,342 mmBtu/yr 29 Qe = Qc / Effc = 1,342 mmBtu/yr x 106 Btu/mmBtu / (12 Btu/Wh x 1,000 W/kW) = 111,805 kWh/yr Bin Temperature Analysis using TMY2 Data for Dayton Ohio Qi Qair,l Qair,s NumHrs Qenv StrTemp EndTemp AvgT Avg w (Btu/h) (Btu/h) (Btu/h) (Btu/h) (lbw/lba) (F) (F) (F) ======== ======== ======== ======== ======== ======== ======== ======== ======== 1 171,150 226,800 178,965 341,300 91.0 0.0151 94 90 87 138,550 183,600 126,585 341,300 87.0 0.0139 89 85 74,205 341,300 338 99,430 131,760 82.2 0.0127 84 80 43,650 341,300 73,440 502 55,420 76.8 0.0120 79 75 34,920 341,300 25,920 661 19,560 72.4 0.0118 74 70 0 341,300 -22,680 865 -17,115 67.9 0.0106 69 65 0 341,300 -82,080 943 -61,940 62.4 0.0088 64 60 0 341,300 735 -105,950 -140,400 57.0 0.0072 59 55 0 341,300 644 -146,700 -194,400 52.0 0.0059 54 50 0 341,300 505 -184,190 -244,080 47.4 0.0047 49 45 0 341,300 644 -218,420 -289,440 43.2 0.0042 44 40 0 341,300 713 -264,875 -351,000 37.5 0.0034 39 35 0 341,300 726 -308,885 -409,320 32.1 0.0027 34 30 0 341,300 438 -346,375 -459,000 27.5 0.0021 29 25 0 341,300 343 -381,420 -505,440 23.2 0.0017 24 20 0 341,300 292 -426,245 -564,840 17.7 0.0013 19 15 0 341,300 156 -471,070 -624,240 12.2 0.0010 14 10 0 341,300 87 -511,005 -677,160 7.3 0.0008 9 5 0 341,300 50 -548,495 -726,840 2.7 0.0007 4 0 0 341,300 29 -581,095 -770,040 -1.3 0.0005 -1 -5 0 341,300 1 -612,065 -811,080 -5.1 0.0005 -6 -10 ======== ======== ======== ======== ======== ======== ======== ======== ======== 8,760 Totals Qc Qc (Btu/h) (mmBtu) ======== ======== 1 918,215 69 790,035 219 646,695 258 513,810 279 421,700 261 301,505 186 197,280 70 94,950 0 200 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 ======== ======== 1,342 30