evolution of production medicine

advertisement

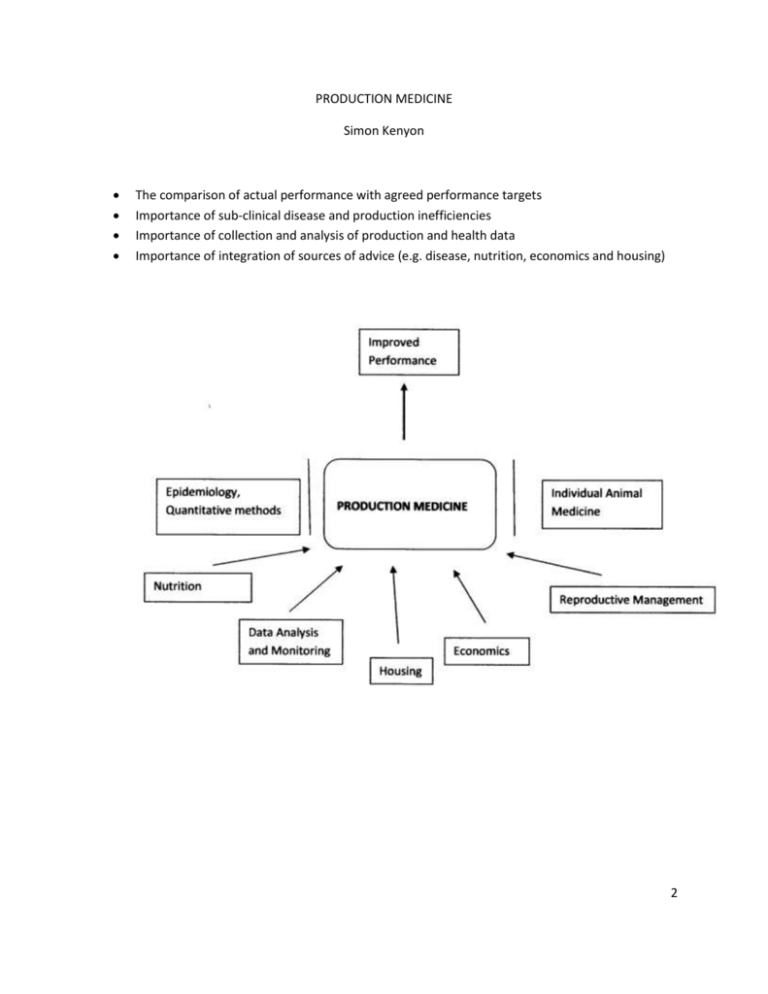

PRODUCTION MEDICINE Simon Kenyon The comparison of actual performance with agreed performance targets Importance of sub-clinical disease and production inefficiencies Importance of collection and analysis of production and health data Importance of integration of sources of advice (e.g. disease, nutrition, economics and housing) 2 EVOLUTION OF PRODUCTION MEDICINE Area based disease control programs 1870’s Individual animal treatment 1940’s Health programs for control of specific diseases 1960’s Integration of health maintenance with production management 1980’s THE VETERINARIAN AND PRODUCTION MEDICINE Has the necessary veterinary skill Understands the production system Understands and uses data management techniques Can participate in and manage the advisory team Aware of the economics of production and the effects of disease Is a positive promoter of animal welfare, food safety and environmental protection 3 On Farm Troubleshooting of Nutritional Problems Presentation Production problems Reproduction problems Metabolic diseases Peri-parturient disease Foot problems Farm Visit Charge by the hour DHIA records Peak milk 150 day milk Persistency Days to 1st service Culling records Milk Fat:Protein ratio Check tanker pick-up slips Try and get there when feed is put out. Collect data and information and arrange to come back to discuss at farm meeting. Feeds Always get your own forage samples Examine feeds for overheating, spoilage etc Particle size analysis for forages Check fineness of grind of corn Be aware of effect on feed mixture of a moisture change in a major component. Check moisture content using microwave to dry samples. Feed mixing Order in which feeds added to the TMR mixer Awareness of impact of moisture changes in forages Time the mixer. Adequately mixed? Over-mixed? Take samples of TMR from feed bunk and check with Penn State Forage Separator Check moisture content of ration as fed. May wish to send TMR sample for proximate analysis by chemical methods as check on mixing. Feed Bunk How many times/ day are cows fed. How long is bunk empty. What is left in the bunk? Nothing? Cobs? Spoiled feed? How many feet of bunk space for how many cows. How many feet of bunk has feed in it? If poor man’s, TMR how many hay feeders are available? 2 Water How many waterers? Are they clean? Is water always available? Tempered water from plate cooler? Is there room around waterers. Often in passthrough between free-stall alleys. Free- stalls Size & condition What bedding material? Is it groomed? Ventilation. Cow to free-stall ratio Look at Cows Body condition score cows by lactation number and stage of lactation & plot on chart. How do cows move? Lame cows? Overgrown hooves? Scuffed hocks? What are cows doing? How are cows using freestalls. Lying? Standing? How many are cud-chewing? Manure Color/ odor Consistency of manure. All the same? Some loose/ some firm? How much grain in manure. Ration formulation Look especially at ration moisture, ADF, NDF, NFC , NEl,, CP, heat damaged protein for major errors Potassium levels in dry cow hay? Adequate buffer in lactating ration? High levels soluble protein or NPN? Special examinations Feed analyses Mycotoxin screen? Pick up and examine feet. Penn State Forage Separator BUN or MUN Herd based rumenocentesis Urine pH on close-up dry cows fed DCAD ration Follow-up Try some ration ideas using the values from you feed analyses ? By-product suggestions Written agenda for farm meeting Meet nutritionist at farm to discuss. Walk through again with meeting participants and then meet somewhere comfortable. Written summary of meeting to all participants 2 BEEF CATTLE PRACTICE Cow-calf and small feedlot Large cow-calf operations Feedlot practice Cow-calf practice: Seasonal Sick cow work Vaccination & Deworming programs Preconditioning Farm records and financial performance Glossary Backgrounding- A management system for a weaned calf in which the animal is grown for a period of time (generally 2 to 6 months) prior to being finished. Diets and weight gains vary during this time period. Bunk breaking - The process of acclimating calves to consume feed from a bunk or other feeder. Calf-feds - Cattle which are placed on feed as calves and finished at less than 16 months of age. They are usually on feed for 150 to 200 days. These cattle are usually placed in the feedlot directly following weaning. Carcass merit - Desirability of a carcass relative to quantity of muscle, fat, bone, and quality of lean tissue. Many packer estimate carcass merit by measuring backfat and one or more other indicator traits such as carcass weight. Carrying capacity - The maximum stocking rate possible without damaging vegetation or related resources. Carrying capacity may vary from year to year on the same area, due to fluctuating forage production. Concentrated Animal Feeding Operation (CAFO) - Animal feeding operations with at least 1,000 animal units (1,000 head of cattle). Custom feedyard - A feedyard which feeds, manages, and markets cattle for customers. Fees are charged for materials and services. 3 Double muscling- A genetic trait in cattle where muscles are greatly enlarged rather than duplicate muscles Dressing percentage- The percentage of the live animal weight that becomes the carcass weight at slaughter. It is determined by dividing the carcass weight by the live weight, then multiplying by 100. Expected Progeny Difference- One-half of the breeding value; the difference in performance to be expected from future progeny of a sire, compared with that expected from future progeny of an average bull in the same test. Grade- (1) A designation of live or carcass merit-e.g., choice grade. (2) Livestock not registered with registry association. Heterosis - The improvement in production observed or measured in crossbred animals compared with the average of their purebred parents; hybrid vigor. Marbling- The distribution of fat in muscular tissue; intramuscular fat. Market class- Animals grouped according to the use to which they will be put, such as slaughter, feeder, or stocker. Pay weight- The actual weight for which payment is made. In many cases it is the shrunk weight (actual weight minus pencil shrink). Preconditioning - The process of preparing calves to enter the feedlot. It often includes weaning, bunk breaking, and vaccination for respiratory disease. Process verified program (PVP) - A PVP is a USDA approved Process Verified Program. A PVP requires a company or business entity to implement a Quality Management System, based upon ISO 9000 standards, to provide products or services which consistently meet specified product requirements. in the beef cattle industry, PVP's are usually used to verify the age and source of cattle for export to various foreign countries. Quality grades- Animals grouped according to value as Prime, Choice, etc., based on conformation and fatness of the animals. Radio frequency identification (RFID) - A method of identifying cattle by placing an electronic tag or button in their ear. The tags are read by a scanner attached to a hand-held or portable computer. Railer(s) - Cattle which fail to respond to treatment. Settle- To become pregnant Shrink- Loss of weight-commonly used in the loss in liveweight when animals are marketed. 4 Stocker- Weaned cattle that are fed high-roughage diets (including grazing) before going into the feedlot. Thermoneutral zone (TNZ) - Range in temperature where rate and efficiency gain is maximized. Comfort zone Yardage- Charges incurred each day that the cattle are in the feedlot. These charges vary depending on the lot. Yardage is usually expressed on a cents per head per day basis. Yield grades- The grouping of animals according to the estimated trimmed lean meat that their carcass would provide; cutability. 5