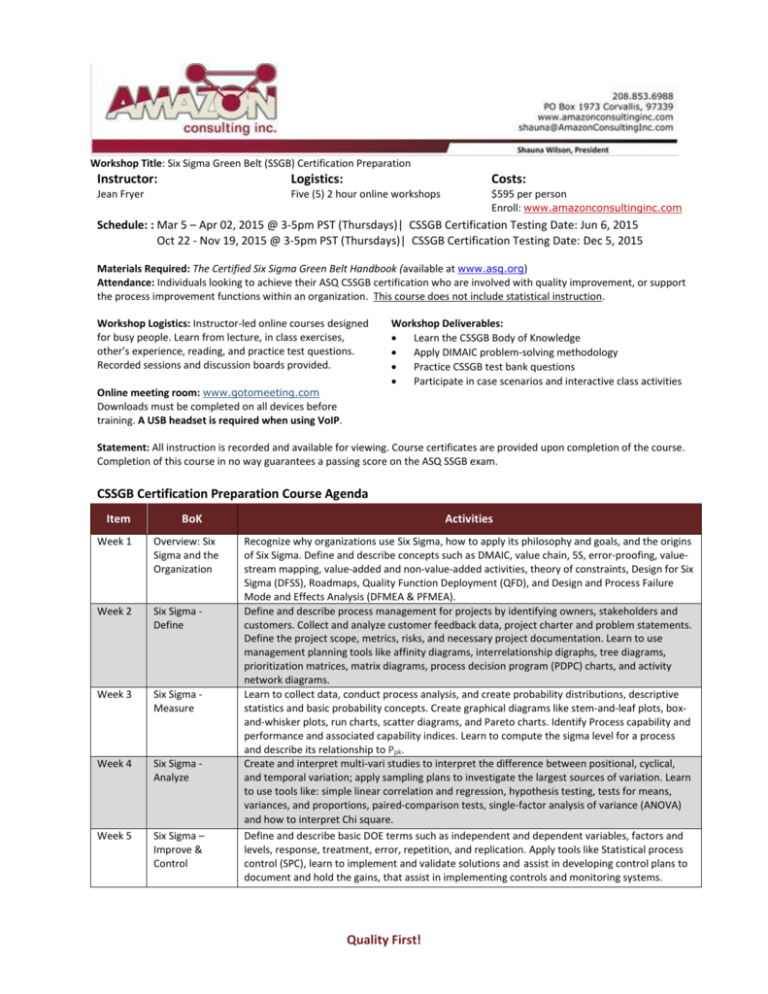

Class Details - Amazon Consulting, Inc.

advertisement

Workshop Title: Six Sigma Green Belt (SSGB) Certification Preparation Instructor: Logistics: Costs: Jean Fryer Five (5) 2 hour online workshops $595 per person Enroll: www.amazonconsultinginc.com Schedule: : Mar 5 – Apr 02, 2015 @ 3-5pm PST (Thursdays)| CSSGB Certification Testing Date: Jun 6, 2015 Oct 22 - Nov 19, 2015 @ 3-5pm PST (Thursdays)| CSSGB Certification Testing Date: Dec 5, 2015 Materials Required: The Certified Six Sigma Green Belt Handbook (available at www.asq.org) Attendance: Individuals looking to achieve their ASQ CSSGB certification who are involved with quality improvement, or support the process improvement functions within an organization. This course does not include statistical instruction. Workshop Logistics: Instructor-led online courses designed for busy people. Learn from lecture, in class exercises, other’s experience, reading, and practice test questions. Recorded sessions and discussion boards provided. Online meeting room: www.gotomeeting.com Downloads must be completed on all devices before training. A USB headset is required when using VoIP. Workshop Deliverables: Learn the CSSGB Body of Knowledge Apply DIMAIC problem-solving methodology Practice CSSGB test bank questions Participate in case scenarios and interactive class activities Statement: All instruction is recorded and available for viewing. Course certificates are provided upon completion of the course. Completion of this course in no way guarantees a passing score on the ASQ SSGB exam. CSSGB Certification Preparation Course Agenda Item BoK Week 1 Overview: Six Sigma and the Organization Week 2 Six Sigma Define Week 3 Six Sigma Measure Week 4 Six Sigma Analyze Week 5 Six Sigma – Improve & Control Activities Recognize why organizations use Six Sigma, how to apply its philosophy and goals, and the origins of Six Sigma. Define and describe concepts such as DMAIC, value chain, 5S, error-proofing, valuestream mapping, value-added and non-value-added activities, theory of constraints, Design for Six Sigma (DFSS), Roadmaps, Quality Function Deployment (QFD), and Design and Process Failure Mode and Effects Analysis (DFMEA & PFMEA). Define and describe process management for projects by identifying owners, stakeholders and customers. Collect and analyze customer feedback data, project charter and problem statements. Define the project scope, metrics, risks, and necessary project documentation. Learn to use management planning tools like affinity diagrams, interrelationship digraphs, tree diagrams, prioritization matrices, matrix diagrams, process decision program (PDPC) charts, and activity network diagrams. Learn to collect data, conduct process analysis, and create probability distributions, descriptive statistics and basic probability concepts. Create graphical diagrams like stem-and-leaf plots, boxand-whisker plots, run charts, scatter diagrams, and Pareto charts. Identify Process capability and performance and associated capability indices. Learn to compute the sigma level for a process and describe its relationship to Ppk. Create and interpret multi-vari studies to interpret the difference between positional, cyclical, and temporal variation; apply sampling plans to investigate the largest sources of variation. Learn to use tools like: simple linear correlation and regression, hypothesis testing, tests for means, variances, and proportions, paired-comparison tests, single-factor analysis of variance (ANOVA) and how to interpret Chi square. Define and describe basic DOE terms such as independent and dependent variables, factors and levels, response, treatment, error, repetition, and replication. Apply tools like Statistical process control (SPC), learn to implement and validate solutions and assist in developing control plans to document and hold the gains, that assist in implementing controls and monitoring systems. Quality First!