9 DRS

advertisement

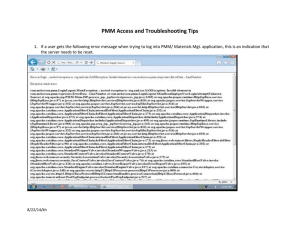

Motor / Generator Thermal Characterization Tests Sponsor: DRS Power Technoogy, Inc DRS Lead: Dr. Mark Majewski, mmajewski@drs-pt.com, Andy Judge, 166 Boulder Drive Suite 201, Fitchburg, MA 01420, 978-353-5244, ajudge@drs-pt.com Background and Problem: Permanent magnet machines (PMM’s) are enjoying more usage in the field of electromechanical power conversion. The basic physics of PMM’s consists of alternating poles of permanent magnets rotating past either a ferromagnetic material wrapped in conductive windings, or other magnets (with or without an intermediate ferrous material or conductive windings between them). For electromagnetic power conversion, either an input torque / RPM (ALT/GEN applications) or an input electrical voltage / current (motor applications) is supplied and the other provided as an output, providing electromechanical power conversion. While higher in cost, PMM’s offer numerous technical advantages compared to traditional “field wound” systems (where the magnetic field is created by a second system of ferromagnetic material wrapped in conductive windings powered by an input current), including: Higher efficiency. PMM’s do not experience rotor copper losses, stray load losses, or stator copper losses, which generate 40-50% of the inefficiencies of traditional induction machines. Higher reliability. PMM’s do not have “brushes” or slip rings to transfer power by directly linking rotating electrical wires to a stationary connection. These connections are a constant source of wear / fatigue failures in traditional electric motors and alternators. Higher power density. Permanent Magnets, especially high performance materials such as Neodymium/Iron/Boron, have exceptionally high magnetic flux densities, and can generate more power in low weight, small sized systems. One critical area in PMM performance is thermal management. Stator slots consist of copper windings, possible varnish coating, insulation (usually in multiple layers), possible adhesives / potting, air, and other materials. This provides quite a challenge in analysis, as this complex material system and their thermal contact resistances must be quantified in a model that must be detailed enough to provide accurate data, yet simplified enough that a Finite Element Model can be created with a size that can be run and iterated. For this first semester the anticipated output from this team will be a concept design of a test device that will allow DRS to run “test coupons” for a wide variety of large sized motors, including CAD models and related drawings. Second semester efforts may include the construction of the test device, and a trial run of a sample test item. Work Elements Students familiarize themselves with motor / generators and their operation 1 Students familiarize themselves with the desired test equipment and its operation Design test fixtures, including sample stators, mounting fixtures, etc. Develop a test plan Develop an analytical model of the unit under test. Perform the test in accordance with the plan Write a test report summarizing the data Analyze the results Compare the results to the analysis Technology Study Areas / Skills and Knowledge Electromagnetics Thermal Analysis Test Engineering CAD / Mechanical Layout (Test Fixtures, etc.) Fabrication Space Workbench Stator Slot Test Equipment o Safety shields as required o Power Source Computing Requirements 3D CAD System (Solidworks Preferred) Analysis Tool (ANSYS Preferred, Solidwork Simulation Acceptable) Office Tools (Word, Powerpoint, Excel, etc.) for data collection, reporting, and presentation 2