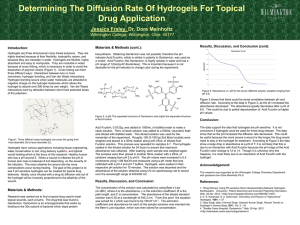

In situ gelling bioadhesive hydrogel for topical and mucosal

advertisement