Simple, fast and precise measurement of thermal systems In order to

advertisement

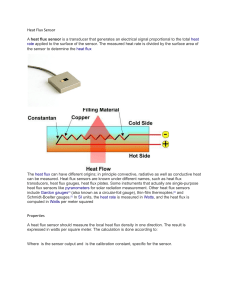

Simple, fast and precise measurement of thermal systems In order to optimize processes and materials with regards to their energy efficiency, precise data is a necessity. With the common measurement tools, however, fast and accurate assessment of thermal systems is a challenging task and questions like “How much heat does my house emit?”, “How strong is the solar radiation on a given day?” or “How much energy does a laser source produce?” remain tricky to answer. To simplify the measurement of thermal systems, greenTEG developed a new type of heat flux sensor which enables the easy, fast and precise measurements of thermal fluxes through solids, liquids, gases, and radiation. With highly sensitive, small and customizable features, the gSKIN Heat Flux Sensor enables a wide range of applications including material testing and process monitoring in R&D and industrial environments. Measurement of different types of heat fluxes There are three types of heat fluxes, which we all feel via our own sensor: our skin. Skin detects a slight breeze (convection), the exposure to a heat source like the sun (radiation) and the different conductive properties of materials (conduction) in the fraction of a second. The gSKIN Heat Flux sensor has the same properties as the human skin. The gSKIN Heat Flux Sensor measures the heat flux which flows through its surface with highly sensitive thermocouples. The thermocouples build-up a voltage which is proportional to the heat flux measured. A standard voltmeter or a data logger is sufficient as a read-out device. The heat flux is a thermal power per area and is measured in W/m2. The value is obtained by dividing the measured voltage value by the sensor specific sensitivity. Advantages of the gSKIN Heat Flux Sensor The gSKIN Heat Flux Sensor realizes its high sensitivity and fast reaction time on an extremely thin and small module with a low and homogeneous thermal resistance. This keeps the sensor’s thermal invasiveness low and enables precise and distortion-free measurements of heat fluxes without timeconsuming configuration of multiple sensors. While the gSKIN measures the thermal dynamics of a system (i.e. heat flux), temperature sensors measure the thermal status of a system (i.e. temperature). This property is advantageous as it allows simple measurements of thermal dynamics without configuring time consuming measurement setups involving temperature sensors. Furthermore, the gSKIN can be customized (size, protective coating, type and arrangement of contacts) for specific applications and thus deliver optimal results for various environments. Multitude of possible applications The high precision, the low thermal invasiveness, and fast response time of the gSKIN Heat Flux Sensor enables applications in various fields: as a design-in component in OEM products, in the research and development of processes and materials, and the control and measurement of industrial processes. Quantification of heat fluxes in buildings (energy efficiency) Quantification of different radiation sources (sun, laser) Measurements in the development of functional wear and protective gear Optimization of engines Supervision of body functions in humans and animals For further information visit: www.greenTEG.com or contact gSKIN@greenTEG.com.