Semi-Circular Notched Bending Fracture (SCNBF) Test

advertisement

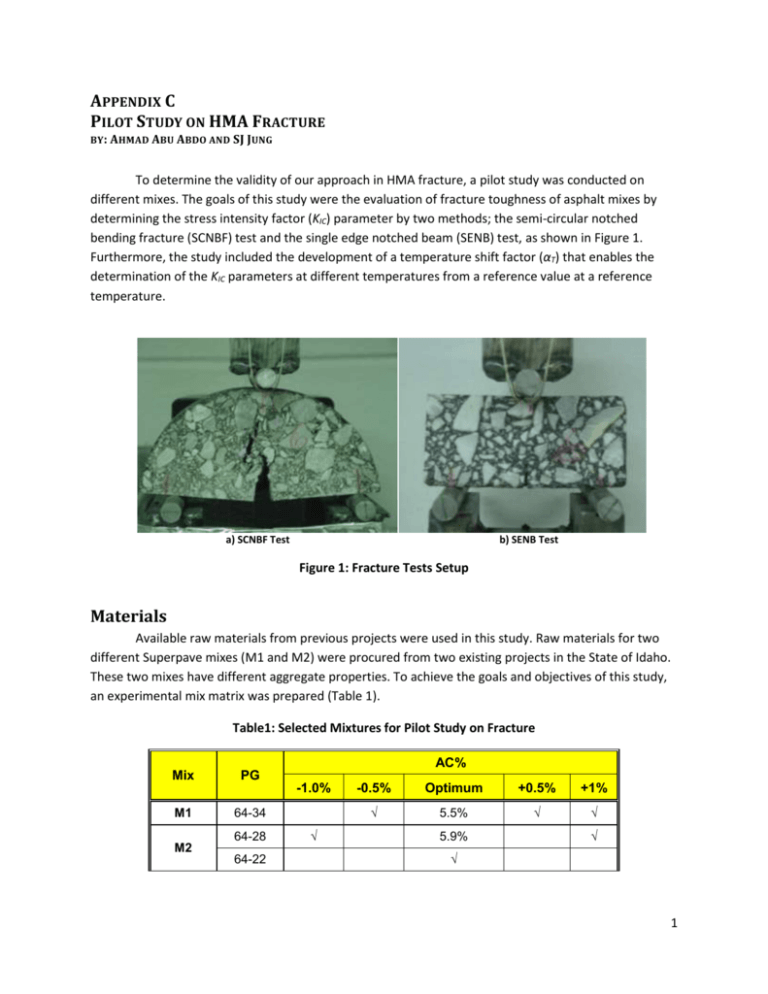

APPENDIX C PILOT STUDY ON HMA FRACTURE BY : AHMAD ABU ABDO AND SJ JUNG To determine the validity of our approach in HMA fracture, a pilot study was conducted on different mixes. The goals of this study were the evaluation of fracture toughness of asphalt mixes by determining the stress intensity factor (KIC) parameter by two methods; the semi-circular notched bending fracture (SCNBF) test and the single edge notched beam (SENB) test, as shown in Figure 1. Furthermore, the study included the development of a temperature shift factor (αT) that enables the determination of the KIC parameters at different temperatures from a reference value at a reference temperature. a) SCNBF Test b) SENB Test Figure 1: Fracture Tests Setup Materials Available raw materials from previous projects were used in this study. Raw materials for two different Superpave mixes (M1 and M2) were procured from two existing projects in the State of Idaho. These two mixes have different aggregate properties. To achieve the goals and objectives of this study, an experimental mix matrix was prepared (Table 1). Table1: Selected Mixtures for Pilot Study on Fracture AC% Mix PG -1.0% M1 M2 64-34 64-28 64-22 √ -0.5% Optimum +0.5% +1% √ 5.5% √ √ 5.9% √ √ 1 Sample Preparation and Tests Setup All specimens were mixed and compacted under controlled lab conditions. Specimens were compacted using the Servopac Gyratory Compactor to a number of gyrations to produce specimens with 4% air voids. For the optimum asphalt content for both mixes, the number of gyration coincided with their set N-design. Specimens used in a dynamic modulus test were compacted to achieve 170mm high specimens with a total of 9% air voids. Different samples were used for each test. Two replicates were prepared for each mix condition. Semi-Circular Notched Bending Fracture (SCNBF) Test Compacted cylindrical specimens were sliced into 4-quarter semi-circle specimens. One quarter is left un-notched as a control specimen, and the other three quarters were notched with 12.7, 25.4 and 31.8mm notch depths. All specimens have the standard Superpave Gyratory diameter (150mm). Spacing between the two roller supports was 120mm. A ramp load with a constant vertical deformation rate of 0.5mm/minute was applied till fracture occurred. Testing was conducted at temperatures of 4.4, 24 and 54.4 °C. Single Edge Notched Beam (SENB) Test Semi-circular specimens were sawed into beam specimens with dimensions of 100mm wide and 50mm high. Beams were notched with 12.7mm notch depth. Spacing between the two roller supports was 80mm. A ramp load with a constant vertical deformation rate of 0.5mm/minute was applied till fracture occurred. Testing was conducted at a room temperature of 24 °C. Dynamic Modulus |E*| Test All Specimens were cored and sawed to obtain specimens with a 100mm diameter, 150mm high and 7% air voids. The dynamic modulus test was conducted as per AASHTO TP 62-03 test protocol. Testing consists of applying a uniaxial sinusoidal compressive stress to an unconfined asphalt mix cylindrical test specimen under a series of loading frequencies (0.1, 1, 5, 10 and 25 Hz) at different temperatures (4.4, 21.1, 37.8 and 54.4 °C). Results and Analysis Geometry Effects Prior to conducting experimental tests to study the effect of geometry on fracture toughness, a simple 2-D Finite Element Analysis (FEA) was conducted for both geometries. Using the same material properties, loading and boundaries conditions, tensile stress at the tip of the notch was simulated. When loaded both test setups yielded approximately the same tensile stress at the tip of the notch; the stress at the tip of notch for SCNBF test setup was 8.07MPa (1170.67psi) and 7.53MPa (1092.12psi) for SENB test setup as shown in Figure 2. The difference is less than 7% of maximum tensile stress which can be caused by shape, size, and distribution of elements in the FEA model. Furthermore, KIC by SCNBF yielded 9.1MPa.m0.5 and 8.7MPa.m0.5 by SENB. The difference is less than 4.4%. Thus, with ideal conditions, there should be no significant difference in KIC by using either test setups. 2 a) SCNBF Test b) SENB Test Figure 2: Finite Element Analysis Results for three Point Loading Test Setup Next, to compare KIC determined by the two test setups, a statistical software package SAS was used. T-tests were conducted, to determine if there is any significant difference between the mean values of KIC for each mix condition. With a level of confidence of 95% (α = 0.05), results for the tested mixes showed that there was no significant difference between KIC by either SCNBF or SENB test setups (Figure 3). However, results of SENB were more scattered than SCNBF results. SENB 0.3 SCNBF KIC , MPa.m 0.5 0.25 0.2 0.15 0.1 0.05 0 M1(Opt-PG6434) M1(-0.5AC%) M2(Opt-PG6428) M2(+1AC%) M2(PG64-22) Figure 3: SCNBF versus SENB Tests Results Temperature Shift Factor (αT) Using the asphalt mix dynamic modulus |E*| test data; shift factors at 4.4 and 54.4 °C were developed for each mix conditions. KIC at room temperature were shifted to 4.4 and 54.4 °C temperatures. Using statistical t-test with a level of confidence α = 0.05, there was no significant difference between the actual and the shifted KIC at 54.4 °C as shown in Figure 4-a. On the other hand, 3 at 4.4 °C (Figure 4-b), there was no significant difference for Mix M1. The actual KIC values for Mix M2 were larger than the shifted KIC values. By studying the fracture surface for both mixes, Figure 5 illustrated that the crack in Mix M1 specimens mostly propagated through the binder and around the aggregates (Figure 5-a). In Mix M2, the crack has propagated through the binder and aggregates as shown in Figure 5-b. For the same binder content (M1(+0.5AC%-PG64-34) and M2(Opt-PG64-28)), it was expected that Mix M1 would exhibit higher fracture resistance than Mix M2 due to better binder grade (PG64-34). Results showed that Mix M2 yielded larger KIC than Mix M1. Even when using a lower binder grade (PG64-22) for Mix M2, Mix M2 still yielded higher KIC than Mix M1 (Figure 6). This might be rationalized by; at high temperature stiffness of binder is the controlling factor in asphalt mixes fracture resistance. At low temperatures, there are other factors (e.g. aggregate strength, shape, and texture) than binder stiffness that may affect fracture resistance, which may lead to higher KIC values. Further investigation is needed to adjust the shift factor to account for these factors for low temperatures. 0.08 Actual KIC 0.07 Shifted KIC KIC, MPa.m0.5 0.06 0.05 0.04 0.03 0.02 0.01 0.00 M1(-0.5AC%) M1(Opt-PG64- M1(+0.5AC%) 34) M2(-1AC%) a) 54.4°C Test Tem perature M2(OptPG64-28) Actual KIC 1.4 Shifted KIC 0.5 1.2 KIC, MPa.m M2(+1AC%) 1.0 0.8 0.6 0.4 0.2 0.0 M1(-0.5AC%) M1(Opt-PG64- M1(+0.5AC%) 34) M2(-1AC%) M2(OptPG64-28) M2(+1AC%) b) 4.4°C Test Tem perature Figure 4: Actual versus Predicted SCNBF Results at Different Temperatures 4 a) Mix M1 (Opt-PG64-34) b) Mix M2 (Opt-PG64-28)) Figure 5: Fracture Surface at 4.4°C 1.4 24°C 1.2 4.4°C 1.0 0.8 0.6 0.4 0.2 64 -2 2) % ) M 2( PG % pt -P 1A C M 2( O M 2( - M 2( +1 AC G 64 -2 8) ) ) % % pt -P M 1( O M 1( +0 .5 AC G 64 -3 4) 0.0 0. 5A C M 1( - 54.4°C KIC , MPa.m 0.5(4.4°C) 0.20 0.18 0.16 0.14 0.12 0.10 0.08 0.06 0.04 0.02 0.00 ) KIC , MPa.m 0.5(24 & 54.4 °C) According to the outcome of this study, and as expected, when evaluating KIC by SCNBF test at different temperatures, KIC was greater at low temperature of 4.4 °C and was lower at high temperature of 54.4 °C (Figure 6). For the tested mixes, it was found that KIC at any temperature ranked the tested mixes in the same pattern. KIC determined at room temperature of 24 °C followed almost the same trend of KIC at temperatures of 4.4 and 54.4 °C. Figure 6: Stress Intensity Factor KIC at Different Temperature Conclusions Based on the results of this pilot study, the following observations and conclusions are made: 1. When comparing the semi-circular notched bending fracture (SCNBF) test and the single edge notched beam (SENB) test, there was no significant difference at a level of confidence of 95% (α = 0.05) between results of the stress intensity factor (KIC) determined by both test setups. However, SENB test results were more scattered than SCNBF test results. 5 2. Utilizing the dynamic elastic modulus |E*| test data, a shift factor (αT) was developed. For the tested mixes, there was no significant difference between actual and shifted KIC at higher temperature than the reference temperature. At lower temperatures there was no significant difference for Mix M1. Unlike Mix M1, actual KIC for Mix M2 was larger than shifted KIC. It is believed that stiffness of binder at high temperature could be the controlling factor. At low temperatures, there are other factors (e.g. aggregate properties) that might lead to higher KIC. Further investigation is required to account for these factors at low temperature. 3. KIC by SCNBF test yielded as expected greater values at low temperature of 4.4 °C and low values at high temperature of 54.4 °C. Furthermore, it was observed that for the tested mixes KIC at room temperature (24 °C) followed the same trend of KIC determined at both temperatures 4.4 and 54.4 °C. KIC by SCNBF test at any temperature ranked the tested mixes in the same pattern. 4. For the range of tested mixes, results showed that Mix M2 would exhibit higher fracture resistance than Mix M1. Thus, Mix M2 would perform better that Mix M1 under the same loading conditions. 5. Overall, results suggested that semi-circular notched bending fracture (SCNBF) test is beneficial in characterizing the fracture resistance of asphalt mixes. SCNBF test is also simple and repeatable, it can be used as a screening tool at the mix design stage to assess the fracture resistance of mixes, and help to eliminate weak mixes before conducting more sophisticated and time consuming tests. 6