Word version

advertisement

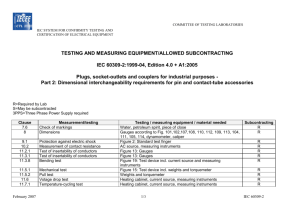

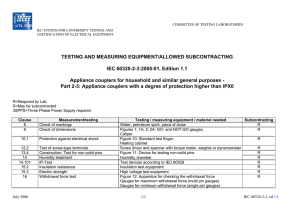

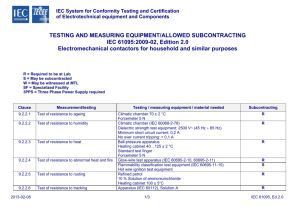

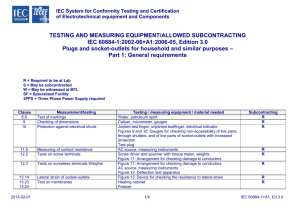

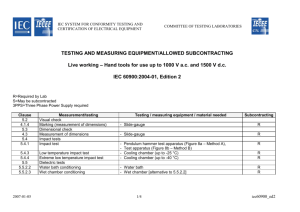

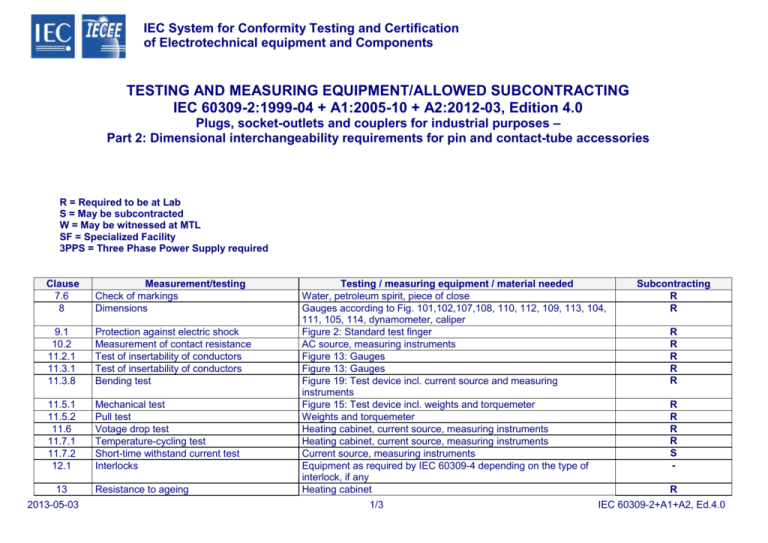

IEC System for Conformity Testing and Certification of Electrotechnical equipment and Components TESTING AND MEASURING EQUIPMENT/ALLOWED SUBCONTRACTING IEC 60309-2:1999-04 + A1:2005-10 + A2:2012-03, Edition 4.0 Plugs, socket-outlets and couplers for industrial purposes – Part 2: Dimensional interchangeability requirements for pin and contact-tube accessories R = Required to be at Lab S = May be subcontracted W = May be witnessed at MTL SF = Specialized Facility 3PPS = Three Phase Power Supply required Clause 7.6 8 Measurement/testing Check of markings Dimensions 9.1 10.2 11.2.1 11.3.1 11.3.8 Protection against electric shock Measurement of contact resistance Test of insertability of conductors Test of insertability of conductors Bending test 11.5.1 11.5.2 11.6 11.7.1 11.7.2 12.1 Mechanical test Pull test Votage drop test Temperature-cycling test Short-time withstand current test Interlocks 13 2013-05-03 Resistance to ageing Testing / measuring equipment / material needed Water, petroleum spirit, piece of close Gauges according to Fig. 101,102,107,108, 110, 112, 109, 113, 104, 111, 105, 114, dynamometer, caliper Figure 2: Standard test finger AC source, measuring instruments Figure 13: Gauges Figure 13: Gauges Figure 19: Test device incl. current source and measuring instruments Figure 15: Test device incl. weights and torquemeter Weights and torquemeter Heating cabinet, current source, measuring instruments Heating cabinet, current source, measuring instruments Current source, measuring instruments Equipment as required by IEC 60309-4 depending on the type of interlock, if any Heating cabinet 1/3 Subcontracting R R R R R R R R R R R S R IEC 60309-2+A1+A2, Ed.4.0 IEC System for Conformity Testing and Certification of Electrotechnical equipment and Components Clause 15.1 15.2 Measurement/testing Contact pressure test Check of withdrawal force 16.101 17.102 18.2 Check of phase inverting means Check of phase inverting means Test of degrees of protection 18.5 19.2 19.3 19.4 20 Humidity treatment Insulation resistance test Electric strenght test Check with gauges Breaking capacity test 21 Normal operation test 22 23.3 Temperature rise test Cord anchorage test 24.1 24.2 Cold treatment Impact test 2013-05-03 Testing / measuring equipment / material needed Gauges according to table 110, dynamometer Test apparatus according to Fig. 115, gauges according to table 111, dynamometer Appropriate test apparatus Appropriate test apparatus Torquemeter Test apparatus acc. IEC 60529: Jointed test finger Rigid sphere 50 mm diameter Rigid sphere 12,5 mm diameter Rigid steel rod 2,5 mm diameter Rigid steel rod 1,0 mm diameter Dust chamber Drip box Drip box -15° Oscillating tube/spray ± 60° or spray nozzle/spray ± 60° Oscillating tube/spray ± 180° Water jet hose nozzle – nozzle 6,3 mm diameter Water jet hose nozzle – nozzle 12,5 mm diameter Immersion tank Humidity chamber Insulation test equipment High voltage test equipment Gauges according to Fig. 104, 109, 111, 113, dynamometer Appropriate test apparatus, power source, adjustable load (resistors and inductors), measuring instruments Appropriate test apparatus, power source, adjustable load (resistors and inductors), measuring instruments AC source, measuring instruments, temperature measuring device Torquemeter, test apparatus according to Fig. 6 incl. weights Apparatus for torque test Refrigerator Figure 7: impact test apparatus 2/3 Subcontracting R R R R R R S R S R R R R S 3PPS S 3PPS S R R R IEC 60309-2+A1+A2, Ed.4.0 IEC System for Conformity Testing and Certification of Electrotechnical equipment and Components Clause 24.3 24.4 24.5 25.1 26.1 27.2 27.3 27.4 27.5 28 29 2013-05-03 Measurement/testing Mechanical strenght test Flexing test Torque test at screwed glands Torque test at screws Creepage distances, clearances Heat treatment Ball-pressure test Glow-wire test Tracking test Corrosion test Short-circuit current withstand test Testing / measuring equipment / material needed Arrangement according to Fig. 8 Apparatus according to Fig. 9 Appropriate test arrangement incl. metal rods Torquemeter Caliper, appropriate gauges Heating cabinet Heating cabinet, test apparatus according to IEC 60695-10-2, caliper Test apparatus according to IEC 60695-2-11 Test apparatus according to IEC 60112 Chemicals, humidity cabinet, heating cabinet Short-circuit testing arrangement according to Fig. 16, 17, 18 incl. appropriate measuring devices 3/3 Subcontracting R R R R R R R R R R S 3PPS IEC 60309-2+A1+A2, Ed.4.0