formulation, development & evaluation of diclofenac sodium tablets

RESEARCH ARTICLE

FORMULATION, DEVELOPMENT & EVALUATION OF DICLOFENAC

SODIUM TABLETS BY USING STARCH PHOSPHATE TO IMPROVE

THE SOLUBILITY

AUTHOR’S:-

Bismi P. Cheriyan

*

, Tarkeshwar Prasad Shukla, Govind Mohan, Shailesh Sharma, Manmohan

Kaushik.

Department of pharmaceutics; NIMS University, Jaipur

Corresponding Author

Ms. Bismi P. Cheriyan

Department of pharmaceutics

NIMS University, Shobha Nagar

Jaipur, Rajasthan (303121)

Email : bismipcherian25@gmail.com

Telephone No: 918290814579

INTRODUCTION:

The solid dispersion technique to improve the dissolution characteristics of poorly water - soluble drugs by the use of water-soluble carriers [1] . Many water –soluble carriers polyethylene glycols, polyvinyl pyrrolidone [2,3] . According to literature review, the starch phosphate is used as carrier in solid-dispersion technique to improve the solubility of the drug. It is also used as disintegrating agent. No reports are available on its use as pharmaceutical excipient.

The objective of the present study is to prepare, characterize and evaluate starch phosphate as a carrier in solid dispersions for enhancing the dissolution rate of diclofenac sodium.

MATERIALS & METHODS:

MATERIALS:

Diclofenac sodium, starch phosphate is prepared in the laboratory, dichloromethane, potato starch, lactose, acacia, talc, magnesium stearate.

PREPARATION OF STARCH PHOSPHATE [4, 5, 6] :

Starch phosphate was prepared based on the method of Choi et al with some modifications. Potato starch (100 g) and di-sodium hydrogen orthophosphate anhydrous

(30 g) were suspended in 100 ml of water and continuously stirred for 20 min. This starch slurry was then filtered and the wet starch mixture was conditioned for 12 h at room temperature

(280C). To enhance phosphorylation, this mixture was heated in a forced air oven at 130°C for 3 h. The product obtained was ground and sized.

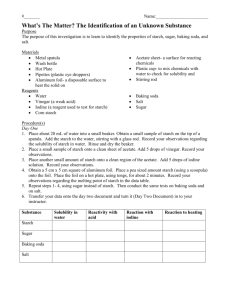

Figure no: 1 reaction on starch & disodium hydrogen O-phosphate

EVALUATION OF STARCH PHOSPHATE [7, 8, 9] :

Characterization of Starch Phosphate

The starch phosphate prepared was evaluated for following

1.

Solubility:

Solubility of starch phosphate was tested in water, aqueous buffers of pH 1.2, 4.5, and 7.4 and organic solvents such as alcohol, dichloromethane, chloroform, acetone and petroleum ether.

2.

pH:

The pH of 1% w/v slurry was measured.

3.

Melting Point:

Melting point was determined by using melting point apparatus.

4.

Viscosity:

Viscosity of 1% dispersion in water was measured using Ostwald Viscometer.

5.

Swelling Index:

Starch phosphate (200 mg) was added to 10 ml of water and light liquid paraffin taken in two different graduated test tubes and mixed. The dispersion in the tubes was allowed to stand for 12h. The volumes of the sediment in the tubes were recorded. The swelling index of the material was calculated as follows.

Volume of sediment in water – Volume

of sediment in light liquid paraffin

×

100

S.I (%) = Volume of sediment in light liqiud Paraffin

6.

Test for gelling property:

The gelling property (gelatinization) of the starch and starch phosphate prepared was evaluated by heating a 7% w/v dispersion of each in water at 100°C for

30 min.

7.

Moisture absorption:

The hygroscopic nature of starch phosphate was evaluated by moisture absorption studies in a closed desiccator at 84% relative humidity and room temperature.

8.

Particle size: Particle size analysis was done by sieving using standard sieves.

9.

Density:

Density (g/cc) was determined by liquid displacement method using benzene as liquid.

10.

Bulk density:

Bulk density (g/cc) was determined by three tap method in a graduated cylinder.

11.

Angle of repose:

Angle of repose was measured by fixed funnel method.

12.

Compressibility index:

Compressibility index (CI) was determined by measuring the initial volume (Vo) and final volume (V) after hundred tapping of a sample of starch phosphate in a measuring cylinder. CI was calculated using equation.

Compressibility index (CI) = Vo – V × 100

Vo

CALIBERATION CURVE :

100 mg of diclofenac sodium was taken in a conical flask & dissolve in 100ml of pH 6.8 phosphate buffer.10 ml of solution was pipette out from above solution & diluted up to 100 ml with pH 6.8 phosphate buffer. Now pipette out 1, 2, 3, 4, & 5ml solution from above solution & dilute up to 10 ml with pH 6.8 phosphate buffer. Measure the absorbance at 283nm by using UV visible spectrophotometer & plot the graph of concentration (µg/ml) versus absorbance.

Table No1: Calibration curve

CONCENTRATION ABSORBANCE

0

10

20

30

40

50

0

0.367

0.595

1.203

1.502

1.900

PREPARATION OF SOLID DISPERSION OF DICLOFENAC SODIUM IN STARCH

PHOSPHATE [10, 11, 12] :

Diclofenac sodium was dissolved in dichloromethane (10ml) in a dry mortar to get a clear solution. Starch phosphate was then added and mixed. The thick slurry was kneaded for 15 min. for complete evaporation of dichloromethane and then dried at 55°C until dry. The dried mass was pulverized and sieved through mesh no. 100.

PREPARATION OF DICLOFENAC SODIUM –SD [13, 14, 15] :

Compressed tablets each containing 50mg of diclofenac sodium were prepared by wet granulation method employing diclofenac sodium alone & its solid dispersion in starch phosphate in the ratio of drug : starch phosphate (1:1), (1:2), (1:3), (2:1). Lactose was used as diluents to adjust weight to 250mg. acacia 2%, talc 2% & magnesium stearate 2% were incorporated respectively as binder & lubricants.

Table no:2 description of trial taken

INGREDIENTS F1(1:1) F2(2:1) F3(1:2) F4(1:3) F5

DICLOFENAC

SODIUM

5Omg 50mg 50mg 50mg 50mg

50mg 25mg 100mg 150mg - STARCH

PHOSPHATE

DICHLOROMETHA

NE

10ml 10ml 10ml 10ml -

137mg 162mg

4.4mg 4.4mg

4.4mg 4.4mg

87mg 37mg 187mg

4.4mg 4.4mg 4.4mg

4.4mg 4.4mg 4.4mg

LACTOSE

ACACIA

MAGNESIUM

STEARATE

TALC

WATER

4.4mg q.s

4.4mg q.s

4.4mg q.s

4.4mg q.s

4.4mg q.s

Disintegration test:

To test for disintegration time, one tablet is placed in each tube and the basket rack is positioned in a 1 litre beaker of water at 37°C+2°C. A standard motor driven device is used to move the basket assembly up and down through a distance of 5 to 6 cm at a frequency of 28 to 32 cycles per minute. When all six tablets have disintegrated, time is noted.

F: IN-VITRO Dissolution test:

Dissolution rate was studied by using USP type II apparatus rotated at 75 rpm, 900 ml of phosphate medium. Temperature of dissolution medium was maintained at 37± 0.5

0 C. Aliquot of dissolution medium was withdrawn at specific time interval and it was filtered. Absorption of filtered solution was checked out by UV spectroscopy at 283 nm & drug content was determined from standard curve, dissolution rate was studied for all designed formulation .

RESULTS:

EVALUATION OF STARCH PHOSPHATE:

The starch phosphate was characterized on the basis of solubility, pH, melting point, viscosity, swelling index, angle of repose, bulk density, tapped density.

Table No:3 Characterization of starch phosphate

Sr.No. Property Result

1.

2.

3.

4.

5.

6.

Solubility

PH (1% w/v aqueous dispersion)

Melting Point

Viscosity (1% w/v aqueous dispersion)

Swelling Index

Gelling Property

Insoluble in all aqueous and organic solvents tested

7.25

Charred at 210 o

C

2.11 cps

400

No gelling and the swollen particles of starch phosphate

7. Moisture Absorption

8.

9.

10.

11.

12.

Particle Size

Density

Bulk Density

Angle of Repose

Compressibility Index

Caliberation curve:

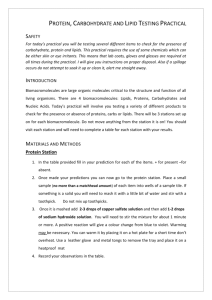

Figure no: 2 caliberation curve

2,5 separated from water.

Whereas in the case of starch, it was gelatinized and formed gel.

< 4.0 %

152 μm (80/120 mesh)

1.667 g/cc

0.534 g/cc

20.040

11.01 %

2 y = 0,0381x + 0,0417

R² = 0,9975

1,5

1 abs

Линейная (abs)

Линейная (abs)

0,5

0

0 20 40 concentration (mcg/ml)

60

Table No: 4 disintegration time formulation Disintegration time (sec.)

F1

F2

F3

F4

82

70

59

52

F5 102

Table no: 5 dissolution profile

F1 F2 F3 F4 TIME

(MIN)

0 0 0 0 0

5 25.6 28.8 38.5 43.8

F5

0

22.2

10

15

20

25

40.9

62.3

73.2

78.9

44.5

65.8

76.7

82.5

62.3

77.5

85.1

91.4

66.7

87.5

94.5

97.5

35.1

55.1

69.9

74.5

30 90.8 91.4 94.5 98.2 87.4

DISCUSSION:

The present work was carried out to formulate and to improve the solubility of diclofenac sodium by using starch phosphate. The flow property of starch phosphate was found to be good.

The flow property depends upon the angle of repose & compressibility index & the value was found to be 20.04

0

& 11.01% respectively.

The dissolution of all batches F1-F4 was compared with F5. F5 does not contain starch phosphate & all other batches contain starch phosphate in different ratio. Among all the batches

F10 shows high % drug release because F10 contain high amount of starch phosphate..According to all parameter of evaluation, batch F4 was optimized one, because it shows high % drug release when compared to other batch within 30 min. & all other parameter was also found to be optimum for F4.

ACKNOWLEDGMENT:

Authors are grateful and thankful to Dr. Balvir S Tomar, Chancellor & Dr. K.C. Singhal, Vice

Chancellor NIMS University, Jaipur for providing necessary facility.

REFERENCES:

1.

Sekiguchi, & Obi, ‘Studies on absorption of eutectic mixture’, Chemical Pharm. Bulletin,

1961,vol. 9, 866-872.

2.

Hirasawa, N., Ishise, S. & Miyata H., ‘An attempt to stabilize Nivaldipine solid dispersion by the use of ternary systems’. Drug Development and Industrial Pharmacy,

2003,vol. 29, 997-1004.

3.

Rawat, S. & Jain, S., ‘Rofecoxib-beta-cyclodextrin inclusion complex for solubility enhancement’, Pharmazie,2003, vol. 58, 639-641.

4.

Chowdary K.P.R.,Entury V.,Pallavi T.V., “Formulation development of etoricoxib tablets by wet granulation & direct compression method employing starch phosphate- A new modified starch, Des pharmacia hetter,2011,3(6),163-172.

5.

Prashanthi N.L., Manikiran S.S., Rao N.R., “Invitro drug release studies of ziprasidone from tablets using natural gums from biosphere”, Arch.Appl.Sci.Res,2011,3(2),513-519.

6.

Vaghela B.J,Kayastha R.R., Bhatt N.M.,Pathak et al “Formulation & evaluation of fast disintegrating tablet of diclofenac sodium”, Int.J.Pharm Res & Dev,2011,3(6), 17-22.

7.

Chowdary k.P.R, Entury V.,Rani A.S.,“Preparation and evaluation of starch phosphate-

A new modified starch as a disintegrant in tablet formulation”

Int.J.Chem.Sci,2011,9(2),889-899.

8.

Pandey V.P.,Reddy K.V.,Amarnath R. “Studies on diluents for formulation of tablets”Int.J.Chem.Sci,2009,7(4),2273-2277.

9.

Prashanthi N.L., Manikiran S.S., Rao N.R., “Invitro drug release studies of ziprasidone from tablets using natural gums from biosphere”, Arch.Appl.Sci.Res,2011,3(2),513-519.

10.

Meiczingen M., Dences J., Marton G., & Dences B. “Investigation of research occurring at starch phosphorylation, American chem. society-2005.

11.

Kumar S. & chowdary K.P.R., “Formulation development of selected antiretroviral drugs by direct compression method”, Int.J.Pharmacy Sci,2012, 4(2), 185-188.

12.

Chowdary K.P.R., Enturi V., “Enhancement of dissolution rate &formulation development of efavirenz tablets employing starch citrate-A new modified starch”, J.

Appl. Pharm Sci, 2011,1(5),119-123.

13.

Chowdary K.P.R., Chandra D.U., Parimala V.,Indira M., “A factorial study on formulation development of ibuprofen tablets employing stach 1500 & PVP K-30” Int. J.

Pharma Sci Res,2012, 3(1),189-193.

14.

Jubril I.,Muazu J. & Moahmmaed G.T. “Effect of phosphate modified & pregelatinized sweet potato starches on disintegrant property of paracetamol tablets formulations”,J.

App. Pharm. Sci.,2012, 2(2),32-36.

15.

Gunn’s and C, “Dispensing for pharmaceutical students”, 12 th

edition,CBS publishers and distributors, 2006,11,188-189.

TABLES:

Table No1: Calibration curve

CONCENTRATION ABSORBANCE

0

10

20

30

40

50

0

0.367

0.595

1.203

1.502

1.900

Table no:2 description of trial taken

INGREDIENTS F1(1:1) F2(2:1) F3(1:2) F4(1:3) F5

5Omg 50mg 50mg 50mg 50mg DICLOFENAC

SODIUM

STARCH 50mg 25mg 100mg 150mg -

PHOSPHATE

DICHLOROMETHA

NE

LACTOSE

ACACIA

MAGNESIUM

STEARATE

TALC

WATER

10ml

137mg

4.4mg

4.4mg

4.4mg q.s

10ml

162mg

4.4mg

4.4mg

4.4mg q.s

10ml

87mg

4.4mg

4.4mg

4.4mg q.s

10ml

37mg

4.4mg

4.4mg

4.4mg q.s

-

187mg

4.4mg

4.4mg

4.4mg q.s

Table No:3 Characterization of starch phosphate

Sr.No. Property Result

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Solubility

PH (1% w/v aqueous dispersion)

Melting Point

Viscosity (1% w/v aqueous dispersion)

Swelling Index

Gelling Property

Moisture Absorption

Particle Size

Density

Bulk Density

Angle of Repose

Compressibility Index

Insoluble in all aqueous and organic solvents tested

7.25

Charred at 210 o

C

2.11 cps

400

No gelling and the swollen particles of starch phosphate separated from water.

Whereas in the case of starch, it was gelatinized and formed gel.

< 4.0 %

152 μm (80/120 mesh)

1.667 g/cc

0.534 g/cc

20.040

11.01 %

Table No: 4 disintegration time formulation Disintegration time (sec.)

82

70

59

52

102 F5

F1

F2

F3

F4

Table no: 5 dissolution profile

TIME

(MIN)

F1 F2

0

5

0

25.6

0

28.8

10

15

40.9

62.3

44.5

65.8

20 73.2 76.7

25 78.9 82.5

30 90.8 91.4

F3

0

38.5

62.3

77.5

85.1

91.4

94.5

F4 F5

0

43.8

66.7

87.5

94.5

97.5

98.2

0

22.2

35.1

55.1

69.9

74.5

87.4

Figures:

Figure no: 1 reaction on starch & disodium hydrogen O-phosphate

2,5

2

1,5

1

0,5 y = 0,0381x + 0,0417

R² = 0,9975

0

0 20 40 concentration (mcg/ml)

Figure no: 2 caliberation curve

60 abs

Линейная (abs)

Линейная (abs)