Ferroelectricity emerging in strained (111)-textured

Supplementary Material for

“Ferroelectricity emerging in strained (111)-textured ZrO

2

thin films”

Zhen Fan

1,a)

, Jinyu Deng

1

, Jingxian Wang

Xiaobing Yan

1

, Zhili Dong

2

2

, Ziyan Liu

1

, Ping Yang

3

, Juanxiu Xiao

, Jingsheng Chen

1

,

, John Wang

1 1,a)

1

Department of Materials Science and Engineering, National University of Singapore, 9

2

Engineering Drive 1, Singapore 117575, Singapore

School of Materials Science and Engineering, Nanyang Technological University,

Nanyang Avenue, Singapore 639798, Singapore

3

Singapore Synchrotron Light Source, National University of Singapore, 5 Research

Link, Singapore 117603, Singapore a) To whom correspondence should be addressed. Electronic addresses: a0082709@u.nus.edu; msecj@nus.edu.sg

1

Approximations made in the model.

In our model of the (111)-ZrO2/(001)-TiN interface, anions and their bonding with cations at the interface and the partial oxidation of TiN are neglected. The bonding between TiN and ZrO

2

is complex and may thus be difficult to be modeled accurately. According to a previous detailed XPS study (W. Weinreich et al.,

Microelectron. Eng. 86, 1826, 2009), at the ZrO

2

/TiN interface, Ti-O and Zr-N bonds can be formed, and excessive O for Ti may lead to oxygen vacancies. The bonding between cations and anions at the ZrO

2

/TiN interface is therefore quite flexible to accommodate the strained lattice of

ZrO

2

. Because anions are light and their bonding with cations is flexible, they are not taken into consideration in our modelling. Then, during sputtering, the TiN can be partially oxidized to

TiO x

N y

. For TiO x

N y

, the cubic lattice is still retained (C. H. Shin et al., J. Solid State Chem. 95,

145, 1991) and even a full oxidization (i.e., the case of TiO) can only cause a small variation in lattice constant of ~1.3% (X. Yang et al. Chem. Phys. Lett. 383, 502, 2004). In this connection,

TiO x

N y

can be approximated as TiN, which can facilitate our modeling. Additionally, we note that the bonding between TiN and ZrO

2

and the partial oxidation of TiN do not significantly influence the interface by forming an intermediate layer with a noticeable thickness or completely modify the orientation of the ZrO

2

layer. This viewpoint can be evidenced by our HRTEM results

(Figure 2(b)), which have revealed the relatively sharp interface between ZrO

2

and TiN and the clear (111) lattice fringes of ZrO

2

even near the interface. Therefore, our model based on the

(111)-ZrO2/(001)-TiN interface is still valid. With regard to the epitaxial relationship, it will be affected by the bonding between TiN and ZrO

2

and the partial oxidation of TiN to some extent.

However, as discussed in the main text, it is unnecessary to require the epitaxial relationship at a macroscopic level. We therefore believe that our model with reasonable approximations, i.e., neglecting the anions and their flexible bonding with cations at the interface and also neglecting the partial oxidation of TiN, is applicable to describing the strain effect on the stabilities of various ZrO

2

phases.

2

P-E results of ZrO

2

films with thicknesses of 8, 18, and 24 nm.

The olive-shaped loops of the

8-nm-thick ZrO

2

film shown in Figure S2(a) are caused by the leakage current. The leaky nature of this film is confirmed by the large current density ( J ) under DC electric fields (Figure S3(a)) and also the large dielectric loss at near-static frequencies (Figure S3(b)). The P-E loops of the

24-nm-thick film are quite confusing (Figure S2(c)). Because the increase of applied field fails to induce distinct ferroelectric loops but inflates the loops significantly, there may be a very small or even zero fraction of the ferroelectric phase in the 24-nm-thick film. The 18-nm-thick film exhibits similar ferroelectric-like behavior as the 12-nm-thick film, but also exhibits a more significant feature of leakage (Figure S2(b)). The weak current peak at negative ~1.9 MV/cm, as shown in Figure S2(d), may indicate the ferroelectricity of the 18-nm-thick film. The disappearance of hysteresis under high fields is also observed in the 18-nm-thick film.

More discussion on the origins of the disappearance of hysteresis. The disappearance of hysteresis after applying a high field is permanent and the hysteresis does not revive when the applied field returns to a lower field. However, the hysteresis can be preserved when the applied field is kept at a lower field and it exhibits a conventional fatigue behavior when the low field cycling is applied (Figure S4). We have excluded the existence of a small conducting path which disappears under a high field, as the origin of the observed disappearance of hysteresis. This is because if the conducting path already exists, it shall be revealed by the dielectric behavior of large loss at the low frequencies. Such dielectric behavior, however, is not observed in 12- and

18-nm-thick films (Figure S3(b)). In addition, the hysteresis will start to appear at the very low field if the conducting path exists, which is not our case (e.g., there is almost no hysteresis for the

12-nm-thick field under the applied field of 0.83 MV/cm). The formation of the conducting path often relies on the abundant oxygen vacancies existing in the ZrO

2

bulk. We have therefore

3

performed XPS studies for Zr 3d and O 1s (Figure S5). There is no remarkable feature of valence changes of Zr and O, indicating that the amount of oxygen vacancies is small. In fact, in the capacitor structure comprising TiN and ZrO

2

, bipolar resistive switching has been reported (B.

Sun et al., J. Appl. Phys. 105, 061630, 2009). In the bipolar switching, the high and low resistance states can be turned on or off reversibly be sweeping the field, which is, however, not our case again. At this stage, we have proposed several plausible reasons for the disappearance of the hysteresis, as detailed in the main text.

4

Figure S1 . HRTEM image showing the TiN/MgO interface. In this thin region, the ZrO

2

layer has been completely removed by ion milling due to the different thinning rates of different layers.

5

Figure S2. P-E hysteresis loops ( f = 3.3 kHz) of ZrO

2

films with thicknesses of (a) 8 nm, (b) 18 nm, and (c) 24 nm. (d) The current response to a voltage stimulation of the 18-nm-thick film.

6

Figure S3 . (a) DC current density-electric field ( J-E ) curves, and (b) dielectric spectra in frequency domain of ZrO

2

films different thicknesses.

7

Figure S4.

Fatigue behavior of the 12-nm-thick ZrO

2

film measured with an applied stress of

2.08 MV/cm.

8

Figure S5.

XPS spectra of the 12-nm-thick ZrO2 film: (a) Zr 3d and (b) O 1s. There is almost no shift of Zr 3d peaks. For example, the binding energy of Zr 3d5/2 is 282.5 eV, which is consistent with the standard value (H. J. M. Bosman et al., Journal of Catalysis, 161, 551, 1996). There is also no obvious additional shoulders of O 1s peak which corresponds to the non-lattice oxygen

(C.-C. Lin et al., Nanoscale Research Letters 7, 187, 2012).

9

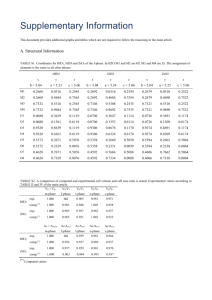

TABLE S1. Parameters reflecting the strain state: tensile/compressive deformation Δ a and shear deformation Δ α .

Structure

C_F

T_P

O_ P

M_P ca2

2

4

1 m-3m

2

/c

1

/mnc

↓ b

↑

↓

↑ a

<1-10> a

(Å) a

<11-2>

(Å)

Δ a

(Å)

3.439+4.066 5.799 1.706

3.958+3.454 6.385 1.804

3.546+3.350 5.910 0.986

3.439+4.066 6.191 1.703

Δ a avg

(Å)

7.241

7.241

7.241

7.198

7.262

7.262

6.271 1.519

6.271 1.519

6.271 1.519

6.308 1.513

6.252 1.521

6.252 1.521

3.529+3.782 6.185 1.503

3.422+3.905 6.400 1.734

3.478+3.735 6.019 1.239

3.529+3.782 6.333 1.651

3.422+3.905 6.117 1.451

3.478+3.735 6.620 1.840

3.958+3.454 5.858 1.277

3.546+3.350 7.293 2.196

1.519

1.492

1.648

1.727

1.519

1.570

1.498

1.613

α

( o )

90

90

90

90

89.6

89.6

88.1

87.8

88.0

88.7

89.5

89.1

85.6

86.8

89.5

82.4

89.4

82.9

Δ α

( o avg

)

0

2.03

0.90

2.70

5.10

0.27

1.47

3.90 a a

[1-10]

, a

[-101]

and a

[01-1]

of each structure are presented from top to bottom in the column of a

<1-10>

.

Correspondingly, a

[11-2]

, a

[1-21]

and a

[-211]

of each structure are presented from top to bottom in the column of a

<11-2>

. b “↓” denotes downward while “↑” denotes upward.

10