ACV-11-06

advertisement

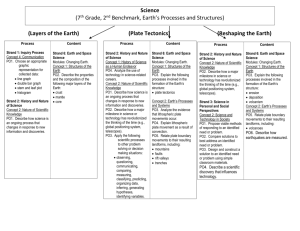

OICA inputs to ACV-11 meeting Results from OICA discussions: OICA considers ACV systems as being an improvement for safety of drivers during coupling operation, which has to be supported by relevant regulations (R13 and R55). We see a need to define a standardized interface for tractor/semi-trailer combinations in R13, in order to ensure compatibility of vehicle equipped with ACV systems in the best way and avoid adding new/complex in-service requirements for drivers. This can be done by referring to ISO 13044 or by extracting relevant technical specifications to add them as an appendix to annex 22. Such a standard is not as crucial on truck/trailer combinations, at least in a short / mid-term, since the coupling process is fully different from tractor / semi-trailer (less risk of mismatch by driver); no standard exist today; there is already one FACS system on the road for several years. Having no standard is acceptable. Double connection (i.e ACV + ISO 7638) has to be permitted by R13, but not required, since: - It may be required for practical reasons but is not strictly necessary to ensure safety - Mandating ISO 7638 in parallel to ACV would only make sense if manual pneumatic and lighting would be mandated as well, why is not relevant in R13. - It may kill the economic interest of ACV, if we have to fit both systems in parallel forever CLEPA comments in document ACV-10-05 - with comments from Clepa.doc are relevant and have to be addressed by the group. OICA have more detailed comments and proposals to document ACV-10-05 (see specific document). What is the intention regarding ACV in R55: define a specific class of coupling with associated standard dimensions and characteristic values? Or only characteristics values and tests? Or? Short pros and cons analysis of having a standardized interface in R13 Pros: - Solves incompatibility issues between of ACV from different brands, which prevent problems in the field and give more flexibility to the fleets owners. Notes: It is assumed here that fulfilment of ISO 13044 guarantees compatibility Potential problems: electric incompatibility not detected in all cases, damaging of ACVs… - Does not multiply sources of incompatibilities (which are already numerous today regarding pneumatic connections, lighting and mechanical coupling) Avoid adding in-service requirements for drivers, with legal and safety implications Avoid adding requirements on manufacturers to define compatibility between ACVs at type approval Cons: - Brake to innovation (despite ISO 7638 did not block ACV) - Risk that the standard is not technically mature and have to be changed later on (despite product maturity is proven) OICA inputs to ACV-11 meeting Misc. comments and questions Is it a desirable situation to have in the future several types of automated connectors from same or different brands that won’t be compatible together, potentially with very similar designs, increasing risks of mistakes for drivers? It looks preferable for drivers / fleet owners to have as much inter-changeability as possible. ISO 7638 did not block ACV/FACS innovation but led regulation and manufacturers experts to meet and consider how these systems could be introduced on the market in a safe way. Having a standardized interface defined in R13 does not mean it is closed to further innovation / new couplings systems. It means such systems would have to be considered with regard to the situation at the time being introduced. OICA inputs to ACV-11 meeting Food for thinking Learning from R13 and R55 R13: - R13 is currently mandating a standard for brake electric interface (ISO 7638) R13 is not mandating a standard for pneumatic couplings No information required about pneumatic couplings compatibility (*) Functionality / performance of electric and pneumatic connections are defined (*) in the field, several standards exist for pneumatic couplings, without need to give info about compatibility. The external shape is enough in itself for driver to know if compatible or not. R55: - R55 is defining classes of couplings Couplings are interchangeable within their class, independent of manufacturer. (note: this is not the case for some classes for specific usages or unique devices to some countries covered by national standards) - For each class, standard dimensions and characteristic values are defined to ensure interchangeability (compatibility) and sufficient performance. Coupling manufacturer is approving his couplings according to the concerned R55 class. Once this is done, compatibility with couplings from the same class is ensured. Vehicle manufacturer is approving the correct installation of the coupling on the vehicle. All mechanical coupling devices or components shall be marked with the class of the device or component R55 is in a way defining the conditions to guarantee that two couplings are compatible together, but is open to new innovating coupling systems like ACV / FACS. Current proposals for ACV ACV-10-05 proposal: - This proposal is following the current R13 way used for pneumatic couplings. - But since compatibility is not visible by driver based on external shape of the ACV, the proposal is adding provisions for giving information about compatibility. - ACV/FACS will be a new class of coupling in R55 but the brake electric and pneumatic part of the ACV in R13 does not follow R55 principle. OICA proposal: - The proposal to standardize the interface follows the current R13 way used with ISO 7638. OICA inputs to ACV-11 meeting Possible way forward, inspired from R13 and R55 If not mandating a standardized interface, R13 should define: - Functionalities of the ACV - Conditions to guarantee that two ACVs are compatible together, through the specification of a standardized interface. (since today, regulation have no grip on ISO standards evolution). - Provisions to make information about compatibility of different ACVs available to end user - A way to support future innovation Proposal (principle only): - Define categories of ACV in R13 (below is only a principle): Automated connectors can be of different categories (footnote 1/) Category A Category B Category C Category D standardized automated connectors for tractor / semi-trailer combination conform to ISO 13044 (or appendix xx of annex 22). All interfaces of category A are compatible together. non standardized automated connectors for tractor / semi-trailer combination, not compatible with category A. Not all interfaces of category B are compatible together. standardized automated connectors for type of combinations other than tractor / semi-trailer. (Footnote 2/) non standardized automated connectors for type of combinations other than tractor / semi-trailer. Not all interfaces of category D are compatible together. standardized automated connectors non standardized automated connectors Tractor/semi-trailer Category A (ISO 13044) Other combinations Category C (no standard yet) Category B Category D Footnote /1: new categories of couplings can be later on added for new / innovative technical solutions, when standard interface will be defined and agreed. Footnote /2 until a standard is defined and agreed, no automated connector shall be defined as of category C. - Requirements: Same functional requirements applies to all categories. Information about the category of the automated connector shall be given at type approval. The driver shall be informed about the compatibility of the automated connector, through marking of the ACV device with the category. Additionally in the case of non-standardized ACV, a specific identification code shall be marked by the manufacturer, for the purpose of defining compatibility with the corresponding male/female part.