Supplementary Information Advanced electrochemical performance

advertisement

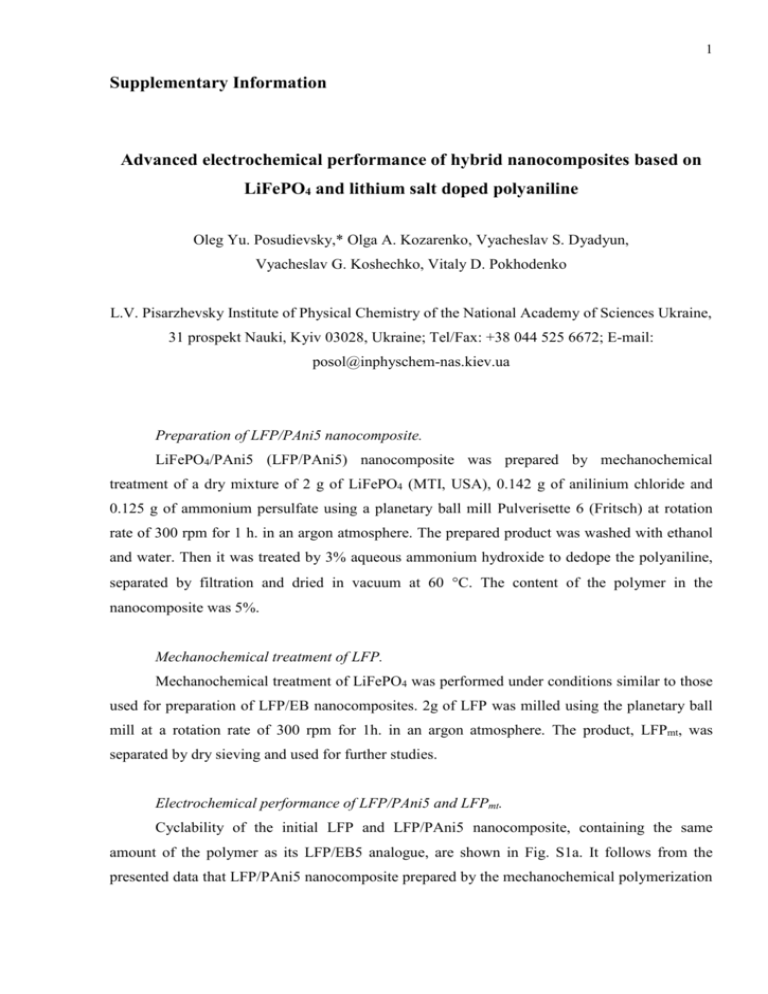

1 Supplementary Information Advanced electrochemical performance of hybrid nanocomposites based on LiFePO4 and lithium salt doped polyaniline Oleg Yu. Posudievsky,* Olga A. Kozarenko, Vyacheslav S. Dyadyun, Vyacheslav G. Koshechko, Vitaly D. Pokhodenko L.V. Pisarzhevsky Institute of Physical Chemistry of the National Academy of Sciences Ukraine, 31 prospekt Nauki, Kyiv 03028, Ukraine; Tel/Fax: +38 044 525 6672; E-mail: posol@inphyschem-nas.kiev.ua Preparation of LFP/PAni5 nanocomposite. LiFePO4/PAni5 (LFP/PAni5) nanocomposite was prepared by mechanochemical treatment of a dry mixture of 2 g of LiFePO4 (MTI, USA), 0.142 g of anilinium chloride and 0.125 g of ammonium persulfate using a planetary ball mill Pulverisette 6 (Fritsch) at rotation rate of 300 rpm for 1 h. in an argon atmosphere. The prepared product was washed with ethanol and water. Then it was treated by 3% aqueous ammonium hydroxide to dedope the polyaniline, separated by filtration and dried in vacuum at 60 C. The content of the polymer in the nanocomposite was 5%. Mechanochemical treatment of LFP. Mechanochemical treatment of LiFePO4 was performed under conditions similar to those used for preparation of LFP/EB nanocomposites. 2g of LFP was milled using the planetary ball mill at a rotation rate of 300 rpm for 1h. in an argon atmosphere. The product, LFPmt, was separated by dry sieving and used for further studies. Electrochemical performance of LFP/PAni5 and LFPmt. Cyclability of the initial LFP and LFP/PAni5 nanocomposite, containing the same amount of the polymer as its LFP/EB5 analogue, are shown in Fig. S1a. It follows from the presented data that LFP/PAni5 nanocomposite prepared by the mechanochemical polymerization 2 is characterized by a sufficiently lower specific capacity and worse cyclability in comparison with the initial LFP (Fig. S1a). 4.4 (a) (b) -1 Discharge capacity (mAh g ) 200 + Potential (V vs. Li/Li ) 160 120 80 LFP LFP/PAni5 40 4.0 3.6 3.2 2.8 LFP LFP/PAni5 2.4 0 0 2 4 6 8 10 12 14 16 18 20 Cycle number 0 20 40 60 80 100 120 140 160 180 -1 Discharge capacity (mAh g ) Figure S1. Cyclability (a) and discharge chronopotentiograms (3d cycle) (b) of the initial LFP and LFP/PAni5 nanocomposite (discharge rate of С/10). It is known that the electrochemical performance of LFP, its specific capacity in particular, is very sensitive to the appearance of defects connected with increase of the oxidation degree of Fe2+ ions up to Fe3+ [32, 33]. So, it could be supposed that the relatively worse characteristics of LFP/PAni5 are connected with partial oxidation of iron ions in LFP due to usage of ammonium persulfate during the mechanochemical polymerization of anilinium chloride and/or the consequence of the post-synthesis treatment of the nanocomposite by ammonium hydroxide for dedoping of PAni. The discharge curve, presented in Fig. S1b, show the feasibility of this supposition, because the form of the chronopotentiogram of LFP/PAni5 is typical for the over-oxidized samples of LFP [33]. ) 180 (b) 160 1 120 -1 140 120 2 100 100 80 60 0 5 10 15 Cycle number 20 Capacity (mAh g 140 25 (c) 160 -1 ) 160 Capacity (mAh g -1 Discharge capacity (mAh g 180 (a) ) 180 1 2 80 60 C/10 С/8 С/5 С/3 Discharge rate 1С 2С 140 120 100 1 2 80 60 40 С/10 С/8 С/5 С/3 Discharge rate 1С 2С Figure S2. Cyclability (charge/discharge rate of C/5) (a), discharge rate dependence of the discharge capacity at the fixed charge rate of C/10 (b) and equal rates of charge and discharge (c) for the initial LFP (1) and LFPmt (2). One of the reasons for the deterioration of the electrochemical properties of LFP after mechanochemical treatment could be the appearance of various defects in its structure, which, as known [S1, S2], adversely affect its electrochemical performance (Fig. S2). So, the fact of the 3 advanced electrochemical performance of the LFP/EB nanocomposites could be due to the ability of the polymer to be a "shock absorber" at mechanical impacts during the mechnochemical treatment, which minimizes their negative effect on the structure of LFP. Table S1. Parameters used for fitting impedance spectra of LFP. Parameter Re, Ω cm2 4.0 3.4 6.2 6.1 Q, sn/( Ω cm2) 4.7E-5 5.05E-5 ZCPEdl n 0.75 0.74 Rсt, Ω cm2 51.3 55.4 Q, sn/( Ω cm2) – 0.007 n – 0.83 Rgb, Ω cm2 – 20.9 RW, Ω cm2 26.9 – ω0, rad/sec 0.14 – n 0.45 – – 0.04 – 0.47 1.8E-4 1.0E-4 ZCPEgb ZW Potential, V ZCPEdiff Q, sn/( Ω cm2) n χ2 Table S2. Parameters used for fitting impedance spectra of LFP/EB15. Parameter Re, Ω cm2 Potential, V 4.0 3.4 4.0 4.1 ZCPEEB Q, sn/( Ω cm2) 7.57E-5 1.58E-4 n 0.73 0.655 4 ZW REB, Ω cm2 14.4 24.1 Cdl, F/cm2 2.5E-5 1.9E-5 Rct, Ω cm2 17.3 23.9 RW, Ω cm2 65.84 – ω0, rad/sec 2.44 – n 0.34 – – 0.034 – 0.27 1.9E-4 9.6E-5 ZCPEdiff Q, sn/( Ω cm2) n χ2 References [S1] Yuan L-X, Wang Z-H, Zhang W-X, Hu X-L, Chen J-T, Huang Y-H, Goodenough JB (2011) Development and challenges of LiFePO4 cathode material for lithium-ion batteries. Energy Environ Sci 4:269–284 [S2] Wang J, Sun X (2012) Understanding and recent development of carbon coating on LiFePO4 cathode materials for lithium-ion batteries. Energy Environ Sci 5:5163–5185