Little Patuxent WRP 6th Addition

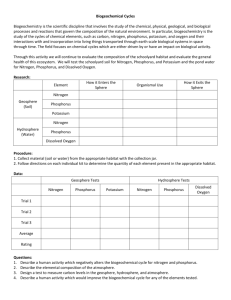

advertisement

Client Name | PROJECT NAME Little Patuxent Water Reclamation Plant Howard County, Maryland Black & Veatch completed two important project assignments for the Howard County Bureau of Utilities. These assignments include an engineering study to improve the performance and reliability of the Little Patuxent Water Reclamation Plant’s existing BNR treatment process and design and construction management services for a major plant capacity expansion and treatment process modifications. Project Elements Optimization of biological nitrogen and phosphorus removal Demonstration testing of advanced BNR process technology Upgrading solids processing to Class A biosolids stabilization Overall treatment plant optimization Capacity Expansion Services Winter Capacity Restoration Study The 18 mgd Little Patuxent Water Reclamation Plant was designed for year round nitrification and biological nutrient removal. Treatment goals were 8 mg/L total nitrogen on an annual average basis and 1 mg/L total phosphorus on a monthly basis. Because of poor activated sludge settling characteristics, the plant could not achieve high enough mixed liquor solids concentrations or long enough solids retention times to maintain complete nitrification at rated treatment capacity during cold winter months. In addition, unexplained effluent phosphorus concentration spikes occurred intermittently throughout the year. Engineering Studies, Design and Construction Management Services Key Team Members Mike Hanna Bob Rectanus Period of Service November 1997 to January 2005 Cost See end of document Client Reference Mr. Don Campbell, P.E. 8900 Greenwood Place Savage, MD 20763 (410) 313-1438 dfcampbell@howardcounty md.gov The objectives of this study were to evaluate process modifications and control strategies to restore winter treatment capacity and improve the reliability of biological phosphorus removal. The study was divided into two phases. Phase 1 reviewed existing process performance and process control to identify performance problems and develop alternative solutions. Phase 2 involved demonstration scale testing of process modifications and process control techniques to evaluate effectiveness. Based on the results of the study, an interim solution involving periodic chlorination of return activated sludge was initiated to control filamentous organism dominance. Process reactor configuration changes and flow distribution improvements were recommended as part of the long term improvements to maximize the capacity and nutrient removal capabilities of the existing biological reactor basins. Little Patuxent Water Reclamation Plant Sixth Addition Black & Veatch designed the Sixth Addition Improvements for the Little Patuxent Water Reclamation Plant. The project included a comprehensive evaluation of treatment process alternatives for expanding treatment capacity from 18 mgd to 25 mgd, improving nitrogen removal performance of existing biological treatment facilities, and complete renovation of solids processing BLACK & VEATCH | Little Patuxent Water Reclamation Plant 1 Client Name | PROJECT NAME facilities. A Project Development Report, prepared as part of the preliminary facilities design evaluation, included plant scale demonstration testing of proposed BNR process reactor modifications and primary sludge fermentation. The fermenters were proposed for supplementing volatile fatty acid production for improving biological phosphorus removal and providing readily degradable carbonaceous BOD needed for higher levels of denitrification. The demonstration testing confirmed the ability of the process modifications to achieve consistent biological phosphorus removal to less than 0.5 mg/L and total nitrogen concentrations below 6 mg/L. The project included demolition of an existing electrical substation, existing sludge drying beds, and part of an existing aerobic digester basin. The Project Development Study - Recommended dividing the Sixth Addition construction work into six separate construction contracts to minimize the impact of construction on existing plant operation and treatment performance during construction. In addition to the preliminary engineering and project planning services provided for preparation of the Project Development Report, Black & Veatch provided detailed design for each of the six construction contracts and overall construction management services for major equipment procurement, construction contract administration, submittal review, construction inspection, and process start-up assistance. The scope and features of each of the six construction contracts included: Contract 1: BNR Capacity Expansion - Added three new biological treatment process reactors configured for enhanced biological nitrogen and phosphorus removal, three new final clarifiers, a new blower building, a new activated sludge pumping station, two new anaerobic fermenter basins for primary sludge, and odor control system for the anaerobic fermenters. The new biological nutrient removal process was designed to utilize readily degradable soluble BOD and volatile fatty acids produced in the anaerobic fermenters for optimizing nitrogen and phosphorus removal. Contract 2: Solids Processing Facilities - Improvements to the plant solids processing facilities included renovation of two existing primary sludge gravity thickeners, renovation of two existing DAF thickeners for waste activated sludge, addition of a third DAF thickener, replacement of existing belt filter presses with two new high solids centrifuges for sludge dewatering, replacement of an existing lime stabilization system with a new lime pasteurization system to produce Class A stabilized biosolids, new lime feed and storage facilities, and new polymer feed and storage facilities. Contract 3: Preliminary and Primary Treatment Improvements - The existing plant headworks facilities and raw wastewater pumping station were renovated to improve raw wastewater screening and pumping efficiency. BLACK & VEATCH | Little Patuxent Water Reclamation Plant 2 Client Name | PROJECT NAME Three existing “climber” type bar screens were rebuilt to reduce the clear opening between bars from ¾-inch to 5/8-inch to capture more of the plastics and stringy material that were contaminating plant sludge and causing problems with sludge pump maintenance. The improvements included the addition of a new Auxiliary Raw Wastewater Pumping Station to increase raw wastewater pumping capacity, a new scum concentrator for handling primary clarifier scum, a new primary clarifier for additional primary treatment capacity, and new primary sludge and scum pumps. Contract 4: Existing BNR Treatment Process Improvements - Eight existing biological process reactors were reconfigured to improve the performance of nitrogen and phosphorus removal. The Improvements included new internal recycle pumps, fermenter VFA liquor addition, new automatic flow distribution gates and changes to internal partition walls. Modifications were also made to four existing final clarifiers and the addition of new plant effluent flow metering. Contract 5: Laboratory Renovations - The existing plant analytical and process control laboratory was completely redone to support process control and water quality monitoring requirements for the treatment plant. New laboratory equipment included nutrient auto-analyzers, new fume hoods and new solids analysis equipment. Contract 6: Plant Control System Upgrades - The existing Foxboro Distributed Plant Control System was upgraded with new process monitoring and control stations located throughout the plant and expanded I/O capability to support the expanded treatment plant capacity. Additional data management functions were added to the plant control system and a new Laboratory Information Management System (LIMS) was added. BLACK & VEATCH | Little Patuxent Water Reclamation Plant 3 Client Name | PROJECT NAME Services: Contract Amount: Final: Engineering Design $3,590,813 $3,729,000 Notes: Preliminary Engineering Study and detailed design for 6 Construction and 2 procurement contracts - Reason for higher final cost: project broken up into 6 separate construction bid packages and 2 equipment procurement packages Services: Contract Amount: Final: Construction Management $4,590,760 $5,951,000 Notes: Construction phase services including 4 full-time field staff - Reason for higher final cost: Owner initiated major re-design changes after receipt of bid; Construction contract time extension Services: Contract Amount: Construction Cost $48,000,000 (Original Engineering Estimate of Construction Cost) $46,351,000 (Final Construction Cost) Total of 6 construction & two procurement contracts Bid Award $43,905,000 Final: Notes: Services: Final Brief Summary of the Results of the Project: The 6th Addition included 7 mgd in capacity expansion and modifications to biological nitrogen and phosphorus removal processes for the entire plant. Phosphorus removal was improved from unstable performance with effluent phosphorus varying from 1 - 3 mg/L to stable performance with effluent phosphorus consistently <0.5 mg/L with no chemical addition. Nitrogen removal was improved from effluent Total Nitrogen of 8 mg/L to less than 5.5 mg/L. BLACK & VEATCH | Little Patuxent Water Reclamation Plant 4