P0482/15A - Northern Ireland Environment Agency

advertisement

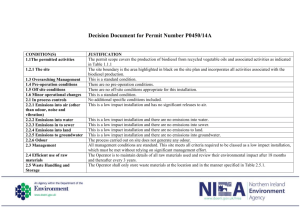

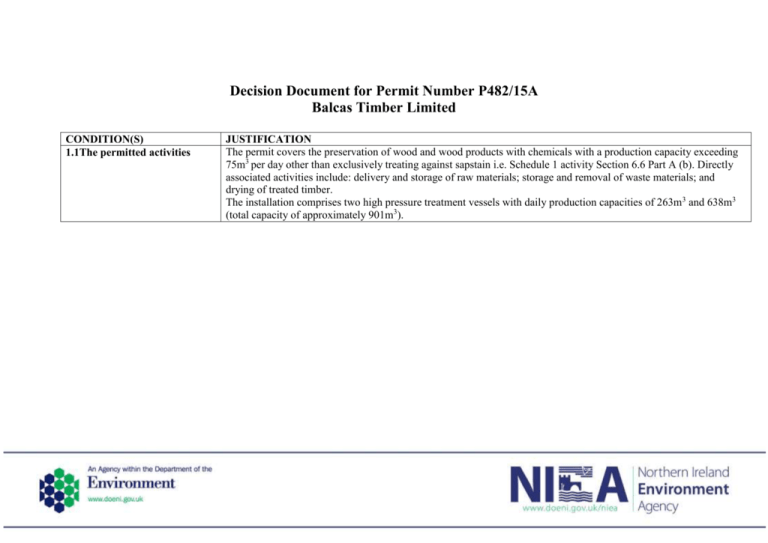

Decision Document for Permit Number P482/15A Balcas Timber Limited CONDITION(S) 1.1The permitted activities JUSTIFICATION The permit covers the preservation of wood and wood products with chemicals with a production capacity exceeding 75m3 per day other than exclusively treating against sapstain i.e. Schedule 1 activity Section 6.6 Part A (b). Directly associated activities include: delivery and storage of raw materials; storage and removal of waste materials; and drying of treated timber. The installation comprises two high pressure treatment vessels with daily production capacities of 263m3 and 638m3 (total capacity of approximately 901m3). Decision Document Part A 1.2.1 The site 1.3 Overarching Management Page 2 of 7 Q57/15 Version 1 Large parts of the site were used as an airbase by the RAF during WWII and subsequently by the army from the 1980s to approximately 1997. Timber processing activities first began at the Balcas Timber Limited site in 1962 and new buildings have been constructed over time. Timber treatment activity is carried on in two areas of the site. The installation boundary is shown in red on the site plan. Directly associated activities include: delivery and storage of raw materials; storage and removal of waste materials; and drying of treated timber. The baseline survey stated that there was no physical evidence (odour or visual) of significant contamination encountered in the soil or water samples collected at the site however the following was detected: Elevated arsenic concentrations from soil samples at BH-105 (Treatment plant 1) however they were below the Generic Assessment Criteria (GAC). Elevated chromium III concentrations from soil samples at BH-105 (Treatment plant 1) however they were below the GAC. Elevated arsenic concentrations were detected in the perched groundwater samples collected from BH-105 (Treatment plant 1) (4.89mg/l) and MW-103 (Treatment plant 2) (0.0139mg/l) and these exceed the GAC concentration of 0.01mg/l. Elevated total chromium (0.9152mg/l) and chromium VI (1.024mg/l) concentrations were detected in the perched water grab sample collected from BH-105 105 (Treatment plant 1) and exceeded the GACs of 0.05mg/l and 0.034mg/l. Elevated copper concentration of 0.086mg/l detected in the perched groundwater sample collected from BH-105 105 (Treatment plant 1) does not exceed the GAC of 2.0mg/l. Elevated arsenic (0.0173mg/l) and boron (1.432mg/l) concentrations were also detected in the groundwater sample which was taken from the tap located in Tanalith building 1. It is understood that this water is supplied from the Pallet Mill well. (It should be noted that the baseline report states that BH-105 at Treatment plant 1 is located in the area of the tracks of the previous treatment facility.) IMP 6.8 has been included to determine if the current preservative could be the source of the contamination. The results of the baseline survey have been passed to the Contaminated Land section of the NIEA Waste Management Unit for information. This is a standard condition. Decision Document Part A 1.4 Pre-operation conditions 1.5 Off site conditions 1.6 Minor operational changes 2.1 In process controls 2.2.1 Emissions into air (other than odour, noise and vibration) 2.2.2 Emissions into water 2.2.3 Emissions in to sewer 2.2.4 Emissions into land 2.2.5 Emissions to groundwater 2.2.6 Odour 2.3 Management Page 3 of 7 Q57/15 Version 1 There are no pre-operating conditions included as the site has been treating timber since the tannalith building no 1 was constructed in 1991 and the tannalith building no 2 was constructed in 2009. The “preservation of wood and wood products with chemicals with production capacity exceeding 75m3 per day other than exclusively treating against sapstain” was included as a new prescribed IED activity in the PPC (IE) Regulations (NI) 2013. There are no off site conditions. These are standard conditions. 2.1.1 and 2.1.2 are standard conditions. The installation uses electricity, therefore no liquid or solid fuels are held at the treatment activity and no Fluorinated gases or Ozone depleting substances are used. There are no specific point source emissions. However, fugitive emissions may occur therefore 2.2.1.1 has been added requiring the operator to use BAT to prevent or where that is not practicable to reduce fugitive emissions to air from the permitted installation. The treatment process is a closed system and therefore the risk of emissions during normal operation is low. There are rainwater emissions from the roof of Plant 1 however there is no pathway for the preservative to reach the roof and therefore no direct monitoring of emissions to water is considered necessary. A separate discharge consent is in place (issued by NIEA WMU consent number 1739/14/1, file number TC 099/14) for emissions to the Drumgay River. This will be subject to ongoing compliance monitoring by the NIEA WMU. Plant 2 harvests the roof rainwater and therefore has no emissions to water. The rainwater harvesting tank has no overflow i.e. is completely sealed. Unused/unabsorbed preservative is recycled for reuse within the treatment system. The site also extracts form boreholes to satisfy the demand for make up water. The areas used for the transfer of and drying of treated material are adequately bunded. Conditions 2.2.2.1 & 2.2.2.2 require the Operator to use BAT to prevent or reduce fugitive emissions to water. There are no waste water emissions to sewer from the treatment process so standard conditions are included. Standard conditions are included as there are no process emissions to land. Standard conditions are included as there are no process emissions to groundwater. This process is not expected to give rise to significant odours therefore standard BAT conditions relating to the control of on-site odour have been included. Standard conditions for the training of staff, maintenance of equipment and procedure for incidents. IMP 6.1 requires written procedures for the transfer of raw materials, process and waste liquids to demonstrate Decision Document Part A Q57/15 Version 1 compliance with condition 2.3.3 to be submitted to the NIEA. IMP 6.2 requires a training plan to be submitted to the NIEA. Conditions 2.4.1 to 2.4.3 are standard conditions for the efficient use of raw materials, water and waste minimisation. 2.4 Efficient use of raw materials Conditions 2.5.1 and 2.5.2 are standard conditions for the storage of waste on site. 2.5 Waste Handling and Storage 2.6 Waste recovery and disposal Conditions 2.6.1 -2.6.3 are standard conditions for the management and recording of waste sent for recovery/disposal from and on site. Condition 2.7.1 and 2.7.2 are standard conditions for the management of energy on site. 2.7 Energy Efficiency Condition 2.8.1 is a standard condition for a plan to prevent and control accidents on site. 2.8 Accident prevention and Condition 2.8.2 requires that the operator shall immediately take measures to limit environmental consequences control following an accident. The condition also specifies that any release of timber treatment chemical should be considered as an accident. IMP 6.3 requires the accident management plan to be amended as the version submitted with the application did not include movement of the tanker between the site gate and the installation nor address the tanker parking and unloading on unmade ground. Conditions 2.9.1 and 2.9.2 are standard conditions for the control of noise. The process contains low powered motors 2.9 Noise and vibration and pumps which are considered unlikely to generate significant noise. There have been previous noise complaints from the site however the sources are other areas of the site (i.e. mills and CHP plant) which are not included as activities within the boundaries of the permit. There are no point source emissions to air, water or sewer from the installation. Other monitoring will be required 2.10 Monitoring such as the integrity of the bunds and the soil and groundwater monitoring therefore conditions 2.10.1, 2.10.2 and 2.10.3 have been included. Conditions 2.11.1 to 2.11.4 are standard conditions requiring a closure plan and notification of closure. 2.11 Closure and Decommissioning This is a single operator site. 2.12 Multi Operator installations There are no transfers to an effluent treatment plant. 2.13 Transfer to effluent treatment plant Page 4 of 7 Decision Document Part A IMPROVEMENT PROGRAMME CONSULTEE COMMENTS Public Health Agency (PHA) District Council Food Standards Agency (FSA) Page 5 of 7 Q57/15 Version 1 IMP 6.1 The operator shall put procedures in place for the transfer of raw, process, and waste liquids as this is an area of risk. IMP 6.2 The Operator shall provide a copy of the training plan to demonstrate compliance with Condition 2.3.4. IMP 6.3 The Operator shall provide an amended accident management plan in accordance with Horizontal Guidance Note H1 section 3.7 i.e. to include the bulk delivery of preservative to the plants. IMP 6.4 The Operator shall provide an accurate site drainage diagram of the current on site arrangements as the one submitted in the application is a drainage improvement scheme and contains proposed measures. IMP 6.5 The Operator shall implement a programme for the protection of ground and groundwater to ensure that risks are monitored. IMP 6.6 The Operator shall review the bunding and containment at the installation, in particular the bulk delivery of preservative as this is currently unmade ground at both plants, and provide an improvement programme to ensure compliance with conditions 2.2.4.2, 2.2.5.1 and 2.2.5.2 with associated timescales to the Chief Inspector. Preservative is delivered in concentrated form and any spill or leak in this area will have the potential to contaminate ground and groundwater. IMP 6.7 The Operator shall provide a copy of the procedures and training records associated with the techniques used to prevent carryover of wood preservative outside the installation boundary. From the photographs provided in the application there is runoff of preservative across the floor of the drying building which could potentially be carried out of the installation on the FLT wheel to the unmade ground outside. IMP 6.8 Due to the substances detected in the baseline survey the Operator is requested to carry out an assessment of the substances detected in the baseline report against the chemicals currently used by the site to determine if the current wood preservative would potentially be the source, and provide a report to the Chief Inspector. Comments and measures in permit where applicable The PHA response stated that they had no immediate concerns. No additional conditions considered necessary. Balcas Timber Limited hold a Part C permit (reference P/12C/023) with the Fermanagh and Omagh District Council for the sawing, drilling, sanding, shaping, turning, planning, curing or chemical treatment of wood. Their response states that there does not appear to be any relevant matters at this time causing concern. No additional conditions considered necessary. The FSA response stated that, based on the information available, provided that the applicant operates and complies with the IED requirements, it is unlikely that there will be unacceptable effects on the human food chain. Decision Document Part A Others (Water management unit) IMPACTS ON THE ENVIRONMENT European sites Q57/15 Version 1 Balcas Timber Limited has a number of discharges for the site which are consented by WMU under the Water (Northern Ireland) Order 1999 (including consent number 1739/14/1, file number TC 099/14 through which rainwater discharges from treatment plant 1 are consented). No samples have been taken by WMU due to lack of access and egress to the discharge point. The NIEA-WMU response states that effective mitigation measures must be in place. IMP 6.4 requires provision of an accurate site drainage diagram. IMP 6.6 requires a review of the effectiveness of the containment and bunding on the installation. No additional conditions considered necessary. Impacts from the installation are not considered significant on any designated habitats as there are no emissions to air or water. There are no pathways for emissions (e.g. treatment chemicals) from the site to the habitats. Please see list of designated sites below. The impact of the installation on the following Europeans sites was considered: Fardrum and Roosky Turloughs SAC (approx 4.7 Km from the installation) and Fardrum and Roosky Turloughs Ramsar (approx 4.7 Km from the installation). Habitats Regulations Assessment In accordance with Regulation 43(1) of the Conservation (Natural Habitats, etc.) (Northern Ireland) Regulations 1995 (as amended), the Chief Inspector (i.e. Competent Authority) has considered whether the application (reference: P0482/15A) either alone or in combination (neither being directly connected with, nor necessary to the management of the site) is likely to have a significant effect on the Natura 2000 site. As part of that consideration, the Chief Inspector has:(a) Taken into account the mitigation measures contained in the application, along with all legally enforceable obligations designed to avoid environmental effects; (b) Applied the precautionary approach set out in the European Commission Guidance “Managing Natura 2000 sites” and as required by the European Court of Justice in C-127/02 (Waddenzee); and (c) Consulted the Natural Environment Division of NIEA and have regard to any representations made by it within such reasonable time as the Chief Inspector may specify for the purposes of the assessment or determining whether an assessment is required for a plan or project. Having carried out a ‘screening’ assessment of the project, the Chief Inspector has concluded that the project would Page 6 of 7 Decision Document Part A ASSIs Other environmental receptors People Overall BAT demonstration Q57/15 Version 1 not be likely to have a significant effect on any European site, either alone or in combination with any other plans or projects. The impact of the installation on the following ASSIs was considered: Devenish Island (ASSI 269) (approx 2.2 Km from the installation), Paris Island Big (ASSI 282) (approx 3.6 Km from the installation), Banagher (ASSI 252) (approx 4.1 Km from the installation), Horse Island (ASSI 040) (approx 4.7 Km from the installation) and Fardrum and Roosky Turloughs (ASSI 138) (approx 4.7 Km from the installation). Impacts from the installation are not considered significant on any designated habitats as there are no emissions to air or water. There are no pathways for emissions (e.g. treatment chemicals) from the site to the habitats. Lower Lough Erne (not a designated habitat) is located approximately 1.2 Kms from the installation. However impacts from the installation are not considered significant as there are no emissions to air, water or land from the installation and no pathways for emissions to the habitat. The nearest housing is located approx 240 meters away from Plant 1 and 330 meters away from Plant 2. Between Plant 1 and the housing there are fields. Between Plant 2 and the housing there is an engineering facility. Significant noise and odour should not be detected at these properties if the process is properly controlled and the conditions of the permit are adhered to. The application and additional information submitted indicates that appropriate measures have been taken to control the risk of pollution of waterways and that procedures are in place for the control of the handling/storage of waste materials on the site. The site is designed with a good level of containment (subject to IMP 6.6). The installation is not a major energy user and is not likely to give reasonable cause for annoyance due to noise. The combination of measures proposed in the application and required by the permit is considered to represent the Best Available Techniques for an installation of this nature. The determination of this application (P0482/15A) is that a permit should be granted. Completed by Industrial Pollution and Radiochemical Inspectorate Date 04th August 2015 Page 7 of 7