View

advertisement

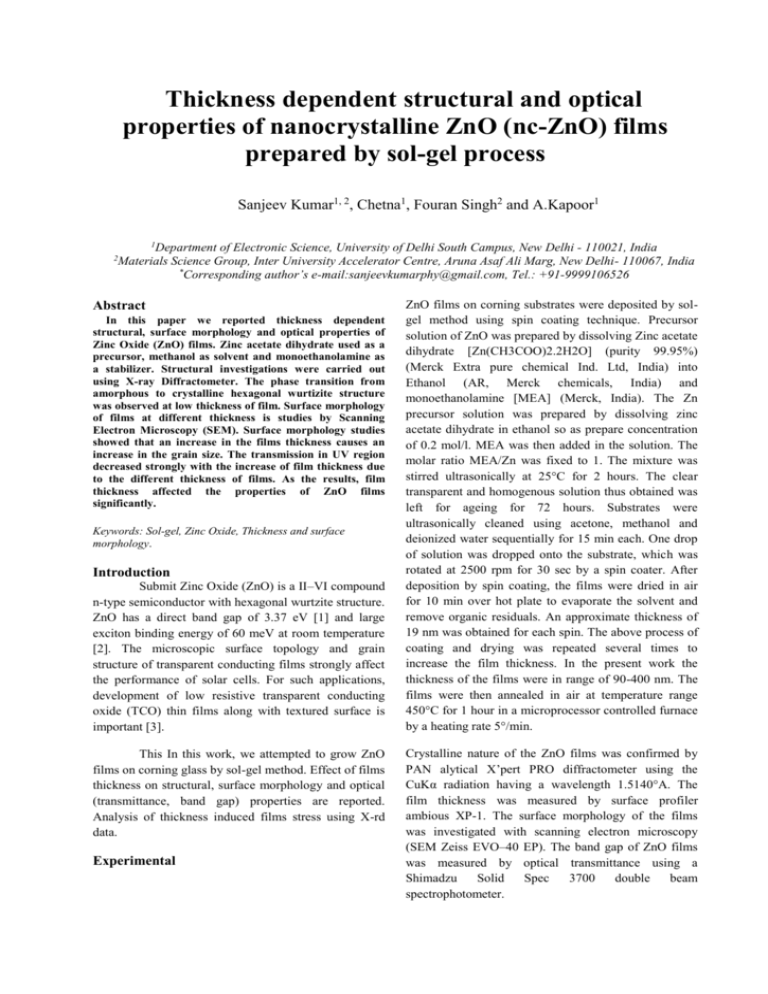

Thickness dependent structural and optical properties of nanocrystalline ZnO (nc-ZnO) films prepared by sol-gel process Sanjeev Kumar1, 2, Chetna1, Fouran Singh2 and A.Kapoor1 1 2 Department of Electronic Science, University of Delhi South Campus, New Delhi - 110021, India Materials Science Group, Inter University Accelerator Centre, Aruna Asaf Ali Marg, New Delhi- 110067, India * Corresponding author’s e-mail:sanjeevkumarphy@gmail.com, Tel.: +91-9999106526 Abstract In this paper we reported thickness dependent structural, surface morphology and optical properties of Zinc Oxide (ZnO) films. Zinc acetate dihydrate used as a precursor, methanol as solvent and monoethanolamine as a stabilizer. Structural investigations were carried out using X-ray Diffractometer. The phase transition from amorphous to crystalline hexagonal wurtizite structure was observed at low thickness of film. Surface morphology of films at different thickness is studies by Scanning Electron Microscopy (SEM). Surface morphology studies showed that an increase in the films thickness causes an increase in the grain size. The transmission in UV region decreased strongly with the increase of film thickness due to the different thickness of films. As the results, film thickness affected the properties of ZnO films significantly. Keywords: Sol-gel, Zinc Oxide, Thickness and surface morphology. Introduction Submit Zinc Oxide (ZnO) is a II–VI compound n-type semiconductor with hexagonal wurtzite structure. ZnO has a direct band gap of 3.37 eV [1] and large exciton binding energy of 60 meV at room temperature [2]. The microscopic surface topology and grain structure of transparent conducting films strongly affect the performance of solar cells. For such applications, development of low resistive transparent conducting oxide (TCO) thin films along with textured surface is important [3]. This In this work, we attempted to grow ZnO films on corning glass by sol-gel method. Effect of films thickness on structural, surface morphology and optical (transmittance, band gap) properties are reported. Analysis of thickness induced films stress using X-rd data. Experimental ZnO films on corning substrates were deposited by solgel method using spin coating technique. Precursor solution of ZnO was prepared by dissolving Zinc acetate dihydrate [Zn(CH3COO)2.2H2O] (purity 99.95%) (Merck Extra pure chemical Ind. Ltd, India) into Ethanol (AR, Merck chemicals, India) and monoethanolamine [MEA] (Merck, India). The Zn precursor solution was prepared by dissolving zinc acetate dihydrate in ethanol so as prepare concentration of 0.2 mol/l. MEA was then added in the solution. The molar ratio MEA/Zn was fixed to 1. The mixture was stirred ultrasonically at 25°C for 2 hours. The clear transparent and homogenous solution thus obtained was left for ageing for 72 hours. Substrates were ultrasonically cleaned using acetone, methanol and deionized water sequentially for 15 min each. One drop of solution was dropped onto the substrate, which was rotated at 2500 rpm for 30 sec by a spin coater. After deposition by spin coating, the films were dried in air for 10 min over hot plate to evaporate the solvent and remove organic residuals. An approximate thickness of 19 nm was obtained for each spin. The above process of coating and drying was repeated several times to increase the film thickness. In the present work the thickness of the films were in range of 90-400 nm. The films were then annealed in air at temperature range 450°C for 1 hour in a microprocessor controlled furnace by a heating rate 5°/min. Crystalline nature of the ZnO films was confirmed by PAN alytical X’pert PRO diffractometer using the CuKα radiation having a wavelength 1.5140°A. The film thickness was measured by surface profiler ambious XP-1. The surface morphology of the films was investigated with scanning electron microscopy (SEM Zeiss EVO–40 EP). The band gap of ZnO films was measured by optical transmittance using a Shimadzu Solid Spec 3700 double beam spectrophotometer. 10 100 Results and discussion 1.6x10 (b) (h )2 (cm -1 eV)2 80 60 98 nm 40 20 180 nm 366 nm 10 1.2x10 98 nm 180 nm 280 nm 366 nm 9 8.0x10 9 4.0x10 280 nm 0 300 400 500 600 700 0.0 3.1 800 3.2 Wave le ngth (nm) 3.3 h(eV) 3.4 3.34 (c) 3.32 Band gap (eV) Fig. 1 shows the thickness of the ZnO film as a function of the number of deposition cycles. The film thickness increased linearly with increase the number of cycles, representing a typical characteristic of the sol.gel technique. It is interesting to see that the linearity of the thickness change is observed. The XRD and SEM investigations give the information about the structure of film. The preferred orientation of grains, grain size, stress, strain, etc can be obtained from the analysis of the width, intensity and position of X-rd peaks. Trans mittanc e (%) (a) 3.30 3.28 3.26 3.24 3.22 100 The crystallites sizes as determined from the value of FWHM were calculated using Scherer’s formula 0.94 D B cos (1) Where, λ, θ and B are the X-ray wavelength, Bragg’s diffraction angle and FWHM of the ZnO (002) diffraction peak, respectively. No crystals have been obtained at low thickness because film has shown amorphous nature. The crystal size decrease with increase in the film thickness up to 289 nm after that it is increase. Thickness of film (nm) 400 350 300 250 150 200 250 300 350 400 Thicknes s of film (nm) Fig.2 Effect of film thickness on (a) Transmittance in the wavelength range 300-800 nm for ZnO films. (b) Band gap calculation for ZnO films using Tauc’s plot. (c) Band gap variation of ZnO films. Transmittance measurements were carried out in 300800 nm range of spectrum. The effect of film thickness on the optical properties such as transmittance and band gap of ZnO films is investigated. Figure 5 shows the transmittance curves of ZnO films with thickness (92642 nm). All the samples showed high and constant transparency higher than 84% in the visible range (300– 800 nm). Maximum transmittance was found to be 88% for 280 nm thick film and the minimum transmittance was found to be ~ 85% for 366 nm thick films as shown in Fig. 2. The transmittance remains constant for all the samples, in this range of spectra. Conclusion 200 150 100 4 6 8 10 12 14 16 18 20 22 Number of deposition cycles Fig. 1 Graph between thickness of film Vs number of deposition cycles. Fig.2 shows the Tauc’s plot for optical band gap as a function of film thickness for the ZnO films. The band gap was observed to decrease from 3.33 to 3.24 eV as the film thickness increase from 98 to 280 nm. Beyond this thickness (366 nm), increase in the band gap is observed to be 3.25 eV. High quality transparent ZnO films were deposited with different thickness by sol.gel method using spin coating technique. The quality and the growth pattern of the film are controlled by its thickness. Minimum stress has been obtained at film thickness 280 nm. Highly c-axis oriented crystalline films with an average transmittance of 88 % were obtained for a film thickness of 280 nm. Band gap is dependent on thickness induced stress of films References: [1] K. Nakahara, H. Takasu, P. Fons, A. Yamada, K. Iwata, K. Matsubara, R. Hunger, S. Niki, Appl. Phys. Lett. 79 (2001) 4139. [2] J. Chen, T. Fujita, Jap. J. Appl. Phys. 42 (2003) 602. [3] H. Schade and Z. E. Smith, J. Appl. Phys. 57(1985) 568.