Heat Rate Curves for the TEPPC 2026 CC

advertisement

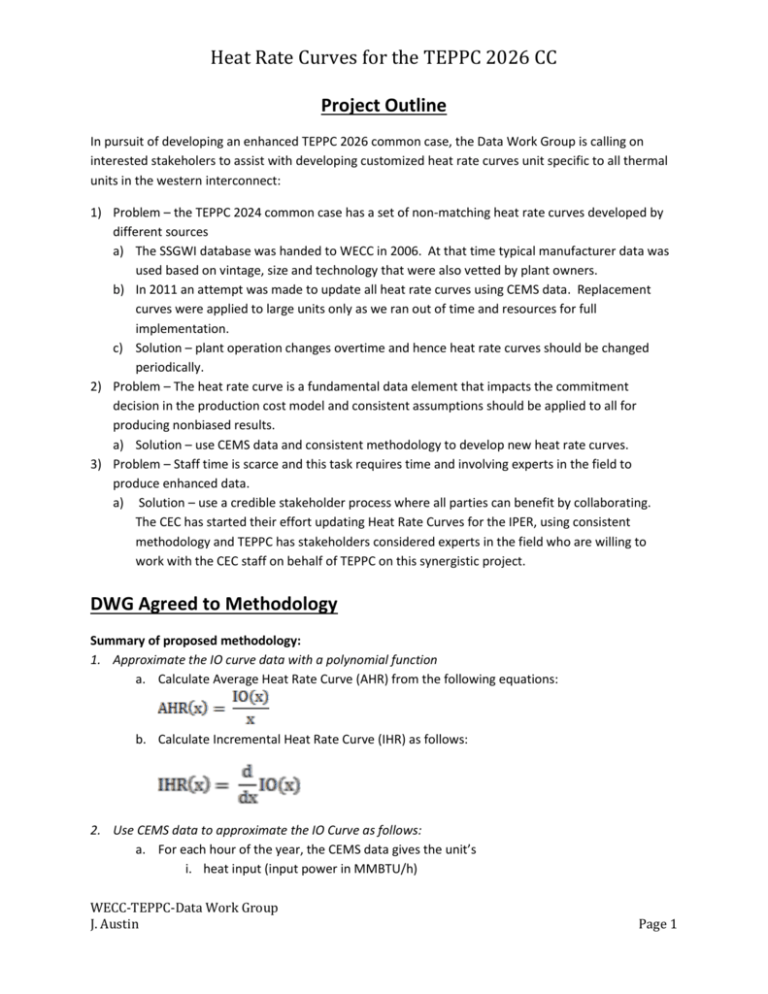

Heat Rate Curves for the TEPPC 2026 CC Project Outline In pursuit of developing an enhanced TEPPC 2026 common case, the Data Work Group is calling on interested stakeholers to assist with developing customized heat rate curves unit specific to all thermal units in the western interconnect: 1) Problem – the TEPPC 2024 common case has a set of non-matching heat rate curves developed by different sources a) The SSGWI database was handed to WECC in 2006. At that time typical manufacturer data was used based on vintage, size and technology that were also vetted by plant owners. b) In 2011 an attempt was made to update all heat rate curves using CEMS data. Replacement curves were applied to large units only as we ran out of time and resources for full implementation. c) Solution – plant operation changes overtime and hence heat rate curves should be changed periodically. 2) Problem – The heat rate curve is a fundamental data element that impacts the commitment decision in the production cost model and consistent assumptions should be applied to all for producing nonbiased results. a) Solution – use CEMS data and consistent methodology to develop new heat rate curves. 3) Problem – Staff time is scarce and this task requires time and involving experts in the field to produce enhanced data. a) Solution – use a credible stakeholder process where all parties can benefit by collaborating. The CEC has started their effort updating Heat Rate Curves for the IPER, using consistent methodology and TEPPC has stakeholders considered experts in the field who are willing to work with the CEC staff on behalf of TEPPC on this synergistic project. DWG Agreed to Methodology Summary of proposed methodology: 1. Approximate the IO curve data with a polynomial function a. Calculate Average Heat Rate Curve (AHR) from the following equations: b. Calculate Incremental Heat Rate Curve (IHR) as follows: 2. Use CEMS data to approximate the IO Curve as follows: a. For each hour of the year, the CEMS data gives the unit’s i. heat input (input power in MMBTU/h) WECC-TEPPC-Data Work Group J. Austin Page 1 Heat Rate Curves for the TEPPC 2026 CC ii. gross generation (output power in MW) b. Approximate the IO curve from the CEMS data as follows: i. scrub the CEMS data ii. graph the scrubbed dataset as a scatter plot iii. represent the scatter plot with a polynomial regression curve Summary of proposed processing: 3. Data Scrubbing a. Use the data that corresponds to the unit’s operating region b. Eliminate bad data points c. Scrubbing the data makes a big difference Scrubbed Not Scrubbed 4. Kevin’s Summary of steps to avert having issues with CEMS data: HP= Peak point; HR=Average Heat Rate; i=user set % of full load (unitized); 1. Develop IO curve based on filtered CEMS data by generation type a. This will be for gross generation b. Convert to average gross HR and unitize where: i. HP (i):= HP(i)/HP(Full Load) ii. HR (i):=HR(i)/HR(Full Load) c. Assumes unitized net HR shape = unitized gross HR shape d. Average unitized HR shapes to create generic HR shape by generation type e. Apply filter rules from step 3 when developing and calculating generic HR shape f. When reviewing CEMS data determine gross min and max generation (via plotting and or histograms) 2. Use CEMS data to calculate full load HR a. Use CEMS data to determine the gross full load fuel burn b. Full load HR:= gross full load fuel burn/net full load capacity (EIA-860 rating) 3. Develop rule to filter data and review results (Develop in work group): a. CEC QFER data is available to help develop rules-validate station service b. Develop rules to filter and review flags for Step 1 (Calc generic HR shape) c. Develop rules to filter and review flags for Step 2 (Calc full load HR) WECC-TEPPC-Data Work Group J. Austin Page 2 Heat Rate Curves for the TEPPC 2026 CC 5. Other considerations: The CEC started from Energy Velocity (EV) data that uses CEMS data. Although data is scrubbed and may save some time, first we have to be confident of assumptions made leading to discarding outliers. In the case of the CEMS data, EV assumed the following for typical range for Combustion Turbine operation: o 0 to 50 % ST produces 0 loading o 50 to 75% ST produces 50% loading o greater than 75% ST produces full output Use QFER data as an alternate data source for California plants Compute values for input to GridView WECC-TEPPC-Data Work Group J. Austin Page 3