26 41 13B.doc - Alberta Ministry of Infrastructure

advertisement

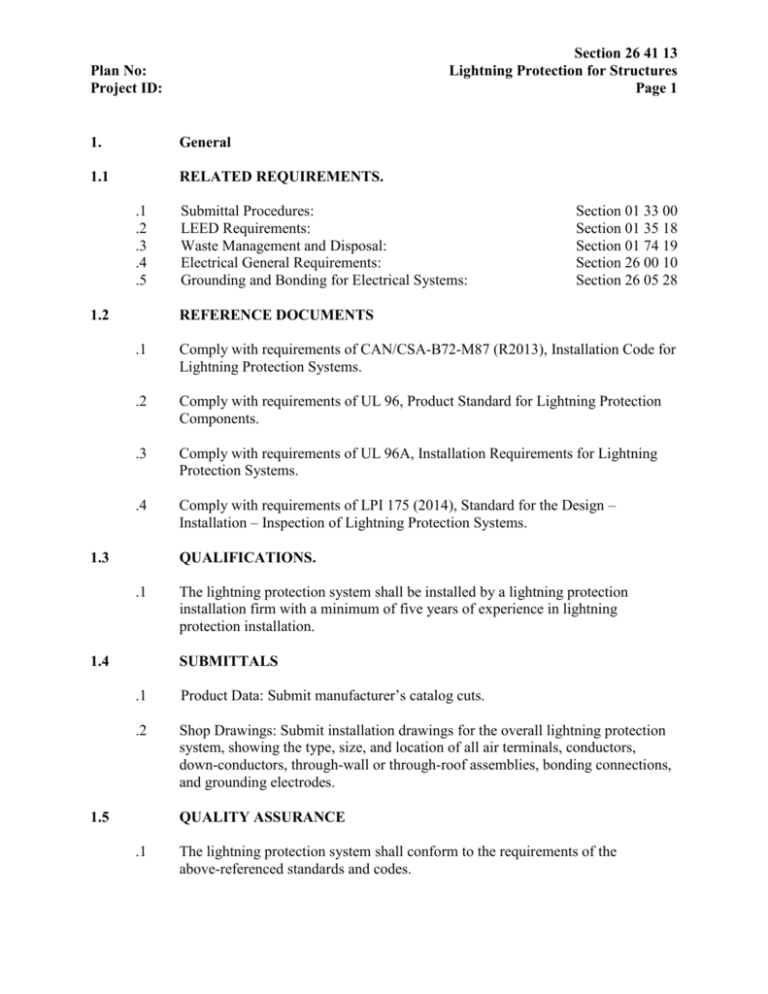

Section 26 41 13 Lightning Protection for Structures Page 1 Plan No: Project ID: 1. General 1.1 RELATED REQUIREMENTS. .1 .2 .3 .4 .5 1.2 Submittal Procedures: LEED Requirements: Waste Management and Disposal: Electrical General Requirements: Grounding and Bonding for Electrical Systems: Section 01 33 00 Section 01 35 18 Section 01 74 19 Section 26 00 10 Section 26 05 28 REFERENCE DOCUMENTS .1 Comply with requirements of CAN/CSA-B72-M87 (R2013), Installation Code for Lightning Protection Systems. .2 Comply with requirements of UL 96, Product Standard for Lightning Protection Components. .3 Comply with requirements of UL 96A, Installation Requirements for Lightning Protection Systems. .4 Comply with requirements of LPI 175 (2014), Standard for the Design – Installation – Inspection of Lightning Protection Systems. 1.3 QUALIFICATIONS. .1 1.4 The lightning protection system shall be installed by a lightning protection installation firm with a minimum of five years of experience in lightning protection installation. SUBMITTALS .1 Product Data: Submit manufacturer’s catalog cuts. .2 Shop Drawings: Submit installation drawings for the overall lightning protection system, showing the type, size, and location of all air terminals, conductors, down-conductors, through-wall or through-roof assemblies, bonding connections, and grounding electrodes. 1.5 QUALITY ASSURANCE .1 The lightning protection system shall conform to the requirements of the above-referenced standards and codes. Section 26 41 13 Lightning Protection for Structures Page 2 Plan No: Project ID: .2 Upon completion of work, the installer shall provide certification through the Lightning Protection Institute or Underwriters Laboratories that the lightning protection system is complete and complies with the applicable standards. 2 Products 2.1 MATERIALS .1 Materials used shall be new, and shall be listed and labeled in accordance with CSA and CUL requirements. The system components shall be the standard product of a CUL-listed manufacturer engaged in the production of lightning protection equipment. .2 Do not use any combination of materials that forms an electrolytic couple of such nature that corrosion is accelerated in the presence of moisture, unless moisture is permanently excluded from the junction of such metals. .3 Materials used in the lightning protection system shall comply with the listed requirements for the structure’s height and use. .4 Copper materials shall not be installed on or in contact with aluminum surfaces, nor surfaces that have been coated with aluminum bearing paints or epoxies. .5 Aluminum materials shall not be installed on or in direct contact with copper surfaces, or where exposed to runoff from copper surfaces nor within 300 mm of the point where the lightning protection conductor comes into contact with the earth. 2.2 COMPONENTS .1 Air Terminals: Copper or aluminum, 300 mm minimum length. .2 Cable: Listed copper or aluminum lightning protection conductor. .3 Ground rods: Copper, copper-clad steel, or stainless steel, minimum 12 mm diameter x 3000 mm length. .4 Ground plates: Copper or stainless steel, 0.40 m2 in surface area. 1.5 mm thick. .5 Ground loop: Listed copper lightning protection conductor or bare copper electrical conductor of equivalent size. Section 26 41 13 Lightning Protection for Structures Page 3 Plan No: Project ID: .6 Fittings and connectors: bolt-pressure, high compression, exothermic weld, or crimp type. 3 Execution 3.1 INSTALLATION OF SYSTEM .1 Install a full lightning protection system that meets the requirements of the abovelisted standards, consisting of air terminals or strike termination devices, interconnecting conductor, bonding connections, down-conductors, and ground electrodes. .2 All equipment shall be installed in a neat orderly manner. .3 Provide air terminals on outside roof edges and corners, along the ridges of pitched roofs and along the perimeter of flat or gently-sloping roofs. .4 Provide air terminals installed at intervals not to exceed 15 m on flat or gentlysloping roof areas greater than 15 m in width. .5 Provide conductors to interconnect all air terminals, and in mid-roof areas so that no point on the roof is more than 10 m away from a conductor. .6 Avoid sharp bends or kinks in the conductor. .7 Provide conductor fasteners at intervals no greater than 1.5 m. .8 Provide down conductors and grounding electrodes spaced at an average of no greater than 30 m around the perimeter of the structure. .9 Structural steel may serve as the lightning protection down conductor if it is electrically continuous and 4.8 mm or greater in thickness. Provide connections to structural steel at or near grade and connections to the ground electrodes spaced at an average of no greater than 18 m around the perimeter of the structure. 3.2 COORDINATION .1 Work with other trades to ensure a correct and neat installation. .2 Ensure final flashing and sealing of all roof penetrations are in accordance with the roofing manufacturer’s recommendations. .3 Acquire approval for type of lightning protection components adhesive to be used when in contact with roofing materials. Section 26 41 13 Lightning Protection for Structures Page 4 Plan No: Project ID: .4 3.3 The lightening protection system shall be inspected by the installer at substantial completion of the project to ensure system has been installed and able to provide protection as designed. COMPLETION .1 Submit as-built drawings of the completed lightning protection system. .2 Submit LPI or UL certification document. END OF SECTION