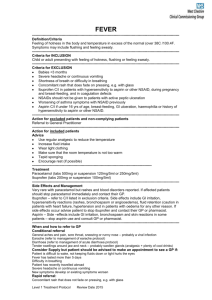

formal lab report-final (HPLC)

advertisement

Quality Assurance and USP Certification of Baby Aspirin Tablets using HPLC with UV detection Badrinath Dhakal 10/21/2009 Abstract High performance liquid chromatography (HPLC) with ultraviolet (UV) detection was used to quantitatively measure the amount of acetylsalicylic acid per tablet of the baby aspirin. The separation was performed using Shimadzu LC instrument with SPD-M 20 A Detector. The column was a C18, 5 µm, 150 mm length and 4.6 mm diameter and the mobile phase was a mixture of 60% methanol, 36% deionized water and 4% glacial acetic acid at a flow rate of 1.5 mL / minute at 238 nm wavelength. The average mass of ASA was found to be 57.76 mg/tablet which is only a 71.31 % of the claimed value. 1 1. Introduction: Aspirin is the acetate ester of salicylic acid. It is a white powder with a acidic taste. It is poorly soluble in water and somewhat better soluble in ethanol. Acetylsalicylic acid (aspirin) is one of the most commonly prescribed medicines to treat a variety of pain-related conditions, including rheumatic diseases and arthritis. It is often used as analgesic, antipyretic, anti-platelet and anti-inflammatory (1). It can be used to reduce the risk of death and lessen the damaging effects of an acute heart attack. It is also used to reduce the risk of heart attack and strokes in the persons who have already had a heart attack. It is a drug that permanently destroys the enzyme cyclo-oxygenase on contact. Cyclo-oxygenase is important for the body’s production of prostaglandins, which is a chemical that signals an injury or triggers pain. The use of aspirin has been shown to reduce the risk of Alzheimer’s disease [2, 3]. Aspirin is also effective in the prevention and treatment of colorectal cancer [4].It has anticoagulant properties and helps to prevent strokes and heart attacks. The use of aspirin has been shown to increase the risk of gastrointestinal bleeding, cause ulcerations, abdominal burning, pain, cramping, gastritis and liver toxicity. Large doses of salicylate have been proposed to cause tinnitus. As a part of quality assurance in pharmaceutical industries, the amount of active ingredient in a product is supposed to be determined on a regular basis. According to the protocol of the US Pharmacopeia (USP), any product regulated by the Food and Drug Administration (FDA) must contain the amount of active ingredient listed on the product label. The present study aimed to simulate a uniformity of dosage study of the baby aspirin, using HPLC protocols. First, the HPLC 2 was calibrated using the standard solution of acetylsalicylic acid and a linear range of calibration curve was known. Then the concentration of acetylsalicylic acid in each of the aspirin tablets was calculated using the calibration curve. There are various techniques for the determination of ASA, salicylic acid and their metabolites. Gas-Liquid Chromatography can be used to determine the ASA and its metabolites up to 1 µg/mL. GC methods are time –consuming and have been replaced by HPLC methods with ultra-violet detection, electrochemical detection, or mass spectrometry detection (5). Spectrophotometry is the earliest and most widely used method for measuring serum salicylate levels. In this technique, colorimetric determination of the salicylate is carried out using the intense red color of salicylate-Fe+3 complex. Similarly, the salicylate can be easily determined by Trinder method. This method involves the measurement of absorbance of the ferric ion-salicylate complex. This technique has a disadvantage that spontaneous (pH dependent) and enzymatic hydrolysis of aspirin though this problem can be solved by appropriate sample processing (1). The content of ASA in the mixture of ascorbic acid and ASA has been determined by LC method [6, 7]. Similarly ASA in combination with other active compounds was determined by differential spectroscopy (8), spectrofluorimetry (9), HPLC (10) Potentiometry (11) and Voltametry (12). The high performance liquid chromatography (HPLC) separation and subsequent identification of the spots by appropriate standards is the most frequently used technology. This method has several advantages like simplicity, reproducibility, high sensitivity (detection limit of about 100 ng/mL) and the possibility of simultaneous determinations of several aspirin metabolites together with aspirin itself in one sample. 3 2. Experimental 2.1. Reagents and materials Acetylsalicylic acid (ASA) MW = 180.16 gmol-1 was used as a standard. The baby aspirin sample was obtained from the St. Joseph (81 mg per tablet). Ten aspirin tablets were dissolved separately in the 50 ml volumetric flasks using the methanol-water diluent (64:36). Both standard and sample solutions were filtered using the luer-lock syringe filter before injecting into the HPLC. The HPLC used was Shimadzu LC20AT with SPD-M20 uv-vis diode array detection with the C18 stationary phase, 5 micrometer packing, column (4.6 mm internal diameter and 150 mm long). The mobile phase was made from 60% methanol, 36% deionized water and 4% glacial acetic acid. The wavelength was adjusted at 238 nm and the flow-rate was set to 1.50 mL per minute. 2.2. Preparation of standard solution A 49.70 mg sample of acetyl salicylic acid was accurately weighed out and dissolved with the diluent solution in a 50 mL volumetric flask. Using this solution five solutions of different concentrations were prepared following the dilution scheme shown in table 1. Five solutions of aproximately 1.0 mg/100 mL, 2.0 mg/100mL, 5mg/100mL, 8.0 mg/100mL and 10.0 mg/100mL concentration were prepared from the standard solution by appropriate dilution. 4 Table 1. Dilution of Aspirin Standards Exact concentration Volume of standard 1 Total volume 9.940 mg/100mL 5.0 mL 50 mL 7.952 mg/100mL 4.0 mL 50 mL 4.970 mg/100 mL 2.5 mL 50 mL 1.988 mg/100mL 1.0 mL 50 mL 0.994 mg/100mL 0.5 mL 50 mL 2.3. Preparation of samples Ten sample solutions were prepared by dissolving each baby aspirin tablet in each of the ten 50-mL volumetric flasks with the methanol-deionized water (64:36) diluent. Then diluted solutions of the samples were prepared by taking 2.0 mL of each solution in 25 mL volumetric flasks and diluted with the diluent solution. 2.4. Instrumentation and analysis 5 The injection of standard solution was started with the solution of lowest concentration. A 100µL aliquot of standard solution was injected into sample injection port and read the chromatogram of it on the computer. One chromatogram was obtained for each of the standard solutions. Similarly, a chromatogram for each of the ten unknown samples was obtained. Before running the unknown samples and between the subsequent injections of samples the HPLC was calibrated with the approximately 5.0 mg/100mL standard solution. Ultimately, the retention time and peak area for each of the unknown samples were obtained. Result and discussion Table 2. The peak areas and retention times of standard solutions Concentration of standards Retention time Peak area 0.994 mg/100mL 1.472 min. 128489 1.988 mg/100mL 2.404 min. 489338 4.970 mg/100mL 2.392 min. 1003061 7.950 mg/100mL 2.392 min. 1354373 9.940 mg/100mL 2.388 min. 1341161 blank 1.128 min. 819324 Table 2 shows that how the peak areas and retention time vary with the concentration of the standard solution. These data were used to draw a calibration curve (Fig1). The slope and 6 intercept of the line were recorded. Using the value of the slope and intercept, the exact concentration of each of the standard solutions were reevaluated. Similarly, the exact concentration of each of the unknown sample of baby aspirin was calculated by using the Equation (1). Mg of ASA/tablet = Peak area of unknown (4.97mg ASA Std.) 25×50 ……… (1) 100×Peak area of std. ×2 Calibration curve for aspirin y = 145043x + 236072 R² = 0.9806 1600000 1400000 peak area 1200000 1000000 Series1 800000 Linear (Series1) 600000 400000 200000 0 0 2 4 6 8 10 concentration, mg/100 mL Fig 1. Calibration curve for the aspirin. 7 Table 3. The peak areas and retention times of unknown samples (Baby aspirin) Samples (Baby aspirin) Retention times Peak areas D1 2.392 min. 1722197 D2 2.40 min. 1701991 D3 2.404 min. 1800832 D4 2.408 min. 1745001 D5 2.404 min. 1842195 D6 2.396 min. 1800516 D7 2.404 min. 1767297 D8 2.404 min. 1556586 D9 2.408 min. 1800357 D9 2.392 min. 1814338 D10 2.400 min. 1715173 8 Fig 2. Chromatogram of the std. 5.0 mg/100mL. Fig 3.Chromatogram of unknown sample of baby aspirin (D1) 9 Fig 3 represents the chromatogram of the unknown aspirin sample D1.The chromatogram seems to be almost similar to that of the 5.0mg/100mL standard sample (fig.2) which indicates that the unknown sample has the concentration very close to that of the standard one. Table 4. Mass of ASA in the different samples of baby aspirin. Unknown samples Peak area Mg of ASA /tablet % claim D1 1722197 56.80 70.12% D2 1701991 56.13 69.30% D3 1800832 59.39 73.32% D4 1745001 57.55 71.05% D5 1842195 60.75 75.01% D6 1800516 59.38 73.31% D7 1767297 58.28 71.96% D8 1556586 51.34 63.38% D9 1800357 59.38 73.30% 10 1715173 56.57 69.83% 10 Table 5. Statistical parameters determined for the unknown samples. Average Standard deviation RSD Mass per tablet 57.76 mg 2.6033 4.5068 % claim 71.31 0.0321 4.5068 The calibration curve indicates that the linearity of the line is satisfactory. There are two peaks in all the chromatograms despite we normally expect only one peak. Table 4 shows the masses of aspirin samples calculated from the peak area of absorption, slope and intercept from the calibration curve. Table 5 summarizes the result of the experiment in some statistical terms. The average mass per tablet of the baby aspirin was found to be 57.76 mg which is only 71.31 % of the claimed value. There might be a certain relation between the observation of more than one peak in chromatograms and low value of the results. Another peak in the chromatogram is similar to that of the salicylic acid. So, the sample might have been decomposed into salicylic acid to some extent and this resulted in the lower value of the result. When we take peak area of both the peaks and made the calculation, then the result came much closer to the claimed value. . 11 Conclusion High performance liquid chromatography (HPLC) with ultra-violet detection can be successfully employed to pass the uniformity of dosage for the quality assurance and USP certification of baby aspirin tablets. The result obtained in this experiment is lower than the expected one. The discrepancy between the experimentally obtained result and the theoretical value can be attributed to the fact that the aspirin sample underwent decomposition to salicylic acid to some extent. From the chromatograms, it is observed that there are clearly distinguishable two peaks unlike our expectation. Though HPLC with UV detection is most frequently used technique for routine analysis, it suffers from the disadvantage that the sample could undergo decomposition because of the length of time needed to prepare separately all the samples and consequently yields less accurate results. So, I would like to do the same kind of work with more appropriate sampling in the future. If the extent of decomposition of the aspirin is found out by any means, then the calculation would be made closer to the true value and it would certainly allow us to make a better decision. 12 Acknowledgement I would like to thank Dr. Ruth Ann Armitage for her valuable guidance and direction in carrying out this work. References: 1. Schror, Karsten . General aspects of Aspirin; Acetylsalicylic Acid, WileyBlackwell, Germany, 2009. 2. Mcgeer ,P.L.; Schulzer M.; McGeer, E.G., Neurology 1996 ,47,425. 3. Breitner, J.C.; Welsh, K.A.; Helms ,M.J.; Gaskell, P.C.; Gau ,B.A.; Roses ,A.D.; Pericak-Vance, M.A.; Saunders, A.M. Neuribiol.Aging 1995, 16, 523. 4. Elder DJE et al., The Lancet 1996,348, 484. 5. Ibrahim, H.,et al. J. Chromatogr.B 2007,857,59-66. 6. Kmetec, V., J.Pharm. Biomed. Anal.1992,10,1073-1076. 7. Thomis, R.; Roets, E. and Hoogmartens, J J. Pharm. Sci. 1984, 73, 1830-1833. 8. Dogan, H.N. and Duran, A. Pharmazie 1998,53,781-803. 9. Ramos Martos, N.; Molina Diaza, A.; Navalon, A.; Paya, I.O. and Captain Vallvey, L.F. J.Pharm.Biomed.anal. 2000, 23, 837-844. 13 10. Dipietra ,A.M.; Gatti, R. ; Andrisano , V. and Cavrini, V., J. Chromatogr A. 1996, 729, 355-361. 11. Kubota ,L.T.;Fernandes, J.C.B.; Rover ,L. and Oliviera Neto, G. Talanta. 1999, 50, 661-667. 12. Mielech, K. J. Trace Micropr. Technia. 2003, 21,111-121. 14