SUPPLEMENTARY MATERIAL Nanoparticle Tracers in Calcium

advertisement

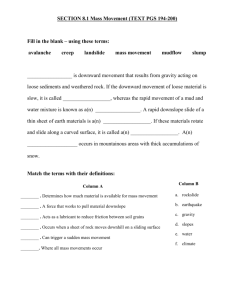

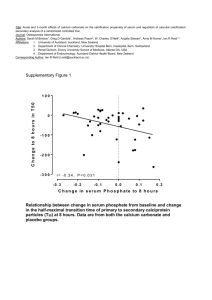

SUPPLEMENTARY MATERIAL Nanoparticle Tracers in Calcium Carbonate Porous Media Yan Vivian Li,1,* Lawrence M. Cathles,2 and Lynden A. Archer 3 1 Department of Design and Merchandising, Colorado State University, Fort Collins, Colorado 80523 2 3 Earth and Atmospheric Sciences, Cornell University, Ithaca, NY 14853 Chemical and Biomolecular Engineering, Cornell University, Ithaca, NY 14853 *Corresponding author: Yan Vivian Li, yan.li@colostate.edu, Tel: 970-491-7985, Fax: 970-4914855 Contents Pages (including cover page): 10 Text S1-S4 Figures S1-S4 1 Text S1: Nanoparticle Synthesis CNP-1 Jeffamine M1000 (XTJ 506) was purchased from Huntsman and Citric acid monohydrate (99.5%) from Sigma-Aldrich. They were used as received. DI water from Milli-Q (Millipore) system was used for all reactions and solution preparations. Citric acid monohydrate (180 g) is placed a large beaker (2 L vol) containing up to 900 ml DI water. In another beaker 540 g of jeffamine M1000 (XTJ 506) is diluted with 900 ml DI water. After complete dissolution (clear solution), the jeffamine solution is added to the citric acid solution under constant magnetic stirring. The mixture is stirred to a homogeneous solution which is then heated to ~ 70 °C under constant magnetic stirring to evaporate the water. When the volume of the mixture is reduced ~ 1 L, the materials are transferred to a crystallization dish of volume 1200 ml and further heated at ~ 70 °C to obtain a viscous (glue-like) material that is pyrolyzed at 300 °C in air for 8 h. The oven temperature is initially increased at a rate of 10 °C/min until 300 °C. The obtained black Cdot product is used as it is without any further purification. CNP-2 and CNP-3 Ethanolamine (99%) and Citric acid monohydrate (99.5%) were purchased from SigmaAldrich and were used as received. DI water from Milli-Q system (Millipore) system was used for all reactions and solution preparations. Citric acid monohydrate (378 g) is placed in a large beaker (2 L vol) containing 900 ml DI water. In another beaker, 330 g of ethanolamine is diluted with 900 ml DI water. After complete dissolution (clear solution), the ethanolamine solution is added to citric acid solution under constant magnetic stirring. The mixture is stirred to a homogeneous solution which is then heated to ~ 70 °C under constant magnetic stirring to remove water. When the volume is reduced to ~ 650 ml, the material is transferred to a glass 2 bottle (1L vol) and pyrolyzed at 200 °C in air for 8 h. The oven temperature is initially increased at a rate of 10 °C/min until 200°C is attained. The resulting black C-dot product is used as is without any further purification. SiNP-2 Amine functionalized Silica nanoparticles are diluted in 100 mL water to 2 wt% concentrations. Dansyl chloride and hydroxyl terminated poly (ethylene oxide) oligomer are added and stirred at room temperature for 12 hrs. The resulting suspensions are centrifuged and washed with water and methanol 3 times. PAVNP These polymer nanoparticles were prepared by mini-emulsion polymerization techniques. The following is a typical example. 1g of distilled acrylonitrile, 1g of sodium vinyl benzyl sulfonate, 1g of distilled divinylbenzene, 100mg of vinylpyrene, 60mg of sodium dodecylsulfonate and 20mg of azobisisobutyronitrile are added to 10g of water and emulsified with sonication before being transferred to a 70˚C oil bath and stirred for 12hrs. PAV nanoparticles (PAVNP) are collected by repeated centrifugation and redispersion in water (five times), followed by drying in vacuo until the weight is constant. CeNP A sodium fluoride (NaF) solution (10 mL, 0.2 M) is added dropwise to a cerium chloride (0.04M) and terbium chloride (0.004M) solution (40 mL). The mixture is then heated to 75 °C for 2 h under stirring. The resulting suspension is centrifuged (10 min, 8000 rpm) and washed with distilled water 3 times to obtain CeNP particles. 3 Figure S1. Fluorescent spectra of eight NPs. Excitation and emission wavelengths in fluorescent measurements are shown in each spectrum. 4 Figure S2. Characteristic properties of calcium carbonate sands. Properties in the insert tables and the size distribution plot are the supplier specifications 5 Text S2: Screening Column Design The inner diameter of the column was 1.8 cm, the height of the sand pack 10.1 cm. About 50 g of calcium carbonate sand was loaded into the column under wet conditions: The column is partially filled with deionized water and then the calcium carbonate sand is gradually added. Deionized water is needed so that the calcium carbonate sand is always introduced through a layer of water, which assures that no air is present in the water-saturated sand pack. The caps are attached snugly on the ends of the column using the four screws. The porosity of the sand is 55%. The pore volume of the sand pack is 14.34 ml. Figure S3. Scheme of the experimental apparatus. 6 Text S3: Protocol of Fluid Analysis A slug of solution (two to three pore volumes) is prepared with the concentrations of nanoparticles and KBr as described above. The solution is pumped slowly into the bottom of the column using a Masterflex® peristaltic pump (Cole Parmer). The tracer slug is followed by a similar volume of deionized water or brine containing no nanoparticles or KBr. The effluent is collected in a 2 ml plastic tube every 4 minutes. The flow rate through the column is 0.25ml/min during the entire injection. The concentration ratio (C/C0) is plotted against the pore volumes (PV) of injection to give breakthrough curves, where C0 and C are the concentrations of nanoparticles in the injected nanoparticle suspension and in the effluent, respectively. The concentrations of Br- ions in the effluent samples (C) and in the injection Br- concentration (C0) are used to derive the Br- breakthrough curves. 7 Text S4: Surface Observations SEM images of particles retained on the calcium carbonate sand surface for the CNP-3, SiNP1, SiNP-2, PSNP, PANNP, and CeNP are shown in Figure S3. Figure S3b shows the surface morphology of calcium carbonate sand surface covered by SiNP-1 after a brine column test. The particles appear to be partially embedded in the upper layer of calcium carbonate sand surface. The majority of embedded particles are separated from each other. The embedding phenomenon is only found in the case of brine solution and is not displayed for the pure water column test. The apparent embedding may be due to salt crystallization on the calcium carbonate sand surface when the surface is dried. An energy dispersive X-ray spectrum shows a chloride peak that can be interpreted as a thin layer of salt. Figure S6c shows that SiNP-2 particles are also retained on the calcium carbonate surface. Although it seems the covering by the SiNP-2 particles is uniform in the large view, particle clusters can be seen in the high resolution image. Significant particle aggregation is suggested by Figures S3d, e, and f. The PSNP particles shown in Figures S3d and e have negative zeta-potential, as does the calcium carbonate sand surface. Nevertheless, large clusters of aggregated particles have been captured by the calcium carbonate sand surface. Similar aggregations of the positively charged CeNP particles can be seen adhering to the calcium carbonate sand surfaces in Figure S3f. The adherence in the CeNP particles to the calcium carbonate sand surface is expected but their strong aggregation is a surprise because all the CeNP particles are positively charged. Figure S3e shows the aggregation of the PANNP particles is not as strong as for the PSNP and CeNP. The high resolution image shows the clusters consist of a few individual particles. In contrast, Figure S3a show that the CNP-3 uniformly cover the calcium carbonate sand surface. The CNP-3 particles show no embedding on the surface, and the insert images show no 8 significant particle aggregation. If a salt layer accounts for the appearance embedding in Figure S3b, it is not clear why the particles in Figures S3a and S3c are not similarly embedded. The reason for the apparent embedding in Figure 3b is thus not clear. Ca MgCl Na (a) CNP-3 (b) SiNP-1 (c) SiNP-2 (d) PSNP 9 (f) CeNP (e) PANNP Figure S4. SEM images of NPs residues on calcium carbonate sand surfaces after brine-wet column tests. The inserts show high resolution images of a portion of the surface. The insert in (b) shows EDX spectra of the calcium carbonate sand surface that is apparently embedded with SiNP-1 particles. Peaks of Na, Mg, and Cl suggest the presence of a thin layer of crystallized salt. 10