EMPIRICAL MODEL OF COMPOSITE ROCK

advertisement

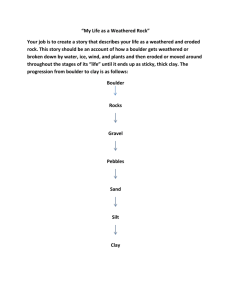

Empirical Strength Models, Elastic Modulus and Stiffness of Weathered Sandstone and Shale as a Composite Rock By Zainab Mohamed, PhD. Assoc. Prof., Faculty of Civil Engineering, Universiti Teknologi MARA, Malaysia zainab556@salam.uitm.edu.my Kamaruzzaman Mohamed, Haryati Awang Postgraduate students, Faculty of Civil Engineering, Universiti Teknologi MARA Malaysia ABSTRACT A geotechnical studies has been carried out on the typically weathered Kenny Hill sedimentary rock. The objectives are to determine the geotechnical properties related to wet tropical weathering. The mandatory classification by weathering grade was adopted to classify the interbedded rock mass which is mainly constitutes of sandstone and shale. The purposes are to characterize and classify the engineering properties, stiffness characteristics and behavior of weathered sandstones and shale and consequently their behaviour as a composite rock material. A series of rock material strength tests were carried out, i.e. a uniaxial compressive strength and point load strength. The empirical strength models were developed based on sandstone and shale experimental data. Thus the rock materials composite strength, elastic modulus and stiffness were mathematically modeled with respect to their respective weathering grades. Conclusively it was found that as a composite rock the strength models, modulus and stiffness were influenced by their state of weathering and deteriorated nonlinearly. KEYWORDS: weathering grade; sandstone; shale; rock strength; composite rock INTRODUCTION The rock mass assessment system and rock characterization methods have been previously established on a single type of rock which was assumed as an isotropic and homogenous. However practitioners reported that none of the established systems are relevant to interbedded rock mass which was also known as a problematic or difficult ground (Mohamed, 2004). It was reported that it would be a very tedious exercises to predict the behavior of such rock mass without first carrying out a thorough and systematic physical and engineering assessment. The engineering problems of interbedded rock are due to the differences in rock lithology, complex mode of failures and non-homogenous behaviour. Since early 90’s, some research studies had been initiated into heterogeneous rock formation which is also known as composite rock mass. The rock mass engineering model can be predicted either by simple rock classification system; empirical model, numerical modeling or a combination of any of them. A geotechnical research study has been carried out to characterize, classify and determine the engineering properties and behavior of weathered sandstones and shale named as composite material, dominating a Kenny Hill formation (Mohamed, 2004). From a rigorous experimental works the 1 empirical strength models are established and later become a mean to further understand and predict the modulus and stiffness characteristics of the composite rock with respect to their respective weathering state. The advancement of powerful statistical software has helped to expedite the analysis and hence developed an empirical rock mass model. Shakor et al. (1991) and Ulusay et al. (1994) had developed empirical models for sandstone rock mass by using multiple regression analysis from petrography and geo-mechanics data. Meanwhile Habimana et al. (2002) characterized the catalyst of quartzite sandstone and phyllite schist by adopting the Hoek-Brown failure criterion. However, Gokceoglu et al. (2003) has predicted the empirical model of rock mass based on the ratio of rock modulus and its quality index to the weathering grade of weak rock. They had respectively emphasis on the success of precise prediction of a single rock mass behavior hence contributed to the reduction to the cost of site investigation. This paper highlighted and discuss the development of an empirical relationship that express the strength and stiffness behavior of composite rock determine from the rigorous study on the typical rock formation of composite material (Kenny Hill rock mass). Figure 1 below illustrated four possible observed vertical profiles of weathered sandstone and shale by assuming the layers representing an ideal horizontal interbedding as recommended by Mohamed (2004). Highly weathered sandstone Moderately weathered sandstone Slightly weathered sandstone Slightly/highly weathered shale Highly weathered shale Highly weathered shale Slightly weathered shale Highly weathered sandstone Highly weathered sandstone Moderately weathered sandstone Slightly weathered sandstone Slightly/highly weathered shale Figure 1: A typical four ideal interbedding profile of weathered sandstone and shale named as composite rocks (after Mohamed, 2004) The figure above clearly indicated the heterogeneity of composite Kenny Hill rock mass. Generally as the state of weathering changes from slightly weathered to highly weathered, the physical and mechanical properties also deteriorate and degrade accordingly. Thus any combination of rock mass profile is expected to be unique which explained the difficulties often encountered and reported by practitioners working with Kenny Hill rock mass that resulted to possible unexpected delay on geotechnical work CHARACTERISATION AND CLASSIFICATION BY WEATHERING GRADE The outcrop of sedimentary cut slope at Section 8, Shah Alam, Selangor was selected as a case study. The outcrop is geologically known as Kenny Hill rock mass. From the field mapping, the cut slope constituted of slightly to highly weathered sandstone and shale with traces of quartz veins. The two dominating materials were differentiated physically, where weathered sandstone is a fine grained gritty texture while weathered shale is smooth and powdery. It was very difficult to ascertain the grade of weathering through physical observation therefore some methods of testings had been used 2 to characterize and classify the weathered sandstone and shale. The objective is to determine the degree of deterioration and disintegration of both materials hence explained the complex mode of slope failure observed in-situ. The details of finding have been discussed by Zainab 2004. Table 1 summarizes the physical classification of weathered sandstone and shale looking from the quality of weathering grade, hand sample hardness, rebound hardness, surface texture, dry density and slake durability. It was found to be a gradual physical degradation and deterioration of both materials with respect to the increase in grade of tropical weathering. Hence, the type of composite rock models as shown in Figure 1 , each is expected to has different strength and stiffness characteristics with any combination of the respected weathered materials. Table 1: Physical properties of weathered sandstone and shale of Kenny hill formation Rock samples Hardness (hand sample) Slightly weathered Sandstone (BP2g, BP2s) Very hard and intact Moderately weathered Sandstone (BP3) BP4 Hard and slightly disintegrate Highly weathered Sandstone (BP5) Slightly weathered shale ( S2 ) Rebound hardness Surface texture and lamination Dry density kN/m3 > 30 Smooth and intact 2.4 – 2.6 Slake durability index (%) 98 5-30 Slightly massive and gritty 2.2 – 2.7 94 10-15 Partially massive and gritty 2.0 – 2.7 - dented Very gritty and massive 1.5 – 1.9 46 < 20 Soapy and intact 2.4 – 2.5 92 Breakable and easily slake 10-20 Powdery and slightly massive 2.2 – 2.4 96 Breakable and slake dented Powdery, gritty and massive 2.5 – 2.6 92 Breakable and easily disintegrate Easily broken and disintegrate Hard and slake Moderately to Highly weathered shale S5 S5a GEOMECHANICAL STRENGTH A series of strength test was carried out according to ISRM 1981, suggested method of testing. Some blocks of sandstone and shale have been sampled from the site according to the weathering grade and later prepared for uniaxial compressive strength and point load strength tests. The objective is to determine the material strength as it varies from slightly weathered to highly weathered i.e from rock to soil like state. The strength and stiffness of the weathered composite materials i.e a matrix of weathered sandstone and weathered shale are then formulated. Uniaxial Compressive Strength The test was carried out according to the suggested method with some modification to the procedure of testing .The non-homogeneity of weathered sandstone from Kenny Hill formation constitute of a wide range in uniaxial compressive strength values. The broad varieties are due to the aggressive tropical rock weathering and the unique weathering pattern of the sedimentary rock. The removal of inherited physical properties of weathered sandstone and shale materials due to sample preparation process resulted to the mechanical properties obtained was a representative of tropical weathering 3 characteristics of the tested samples. However by repeating the test on as many samples with the same quality of weathering has enabled the comparison of the strength deterioration of sandstone and shale being concluded. Table 2 summarized the uniaxial compressive strength (c) of weathered sandstone and shale which has been physically characterized and clustered accordingly. The data obtained in the first column was statistically analyzed and has been reclassified to reflect the true uniaxial compressive strength of the weathered rock by its quality of weathering grade. Point Load Strength A point load strength test is not popular as a method for geotechnical assessment among civil engineer in Malaysia however result shows that by using a lower scale of load cell and higher sensitivity of strain measurement, the point load strength (Isp50) of slightly to highly weathered sandstone and shale has been successfully measured. Table 3 summarized the result of the point load strength index tested perpendicular to the sample lamination. Table 2: Summary of σc2 for weathered sandstone and shale samples from Kenny Hill rock mass Rock samples BP2G (*22) BP2S (*26) BP3 (*15 ) BP5a (*8) BP2a BP5b S2 (*8) S2’ S5’ S5a’ c Range ( MPa) 12.64 - 100.24 17.18 - 102.25 13.03 - 87.40 9.96 - 39.64 10.98 - 36.64 - c2 Range (average) (MPa) 12.63 - 97.22 (48.34) 17.03 - 97.26 (54.16) 12.76 - 85.55 (42.95) 18.88 - 64.49 (42.79) 8.85 - 35.23 (18.41) 6.26 - 34.89 (15.24) 6.83 - 20.79 (10.87) 5.33 - 28.70 (10.86) (*) no.of samples, BP2: weathered sandstone, c2: UCS equivalent to diameter to length ration equal to 2 Standard deviation 21.07 21.27 23.98 16.33 - Reclassified c2 (MPa) 27.91 - 71.36 (*17) 32.53 - 72.31 (*17) 20.81 - 45.12 (*9) 34.73 - 59.56 (*5) 71.23 - 97.26 (*12) 12.63 - 31.67 (*11) - S2’,S5’,S5a’: c2 of weathered shale derived from empirical correlation Table 3: Summary of Isp and Isp50 for sandstone and shale perpendicular to sample lamination Rock samples BP3 (32) BP4 (30) BP5b (29) S2 (30) S5 (51) S5a (29) Isp Range (MPa) Isp50 0.08 - 9.52 0.02 - 0.43 0.01- 0.43 0.11-2.07 0.14 -2.26 0.05-1.88 0.09 - 9.94 0.03 - 0.46 0.01 - 0.53 0.13-2.08 0.18 - 2.56 0.06 - 1.41 Average (MPa) Isp Isp50 3.13 0.17 0.06 0.73 0.47 0.45 3.36 0.18 0.07 0.76 0.50 0.45 (..) no. of samples , Isp: Point load perpendicular to sample lamination, Isp50: Point load equivalent to 50 mm diameter- 4 Fresh to slightly weathered Highly weathered Fresh to slightly weathered Isd – slake durability (%) σc- Uniaxial cpmressive strength Iks –%tage of medium quartz It - Stiffness index Ikj-% of quartz Ktt – Confined compressive strength (MPa) Is –Point load strength (parallel) (MPa) Ia – Point load anisotropy index Figure 2: Summary of the physical and mechanical properties of sandstone and shale by the quality of weathering grade. The summary of the physical and mechanical properties of sandstone and shale with respect to their degree of tropical weathering is tabulated in Table 2, Table 3 and Figure 2. From the results the qualitative and quantitative methods of assessment have conclusively showed the gradually decreased of weathered sandstone physical properties and strength differences from 6% to 33% from BP2 to BP5. Similarly the complex properties of weathered shale resulted to strength differences from 17% to 28% from S2 to S5’. EMPIRICAL STRENGTH MODEL The principles of empirical strength model of sedimentary rock is based on the assumptions that the physical properties of sandstone and shale gradually changed from fresh to highly weathered, hence their respective strength reduces proportionately with the grade of weathering . It was assumed that the four empirical models in Figure 1 were based on a column weathering profile of rock mass. The analyses were carried out in sequence of the strength of weathered sandstone; weathered shale ; weathered composite material dominated by sandstone and weathered composite material dominated 5 by shale . In the composite rock material models, the structure orientation was assumed to be ideally horizontally paralleled. In summary, the research design of the empirical models were based on the following assumptions: quality of weathered rocks below the ground increases with depth quality of rock weathering is based on strength envelopes. broad range in strength index are due to inherited non-homogeneity of weathered rock the highest and the lowest strength indices are recorded for each weathered group of rock the average strength index of rock from each group was used as a guideline the empirical correlations of material strength was used to predict the mechanical properties of composite rock material. Uniaxial Compressive Strength to Point Load Strength of Weathered Sandstone From the laboratory results, the uniaxial compressive strength of the weathered sandstone, (σ, σ1 or σ2) versus the respective point load strength index, Isp50 , were plotted on semi-log graph as shown in Fig 3. The strength correlation had two different profiles. The uniaxial compressive strength of slightly weathered to moderately weathered sandstone has relatively linear correlation to point load strength as shown by equation (1), meanwhile moderately weathered to highly weathered sandstone strength concludes logarithmic correlation as shown by equation (2). Both equations have significant strength correlation of more than 90%. 1 10 I sp50 40.8 with R2 = 0.93 (1) 2 12.6 ln( I sp50 ) 65.4 with R2 = 0.97 (2) Further data regression from slightly to highly weathered sandstones produced power regression line as in equation (3), with degree of significant equal to 0.91. 60.6( I sp50 ) 0.3 with R2 = 0.91 (3) Strength to Elastic Modulus and Stiffness of Weathered Sandstone The elastic modulus of weathered sandstone was determined from uniaxial compressive strength test. Graphical plot of the uniaxial compressive strength (σ2) with respect to elastic modulus (E50) and stiffness index (Ii) is as shown in Fig. 4. From Eqn. 4 and Eqn. 5 respectively with each R2 value equal to 0.52 and 0.23 had concluded a low significant of correlations obviously observed from the scattered data. E50 0.4 2 12 with R2 = 0.52 (4) I i 0.0053 2 0.94 with R2 = 0.23 (5) 6 Highly weathered Moderately140 140 weathered Slightly weathered 120 120 y1 = 9.8823x + 40.839 R2 = 0.9305 UCS index (MPa) y1 =9.8823x + 40.839 100 100 Indeks KMS (MPa) 80 80 60 60 y2 = 12.563Ln(x) + 65.396 2 y2 = 12.563Ln(x) + 65.396 R = 0.9719 40 40 R2 = 0.9719 20 20 0.001 0.001 0.010.010 1 0 1.000 100 0.100 10 Isp (50) (MPa) 10.000 -20 Isp50 (MPa) Figure 3: Correlation of σ versus Isp50 of weathered sandstone 60.00 60 y = 0.3989x + 11.975 R2 = 0.5201 y = 0.3989x + 11.975 R2 = 0.5201 1.20 1.2 50 50.00 1.0 1.00 40 0.8 0.80 Indeks tegar E50(MPa) 40.00 30 30.00 0.6 0.60 20 0.4 0.40 20.00 y = -0.0052x + 0.9497 R2 = 0.23 y = - 0.0052x + 0.9497 R2 = 0.23 10 10.00 E50 0 0.2 0.20 It 0.00 0 Stiffness index, It Modulus elasticity, E50 1.40 1.4 20 40 20 40 E50 60 80 60 KMS (MPa) 80 100 Indeks UCSLinear Index Indeks tegar (Indeks(MPa) tegar) Linear (E50) 100 120 0.00 120 Figure 4: Correlation of σ2 versus E50 and Ii of weathered sandstone. Strength Index, Is of R2 = 0.9305 Weathered Sandstone Strength index, Is, is defined as the ratio of uniaxial compressive strength to point load strength and is a dimensionless parameter. It represents the ratio of compressive strength to the tensile strength properties of a rock material. Based on the plotted data as shown in Fig 5 and Fig 6, the strength index of sandstone correlated exponentially to σ2 (Eqn. 6) and Isp50 (Eqn. 7) as follows: I s 1853 e 0.005 2 with R2 = 0.9 (6) 7 I s 0.02( I sp50 )0.7 with R2 = 0.98 (7) Based on the above correlations, it is observed that at σ2 > 60 MPa , Is< 125, the strength index reduction rate is not significant probably due to the high brittleness of weathered sandstone. On the contrarily the weathered sandstone having σ2 < 60 MPa and Is>125, can be due to reduction in the brittleness indicated by a large increment of strength index at low compressive strength. The profile revealed the boundary between rock-like weathered sandstone and soil-like highly weathered sandstone. The similar behaviour was also observed at the boundary of point loads strength of 1 MPa. The sandstone behaved as a brittle material when the point load strength is more than 1 MPa, otherwise it can be considered as a ductile material. 1250 1250 1000 750 Indeks Kekuatan Ik Strength index, Ik 1000 750 500 500 -0.0513x 1853e y =y = 1853e R = 0.8987 R2 = 0.8987 -0.0513x 2 250 250 0 0 0 0 20 20 40 40 60 80 100 60 80 100 UCS Index (MPa) Indeks KMS (MPa) 120 120 140 140 Figure 5: Correlation of strength index to uniaxial compressive strength of weathered sandstone 0.08 40 0.07 0.08 0.07 0.06 Strength index 0.06 0.05 Nisbah kekuatan 0.05 0.04 0.04 0.03 0.03 yy = 0.0164x = 0.0164x0.7133 R2= 0.9839 R = 0.9839 0.7133 2 0.02 0.02 0.01 0.01 0.01 0.01 0.1 0.10 0.00 1.00 1 Isp(50) (MPa) Isp50 (MPa) 10 10.00 Figure 6: Correlation of strength index to point load index of weathered sandstone Empirical Model of Weathered Shale The indirect method of empirical strength model for weathered shale is an alternative method for predicting its equivalent uniaxial compressive strength.At the same time, the correlation between material properties with respect to its quality of weathering grade can been predicted. From the minimal experimental results of uniaxial compressive strength test and point load test on slightly 8 weathered shale, a semi-log graph was established. The correlation between the two strength indices showed a curvilinear correlation as shown in Fig 7 producing an empirical correlation as in eqn (8), 2 s 14.10 Is sp50 4.50 with R2 = 0.94 (8) Hence the reduction in strength of weathered shale is predicted from the point load strength index. The uniaxial compressive strength of the shale is in the range of 6 MPa to 29 MPa for moderately weathered. For slightly weathered shale, the ranges of strengths are slightly higher range from 29 MPa to 35 MPa. 40 35 40 y = 14.104x + 4.5026 2 R = 0.9359 Indeks KMS (MPa) UCS index (MPa) 35 30 30 25 25 y =14.104x + 4.5026 R2 = 0.9359 30 15 10 20 15 10 5 5 0.001 0.010 0.001 0.100 0 1.000 0.01 1 Isp(50) (MPa) Isp(50) (MPa) 10.000 10 Figure 7: Correlation of UCS to Isp(50) of slightly weathered shale Uniaxial Compressive Strength to Elastic Modulus and Stiffness The correlation between the uniaxial compressive strength with elastic modulus, E50, and intact properties, Ii are plotted in the same graph as shown in Fig 8. The graphical plot produced two empirical correlations. The correlation of elastic modulus of the shale with respect to compressive strength can be predicted using Eqn. 9, E50 ' 0.46 2 ' 8.03 with R2 = 1.0 (9) and similarly the strength index of weathered shale is predicted by using eqn (10) below, I c 4.8 2 s ' ( 0.57) with R2 = 0.99 (10) It was found that the elastic modulus decreases linearly with the decrease in uniaxial compressive strength, meanwhile the stiffness of material exponential increases with a decrease in uniaxial compressive strength . The intersection of the two lines indicated the boundary between soil-like weathered shale on the left and rock-like weathered shale on the right hand side. 9 3030 2.5 2.5 25 25 2 2.0 y = 0.4563x + 8.0298 y = 0.4563x + 8.0298 R =1 R2 = 1 20 E50 (MPa) 20 1.5 1.5 15 15 1 1.0 10 10 -0.572 y = 4.7759x y = 4.7759x R = 0.9896 R2 = 0.9896 -0.572 0.5 2 5 Stiffness index, It Modulus elasticity, E50 2 0.5 5 0 0.000 5.000 00 5 10.000 15.000 10 20.000 25.000 15 20 25 UCS Index (MPa) Indeks KMS (MPa) 30.000 0 40.000 35.000 30 35 040 Figure 8: Uniaxial compressive strength w.r.t. elastic modulus and stiffness index of weathered shale. Empirical Strength Model of Composite Rock The empirical strength model of each type of composite rock was determined by the same approach of analysing individual strength of sandstone and shale. Each composite model was developed base on the combination of each group of experimental data for weathered sandstone and shale. It was found that the strength boundary of weathered materials changes from soil-like material to rock-like material at σ2 = 35 MPa or equivalent Isp50 = 0.3 MPa. The strength correlation for the respective weathered state was plotted by using normal scale graph as shown in Fig 9 and Fig 10. The respective empirical strength correlations are simplified below: 2 Rock-like composite or Soil-like composite or General composite material composite 24 ln ( Issp50 ) 51 with R2 = 0.94 (11) composite 25 ln ( Issp50 ) 49 with R2 = 0.97 (12) 2 2 composite 52 ( Issp50 ) 3 with R2 = 0.90 (13) 2 composite 28 ( Issp50 ) 6 with R2 = 0.94 (14) composite 18 ln ( Issp50 ) 50 with R2 = 0.85 (15) 2 Subsequently the correlation between the uniaxial compressive strength with elastic modulus, E50, and stiffness Ii of composite is as shown in Fig. 11. The graphical plot produced two empirical correlations. The elastic modulus and stiffness index of the composite can be predicted by the following equations, E50 ' 0.45 2 ' 8.2 with R2 = 0.7 (16) I s 0.42 ln 2 2.24 with R2 = 0.72 (17) Equation (16) for composite material is close to that weathered shale (Eqn. 9) and the stiffness index (Eqn. 17) is close to Eqn. 10. Hence it can be deduced that the presence of shale has greatly influenced the strength of Kenny Hill rock mass. 10 Boundry soil/rock? BP n Syal 140 140.000 120 120.000 100 80 Indeks KMS (MPa) UCS index, (MPa) 100.000 60 80.000 y = 24.622Ln(x) + 49.162 R2 = 0.9695 40 60.000 20 y = 24.622Ln(x) + 49.162 R2 = 0.9695 0 40.000 Isp(50) > 0.3 Isp(50) < 0.3 20.000 y = 27.653x + 5.7399 y = 27.653x + 5.7399 R2 =2 0.9382 R = 0.9382 0.000 0.000 0 11.000 2 2.000 3 3.000 4 54.000 6 5.0007 6.000 8 97.00010 8.000 9.000 Isp50 (MPa) Isp(50) (MPa) Isp < 0.3 Isp > 0.3" 10.000 Figure 9: Plot of UCS wrt ISp for weathered composite using boundary Isp =0.3 MPa Figure 10: Plot of UCS wrt Isp for weathered composite using boundary UCS=35 MPa 11 Figure 11: Correlation of UCS to Elastic modulus and stiffness of composite rock CONCLUSION The systematic assessment method and the comprehensive data analysis on the weathered sandstone and weathered shale had been carried out to establish their respective strength models as individual material and composite material. Even though there is no direct laboratory works has been carried out on composite sample the results have shown some promising findings on the prediction of the strength behaviour of composite sandstone and shale rock of Kenny Hill formation. The respective empirical equations can be used either to predict the elastic modulus, stiffness or strength indices from a simple test result as simple as a point load strength test. In real life problem, it is very important to the practitioner to be able to characterise and determine the geotechnical behaviour of weathered sandstone and shale as a composite rock mass for cost saving and safe geotechnical design. ACKNOWLEDGEMENT This paper only highlighted and discuss a sub topic of a comprehensive research studies funded by Ministry of Science, Technology and Innovation Malaysia ( IRPA 09-02-01-0006EA006 ) and is gratefully acknowledge. The authors would like to thank , Institute of Research and Consultancy and the Faculty of Civil Engineering UiTM for their support. REFERENCES 1. BSI 5930. (1999) Code of Practice for Site Investigations. Sect. 6. London. British Standard Institution. 2. Gokceoglu, C., R. Ulusay, H. Sonmez (2000) Factors affecting the durability of selected weak and clay-bearing rocks from Turkey, with particular emphasis on the influence of the number of drying and wetting cycles. Intel. Journal Engineering Geology 57.: 215-237. 3. Habimana, J., V. Labiouseb, and F. Descoeudres (2002) Geomechanical characterization of cataclastic rocks: experience from the Cleuson–Dixence project. International Journal of Rock Mechanics & Mining Sciences 39, 677-693. 12 4. ISRM (1981) Rock Characterization, Testing and Monitoring-ISRM Suggested Methods. Oxford. Pergamon Press. 5. Mohamed, Z. (2004) Engineering Characterization of Weathered Sedimentary Rock for Engineering work. Unpublished PhD thesis. National University of Malaysia. 6. Mohamed, Z., A.G. Rafek, and I. Komoo (2004) Geomechanical Behaviour of Interbedded Rock Mass of Kenny Hill Formation, Selangor. Malaysia. Proc. of the 4th Asian Symposium on Engineering Geology and The Environment. Geological Society of Hong Kong. 7: 179 7. Shakoor, A., R.E. Bonelli (1991) Relationship between petrographic characteristic, engineering index properties and mechanical properties of selected sandstones. Bulletin .of Engineering Geology 28: 55-71. 8. Ulusay, R., K. Tureli, M.H. Ider (1994) Prediction of engineering properties of selected sandstone from its petrographic characteristics. Intel. Journal Engineering Geology. 37:135157. © 2007 ejge 13