4.6 Hot Work Policy Purpose Hot work refers to any process that may

advertisement

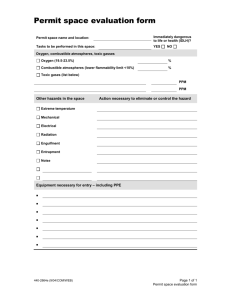

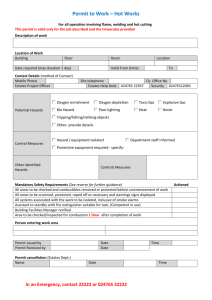

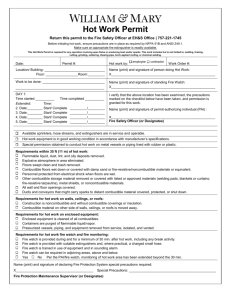

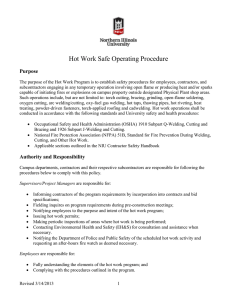

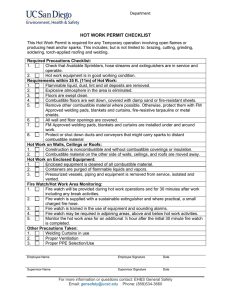

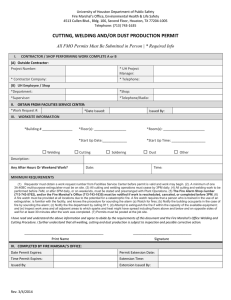

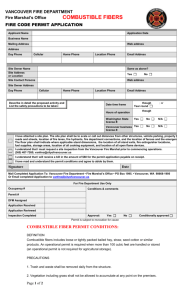

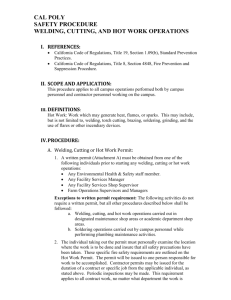

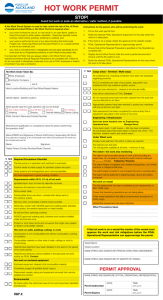

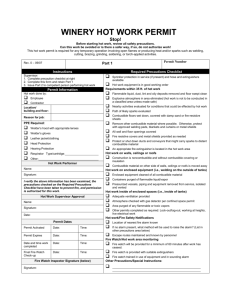

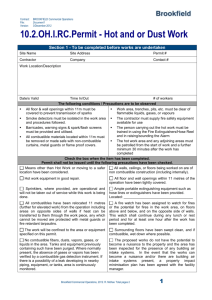

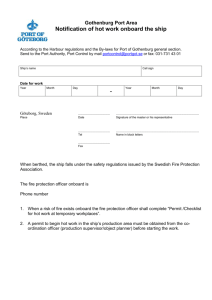

4.6 Hot Work Policy Purpose Hot work refers to any process that may generate an uncontrolled spark or flame that could be a danger to a workplace, causing a burn to an employee or fire if it comes into contact with a flammable material. At [Employer/Organization Name], Hot Work Permit is only required when performing torch cutting and welding in an area where it is not normally done. This policy outlines the procedures that employees of [Employer/Organization Name] must follow when performing hot work. This policy applies to all regular and part-time employees of [Employer/Organization Name], and all contract employees working on the premises. Policy All employees of [Employer/Organization Name] must follow the Hot Work Procedures outlined below, including the use of the Hot Work Permit. Only authorized persons trained in proper use of, and precautions associated with the equipment used for torch cutting and welding may access and use this equipment. Due to the serious nature and high hazard potential of hot work, any employee not following these procedures will be immediately disciplined. Procedure Before beginning any hot work, each employee or contractor will identify and control any workplace hazards, using the Hot Work Permit. The applicable supervisor will initial and date the Hot Work Permit. If there will be a shift change during the work an additional hazard assessment will be done. Hot Work permits will be obtained from the applicable supervisor and are mandatory for contractors, or for any work that takes place in a confined space, or near activities involving volatile materials. Hot Work permits will be given to the Health and Safety Representative. Persons doing hot work are required to wear all prescribed Personal Protective Equipment including foot protection and eye protection. A first aid kit and eye wash station will be near the work area and functional. Any combustible materials will be removed from the work area, put at a safe distance from the work area, or protected from the hot work. Enclosed equipment, including duct work will be cleaned of all combustible vapour. Duct openings should be covered with fire resistant material and checked when the work is complete. If any cutting is being done, employees are required to wear a respirator to prevent the employee from breathing in metal fumes which may be toxic. A fire extinguisher will be placed or kept in the immediate work area. The fire extinguisher will be checked on a regular basis to verify that it is operational. Ensure that all cracks in the floorboards, along baseboards and walls, and under doors have been blocked using a fire resistant material. Close all windows and doors. Combustible floors must be kept wet with water or covered with fire resistant materials or damp sand. Use water only if electrical circuits have been de-energized. Make sure that all ceiling surfaces and walls have been covered with a heat resistant material and inspect them once the work has been done to ensure that they have not heated up. All work areas will be monitored for at least one hour after the work has been completed for signs of ignition. In the event of emergency, refer to the relevant procedures found in the Emergency Procedures. Training Maintenance employees will be trained in both the technical and safety aspects of their work. The training will include but not be limited to: Hazard identification Safe procedures for torch cutting and welding Fire and safety precautions Control methods Proper use and maintenance of the welding equipment Proper use and maintenance of the personal protective equipment (PPE) Proper use and completion of the Hot Work permit Training records will be maintained the employee’s file. Additional Resources Hot Work Permit Document Management Effective Date: Revision Date: Hot Work Permit Complete this checklist before beginning any Hot Work. Work Area: Employee Performing Work: Supervisor: Date: Before Work Begins The area has been inspected for combustible materials. All combustible materials have been moved out of the work area or protected from the work. Enclosed equipment has been cleaned of combustible materials. Ducts have been properly and safely covered. A fire extinguisher is immediately available in work area. All cracks and other openings have been blocked. If using water on the floor, all circuits have been de-energized. Yes No Yes No Yes No Yes No Yes No Yes No Yes No Make sure all of the above actions are completed prior to beginning work. After Work is Completed All ceilings, walls and floors have been inspected for signs or indications of ignition (heating up). The work area was monitored for Yes No Yes No one hour after completing the work for possible ignition. Employee Signature: Supervisor Signature: