Agilent HPLC

advertisement

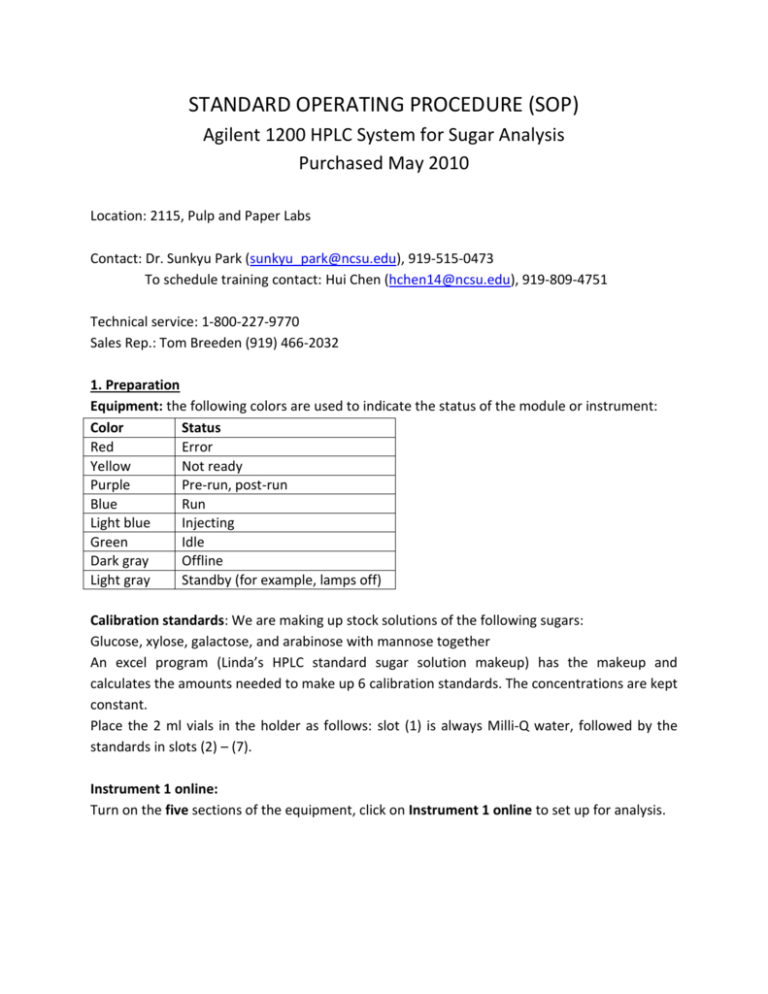

STANDARD OPERATING PROCEDURE (SOP) Agilent 1200 HPLC System for Sugar Analysis Purchased May 2010 Location: 2115, Pulp and Paper Labs Contact: Dr. Sunkyu Park (sunkyu_park@ncsu.edu), 919-515-0473 To schedule training contact: Hui Chen (hchen14@ncsu.edu), 919-809-4751 Technical service: 1-800-227-9770 Sales Rep.: Tom Breeden (919) 466-2032 1. Preparation Equipment: the following colors are used to indicate the status of the module or instrument: Color Status Red Error Yellow Not ready Purple Pre-run, post-run Blue Run Light blue Injecting Green Idle Dark gray Offline Light gray Standby (for example, lamps off) Calibration standards: We are making up stock solutions of the following sugars: Glucose, xylose, galactose, and arabinose with mannose together An excel program (Linda’s HPLC standard sugar solution makeup) has the makeup and calculates the amounts needed to make up 6 calibration standards. The concentrations are kept constant. Place the 2 ml vials in the holder as follows: slot (1) is always Milli-Q water, followed by the standards in slots (2) – (7). Instrument 1 online: Turn on the five sections of the equipment, click on Instrument 1 online to set up for analysis. Instrument 1 offline is used when samples are being run and you want to check or export finished work. Under Method and Run Control: At this time, the mobile phase used is Milli-Q water (no need for degassing). Check the level of the brown bottle before starting any sequences. Fill if necessary and reset the volume control by the following means: Click on instrument go to more pump then bottle filling. Actual volume reset to 1.0 liter (if you fill up the bottle) and click on OK. The following two statements should also be checked: a. Prevent analysis if level falls below 0.100. b. Turn pump off if running out of solvent. Baseline: On instrument control diagram: hit on to start the ovens, pumps and lamps. Wait until all sections are ready (diagram color from yellow to green). Observe the baseline in Online Plot (View-> Online Signals-> Signal Window 2); it should be stabilized before you start running samples. 2. Sample Requirement pH requirement for HPLC samples: 5 – 7. For samples with pH< 5, neutralization is necessary. a. Aliquot sample (5 – 10 mL) in a small flask or beaker. b. Neutralize to pH 5 – 6 using calcium carbonate (ACS grade). c. After reaching pH 5 – 6, allow sample to settle and decant off the clear liquid. The pH of the liquid after settling will be approximately 7. d. Prepare the sample vial by passing the decanted liquid through a 0.2 µm filter. Caution: When calcium carbonate is used excessively, solid precipitation might occur even after filtering, and could damage the column. Use calcium carbonate as little as possible, and wait a sufficient time for settlement after neutralization. 3. Acquisition Standards Sugars analysis A standard method and sequence for sugar analysis will be developed and named Sugars1. This will be a set flow rate, analyzing time for each sample, injection volume, injection depth and oven temps. If there is a parameter you want to change: use the “save as” icon first to rename the method and then make your changes. Establishing a method or editing a method: 1. Go to method. 2. Click on desired method then OK. 3. Back to method in the menu. 4. Click on: Edit Entire Method. There are four sections a. Method info; b. Instrument Acquisition which will let you change: flow rate, stop time, injector info, and oven temps; c. Data analysis; d. Run time checklist. 5. File save as >>>>whatever you want to name the new method. Setting up a Sequence a. Go to Sequence Template. b. Under the Sequence menu, find Sequence Parameters…, input your name for operator and in subdirectory tell it where the date is to be saved. It should contain the following: path C:\chem32\1\data\your folder name. Select Auto for the data file naming system. c. For Part of methods to run, select According to RuntimeChecklist. d. Select the Post-Sequence Cmd/Macro checkbox, and then from the drop box, select STANDBY. Enter an nRdy Timeout of 30 minutes. OK the dialog box. If you want to turn off the pump and oven after signal acquisition, select macro “SHUTDOWN.MAC”, go. e. Under the Sequence menu, find Sequence Output…, select the Print Sequence Summary Report option along with the Report to Printer and Print individual reports for each run as well, options. f. Specify the destination for individual reports as the File, as specified here, not as specified with each method. Select the File Settings as you need, then OK the dialog box. In this case, you don’t need to specify report for each sample analysis. Adding a sequence and start up to run samples: 1. Click on: Sequence. 2. Go to Sequence Table to input sample identification, vial position, sample name, method name that you want to use for sugar analysis, Injection times per Vial (shown as Inj/Vial), and usually please set it as 1. 3. Use Append Line to add new samples, also use Insert, Cut, Copy and Paste as you need. 4. After finishing setting up your sequence, click on OK to save your sequence. 5. Click on Run Sequence or Icon Start on the control board to start running samples. 4. Data Analysis Evaluating the data: 1. Click on your data file: 2. Click on a specific sample. If it’s a calibration standard, it will show the four peaks plus a lot of junk peaks if you do not specify data purifying standards in your method. 3. To clean up the unnecessary peaks, highlight the icon that has a peak with an X on it. 4. Drag and box the junk peaks to remove, (If you remove a good peak, use the green arrow by a peak icon to undo). 5. Save icon is at the very right. Exporting the data: 1. Double click the sample you want to export. 2. Click Report -> Specify Report to edit report calculation and print style. 3. Under destination: unclick screen, click file, uncheck all but xls, and then click OK. 4. Go Report -> Print Report to save the report in your targeting folder. 5. C:\chem32\1\data\your folder name to save your report into your hard disc. 5. Shut-down Process 1. Click on the icon off in the lower right corner of the diagram board to shut down the ovens, pumps and lamps. 2. Turn off the five sections of the equipment.