QCOPS-BX00-HSS-CER-000003_3 Excavation Certificate 02

advertisement

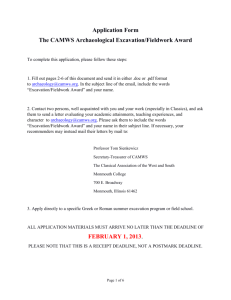

Excavation Certificate Date: QCOPS-BX00-HSS-CER-000003_3 Isolation Cert. No: (where applicable) Associated PTW No: This Excavation Certificate must be used in conjunction with the PTW form for all PTW ground disturbance work (excavations or penetration). A box must be ticked for all Yes/Required/NA options and all text fields must be completed or the section struck out. Brownfield areas: Endorsing Authority is required for all excavation or trenching 1.2m or greater in depth. (Endorsing Authority is not required for driving stakes, auguring, boring or piling, where there is no risk of a person entering the space for these activities.) Project Greenfield Areas: Endorsing Authority is required when the conditions on this certificate cannot be met. Step A: Excavation Details Location of Work: Proposed Length of excavation: Proposed Depth of excavation: Existing Ground Condition (if known): Proposed Excavation Date: Prevailing Weather: Equipment to be used: (include excavator & bucket size/s) Step B: Installed Services B Part i) General Copy of Guidelines for work near QGC pipelines (QCOPS-OPS-HSS-GDL-000001) attached (must accompany the PTW application for any excavation within a 15m pipeline exclusion zone). Where excavation will occur within a 15m pipeline exclusion zone, provide the name of the QGC Superintendent or 1. delegate consulted for this excavation: Name:_____________________________________________________________ 2. 3. Yes The “QGC Crossing process” is being followed If yes, provide Crossing Reference Number: (contact crossingQGC@bg-group.com for information) Additional precautions are required for underground or overhead electrical hazards (If yes, detail in Step G) Installed services protected, isolated, supported or removed: If yes, detail (e.g. when the excavation is open): 4. B Part ii) Excavation to identify installed services 1. This certificate is for the identification of installed services (pot holing only) 2. General area to be pot holed is marked on a map and attached (including general coordinates) 3. Excavation to identify services will only be undertaken using: vacuum trucks and/or hand digging 4. Maximum distance of pot holing from point of Excavation will be 1.0m 5. Services will be identified with Color Coded Conduits as per QGC Excavation Procedure QCOPS-BX00-HSS-PCE-000007 6. HOLD POINT QGC to assess service location and identification. B Part iii) Excavation of installed services 1. Full assessment conducted and installed services located (evidence attached) 2. Exact location of installed services marked prior to site works excavation Step C: Excavation C Part i) General 1. Competent Safety Observer will be nominated for excavation & role will be identified on PTW form at sign on 2. A warning system will be established and used during the operation of all mobile equipment Barriers & appropriate signage are available and will be installed at excavations, wells, pits, shafts, etc.(including controls 3. for general public where applicable) 4. No mechanical excavation permitted directly above live services, irrespective of the depth (includes auguring/boring) No mechanical excavation permitted below or horizontally, within 1 metre of any known live service (includes 5. auguring/boring) 6. Is a level 2 risk assessment required? (required if steps 4 & 5 above cannot be achieved) All excavations to expose services will be vacuum or hand excavated (without picks or crowbars) until fully exposed and 7. witnessed by the Contractor Supervisor (and QGC where identified Step E) All mechanical excavation within close proximity (defined as one bucket width) of the 1 metre exclusion zone will be 8. undertaken with a blunt scraper (no tiger teeth permitted and equipment must be pre-approved) 9. Equipment, materials and spoils will be set back a minimum 1.0 m from the excavation 10. Personnel will be protected from loose rock or soil Hazardous atmosphere could or does exist (consider proximity to portable generators and running machinery) 11. If yes refer to PTW form Steps 4,5B, 8 & 9 and hot work certificate where applicable) C Part ii) Wet working conditions 1. Precautions will be taken to protect personnel from accumulation of water 2. Pumps or water removal equipment will be monitored by a competent person 3. Surface water will be controlled or diverted This cert. is referenced in Procedures -Excavation QCOPS-BX00-HSS-PCE-000007 and Permit to Work QCOPS-BX00-HSS-PCE-000002 Page 1 of 2 NA Excavation Certificate QCOPS-BX00-HSS-CER-000003_3 C Part iii) Excavation - Other 1. Excavation requires battering to comply with QGC procedure and Excavation Work Model Code of Practice 2. Excavation requires benching to comply with QGC procedure and Excavation Work Model Code of Practice 3. Excavation requires shoring to comply with QGC procedure and Excavation Work Model Code of Practice 4. Excavation will be inspected for signs of stress cracking or other cave-in signs (detail is step F) 5. Toe boards installed around deep excavations or trenches where a risk from falling objects has been identified Bridges and walkways for excavations over 1.8m in depth will be equipped with handrail/s or if there is a risk of falling into 6. the excavation all pedestrian crossings must be fitted with handrails regardless of the depth 7. Ladders will be placed every 9m or access ramps installed where required for access and egress No heavy loads will be operated or located in the Zone of Influence unless a competent person has designed the ground 8. support system installed 9. No personnel will work on sloped or benched excavations above other personnel 10. No loads will be lifted above personnel working in trenches 11. No vibrating/impact machinery will be operated within the zone of influence where personnel are working in the excavation 12. Excavation Rescue Plan has been developed, approved and is attached. This will be communicated to the work group. 13. Emergency response equipment readily available where hazardous atmosphere could or does exist 14. Personnel are trained in use of personal protective and emergency rescue equipment Yes N/A Step D: Risk Assessment (RA) Yes N/A 1. 2. 3. 4. Persons will be entering / working in the excavation. A Confined Space RA has been conducted and is attached. When attached, tick one: Excavation does not meet the criteria for Confined Space Excavation is a confined space and a Confined Space Certificate is attached An approved SWMS for the excavation activity developed and attached (all components identified on this certificate must be addressed in the SWMS) This excavation work requires Endorsing Authority Approval (meets criteria in 1st orange text box page 1) Where the conditions/controls on this certificate cannot be met, work must not proceed until a level 2 RA has been undertaken and the work approved to proceed by the relevant SSM for the area. (SSM approved Level 2 RA attached) Step E: Level of Direct Supervision Required During Identification & Exposure & During Mechanical Excavation 1. 2. Yes N/A Permit Holder must be on site at all times A contractor supervisor must be present for: i. the identification and exposure of all known services ii. mechanical excavation within the 15m zone (only permitted > 1m away from the live service and then only after the service has been fully exposed. Equipment must be pre-approved). 3. Where required: The contractor supervisor name and mobile number is: A QGC approved representative must be present during identification, exposure of: i. all live gas or electricity services, regardless of pressure; ii. any other service within 3m of a live gas or electrical service; iii. other services identified as high risk during assessment (such as water and fiber optic); and iv. mechanical excavation within 3m of the services identified in i, ii or iii above (only permitted > 1m away from the live service and then only after the service has been fully exposed). Where required, Permit Issuer to provide the agreed nominated QGC representative/s name/s and mobile number/s: Step F: Trench/Excavation Inspection Type Pre Start Daily After Rain HOLD POINT. QGC Excavation Endorsing Authority inspection required prior to personnel entering excavation/trench If yes, EA to sign at time of inspection indicating excavation is safe: Name: Signature: Time: Random Check Yes Date: Other inspection requirements: Step G : Further Details and Controls Required (e.g. limits of approach for overhead power lines): Completion of Excavation Inspections must be confirmed in STEP 8 on the PTW form Step H. Excavation Certificate Issue The Excavation described on this certificate is in my opinion safe to be conducted when all the stated precautions are adhered to. Relevant Plant /Pipeline / Superintendent or Delegate Name: Signature: Date: [Required when excavation takes place within a 15m exclusion zone.] Endorsing Authority Name: Signature: Date: Signature: Date: [Where identified as required] *Permit Issuer Name: Permit Holder: I am aware of the terms and conditions this certificate is issued under and agree to abide by them at all times. Permit Holder Name: Signature: This cert. is referenced in Procedures -Excavation QCOPS-BX00-HSS-PCE-000007 and Permit to Work QCOPS-BX00-HSS-PCE-000002 Date: Page 2 of 2 N/A