MOD-032 Model Data Requirements & Reporting Procedures

advertisement

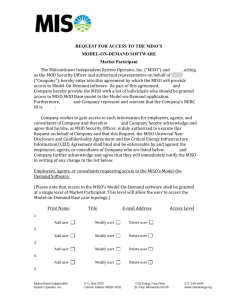

MISO MOD-032 Model Data Requirements & Reporting Procedures Version 1.1 September 5, 2015 i This Page Left Intentionally Blank MISO ii Contents 1 Introduction ............................................................................................................................. 1 1.1 Purpose ....................................................................................................................... 1 1.2 Process Overview ........................................................................................................ 1 1.3 Responsible Entities .................................................................................................... 2 1.4 Data Submittal Delegation Options .............................................................................. 2 2 Data Submission Requirement ................................................................................................ 4 2.1 Load Serving Entity ...................................................................................................... 4 2.2 Generator Owner ......................................................................................................... 4 2.3 Transmission Owner .................................................................................................... 4 3 Power Flow Model Development ............................................................................................. 6 3.1 Data Format ................................................................................................................. 6 3.2 Level of Detail .............................................................................................................. 6 3.2.1 MOD Naming Conventions ................................................................................... 7 3.2.1.1 MOD Project Files .......................................................................................... 7 3.2.1.2 Bus/Load/Generation (BLG) Profiles .............................................................. 7 3.2.1.3 Device Control Profiles .................................................................................. 7 3.2.2 Definitions ............................................................................................................. 8 3.2.2.1 Project Types ................................................................................................. 8 3.2.2.2 Project Statuses............................................................................................. 8 3.2.3 Modeling Criteria................................................................................................... 8 3.2.4 Area Interchange .................................................................................................. 9 3.2.5 Ratings ................................................................................................................. 9 3.2.6 Standard Case Effective Dates ............................................................................. 9 3.2.7 Modeling of Wind Farms ......................................................................................10 3.2.8 Dispatch...............................................................................................................11 3.2.9 Load Modeling .....................................................................................................11 3.2.10 Tie Lines ..............................................................................................................11 3.3 Scenarios ....................................................................................................................11 3.4 Schedule .....................................................................................................................12 3.5 Power Flow Data Checks ............................................................................................12 3.6 MOD Training & Access ..............................................................................................13 MISO i 3.6.1 MOD Access Levels.............................................................................................13 3.6.2 Obtaining Access to MOD ....................................................................................13 3.6.3 MOD Training ......................................................................................................14 4 Dynamics Model Development ...............................................................................................15 4.1 Data Format ................................................................................................................15 4.2 Level of Detail .............................................................................................................15 4.2.1 Power Flow Representation .................................................................................16 4.2.2 Dynamics Representation ....................................................................................16 4.2.2.1 Generators....................................................................................................16 4.2.2.2 Static VAR Systems & Synchronous Condensers .........................................16 4.2.2.3 HVDC ...........................................................................................................17 4.2.2.4 Load .............................................................................................................17 4.2.2.5 Protection Relays ..........................................................................................17 4.3 Scenarios ....................................................................................................................18 4.4 Schedule .....................................................................................................................18 4.5 Dynamics Data Checks ...............................................................................................19 5 Standard Generator & Load Component Model List ...............................................................20 5.1 Generator Models .......................................................................................................20 5.2 Exciter Models ............................................................................................................21 5.3 Turbine/Governor Models ...........................................................................................22 5.4 Turbine Load Controller Models ..................................................................................23 5.5 Power System Stabilizer Models .................................................................................23 5.6 Compensator Models ..................................................................................................23 5.7 Wind Models ...............................................................................................................24 5.8 PV Models ..................................................................................................................24 5.9 Load Characteristics Models .......................................................................................24 6 Converting Legacy to Newer Models ......................................................................................26 6.1 Generators ..................................................................................................................26 6.2 Exciters .......................................................................................................................26 6.3 Turbine/Governors ......................................................................................................26 6.4 Turbine Load Controller ..............................................................................................26 6.5 Power System Stabilizer .............................................................................................27 6.6 Compensator ..............................................................................................................27 MISO ii 6.7 Wind ...........................................................................................................................27 6.8 PV...............................................................................................................................27 7 Composite Load Model ..........................................................................................................28 7.1 Parameter Derivation Based on Load Composition .....................................................29 7.2 Example Composite Load Model Based on Load Composition ...................................30 8 Short Circuit Model Development ...........................................................................................32 9 MOD-032-1 – Attachment 1 ...................................................................................................33 10 Data Checks ........................................................................................................................35 10.1 Power Flow Data Checks ............................................................................................35 10.2 Dynamics Data Checks ...............................................................................................36 11 Entity Lists ...........................................................................................................................38 Appendix 1 Transmission Planner Compliance .........................................................................39 MISO iii 1 Introduction 1.1 Purpose MISO develops a series of power flow and dynamics simulation models which are used by MISO and its members for performing reliability and economic planning studies needed to fulfill various NERC and Tariff compliance obligations. Pursuant to requirement R1 of MOD-032-1, MISO as a NERC Planning Coordinator (PC), and its NERC Transmission Planners (TPs) have jointly established a set of common procedures for submitting data needed for developing planning models as described in this document. Pursuant to requirement R1.3 the Requirements and Reporting Procedures manual is posted on the MISO web site at the following location: https://www.misoenergy.org/PLANNING/MODELS/Pages/MOD-032.aspx The purpose of this document is to outline these data reporting procedures needed to support the development of power flow and dynamics simulation base case models that realistically simulate steady state and dynamic behavior of the transmission system in a manner compliant with MOD-032. The PC is also responsible for submitting models for its planning area to the ERO or its designee to support creation of the Interconnection-wide cases that includes the Planning Coordinator’s planning area per MOD-032 Requirement R4. 1.2 Process Overview Figure 1-1 provides a high-level overview of the modeling process. Additional details on the modeling process are outlined in Sections 3 & 4. MISO 1 MISO Data Owners MISO •Send annual data request •Submit data to MISO •Review data & compile into set of models •Post models for review ERO/Designee MISO Data Owners •Create Eastern Interconnection models •Incorporate feedback into models •Send models to ERO/ designee •Review models •Provide corrections & feedback Figure 1-1: Modeling Process Overview 1.3 Responsible Entities Pursuant to requirements in MOD-032-1 R2, data owners are responsible for providing the data necessary to model their assets to its Transmission Planner(s) and Planning Coordinator(s) as described in this document. Transmission Planners may notify data owners that they do not want the data and that it should only be sent to the planning coordinators. Data owners and their respective data submission responsibilities are noted ahead: Generator Owners (GO) are responsible for submitting modeling data for their existing and future generating facilities with a signed interconnection agreement Load Serving Entities (LSE) are responsible for providing their load forecasts corresponding to the scenarios developed Transmission Owners (TO) are responsible for submitting data for modeling their existing and approved future transmission facilities Balancing Authorities (BA), Transmission Service Providers (TSP), Resource Planners (RP) currently do not have any data submittal requirements, since they don’t own facilities 1.4 Data Submittal Delegation Options Generator Owners: GOs will coordinate with their interconnected TO in order to ensure that their data is consistent with the TO submitted topology. The generator owner may request assistance from the transmission owner in ensuring the equipment is modeled in the format requested. The transmission owner will let the generator owner know if they are willing to assist. GOs may MISO 2 submit their data directly to MOD/MISO or work with their interconnected TO to submit the data to MOD/MISO on their behalf. GO’s are expected to submit directly to MOD/MISO unless they have made arrangements with their interconnected Transmission Owner to submit data on their behalf. If arrangements have been made, it must be communicated in writing to MISO at TAMModeling@misoenergy.org Load Serving Entities: LSEs will coordinate with their interconnected TO in order to ensure that their data is consistent with the TO submitted topology. In alignment with MISO BPM-011, each LSE is responsible to work with applicable Electric Distribution Companies (EDC) to coordinate the submission of EDC forecast data in areas that have demand and energy that are subject to retail choice. The load serving entity may request assistance from the transmission owner in ensuring the loads and equipment is modeled in the format requested. The transmission owner will let the load serving entity know if they are willing to assist. LSEs may submit their data directly to MOD/MISO or work with their interconnected TO to submit the data to MOD/MISO on their behalf. LSEs are expected to submit directly to MOD/MISO unless they have made arrangements with their interconnected Transmission Owner to submit data on their behalf. If arrangements have been made, it must be communicated in writing to MISO at TAMModeling@misoenergy.org Transmission Owner Submittal of Unregistered Entities As a best modeling practice it is desired that TOs would also submit modeling data at their disposal for unregistered entities in their footprint. There is no obligation to do so and additionally no compliance repercussions relating to the data provided, however it is desired to produce higher quality models. MISO 3 2 Data Submission Requirement MOD-032 Attachment 1 lists the modeling data to be submitted and is summarized by responsible entity below. Section 9 includes Attachment 1 for reference. MISO as a PC will send a message confirming an entity’s participation in fulfilling their modeling obligation/compliance with MOD-032 at the end of the model building cycle. 2.1 Load Serving Entity In coordination with their interconnected TO, the LSE shall provide the aggregate demand levels for each of the scenarios specified in Section 3. The load serving entity shall use the bus numbers assigned to them by the interconnecting transmission owner. Table 2-1 provides a summary of the data required to be submitted by the LSE. Table 2-1: Data to be submitted by the LSE Steady-State Aggregate demand on a bus level Location of new expected loads Dynamics Load Composition or Characteristics 2.2 Generator Owner In coordination with their interconnected TO, the GO shall provide the necessary data to model their generating facilities. The generator owner shall use bus numbers assigned to them by the interconnecting transmission owner. Table 2-2 provides a summary of the data required to be submitted by the GO. Data for existing and planned generators with executed interconnection agreements should be submitted. Actual dispatch will be determined based on study needs. Table 2-2: Data to be submitted by the GO Steady-State Generator parameters Generator step-up (GSU) transformer data Seasonal output capabilities Station Service Load Reactive Power Compensation1 Wind Collector System Dynamics Generator Excitation System Turbine-Governor Power System Stabilizer Protection Relays 2.3 Transmission Owner The TO is responsible for providing the necessary data to model the items listed in Table 2-3. 1 Additional reactive power support equipment (such as a switched shunt) used to maintain an acceptable power factor at the Point of Interconnection MISO 4 Table 2-3: Data to be submitted by the TO Steady-State System Topology Buses AC transmission lines HVDC transmission facilities Transformers Reactive Power Compensation Static VAR Systems (SVS) Initial Generator Output in MOD (to be submitted by the TO whose model control area the unit is located within)* Dynamics Static VAR Systems HVDC Facilities FACTS Devices Protection Relays *In the circumstance where the model Control Area is not a Transmission Owner, then the LBA may submit the data instead of the control area Transmission Owner if MISO is notified via email by both parties to TAMModeling@misoenergy.org MISO 5 3 Power Flow Model Development 3.1 Data Format Power Flow model data is to be submitted to MISO via MISO’s Model on Demand (MOD) Tool in the MOD format as explained ahead. Models are developed using the Siemens PTI PSS/E software program. Data submitted should be compatible with the MOD and PSS/E versions currently specified by MISO. Modeling data requests and notifications are sent to the Planning Subcommittee mailing list. Individuals can subscribe to the list at the following location: https://www.misoenergy.org/Pages/ListsSignup.aspx 3.2 Level of Detail On at least an annual basis each data owner is required to submit the following model data to MISO’s Model on Demand (MOD) database: 1. Transmission projects intended to be approved by MISO (moved to Appendix A) in the upcoming MTEP; to be submitted by Transmission Owners a. This includes the projects that are submitted to the MISO Project Database by member companies by September 15 of each year. 2. Generators with executed generator interconnection agreements (GIA) & associated network upgrades. At a minimum, all generators with a nameplate greater than 20 MVA or a facility with an aggregated nameplate greater than 75 MVA must be modeled in detail (except for those meeting the exclusion criteria as specified in the NERC BES definition) and additionally Blackstart Resources identified in the Transmission Operator’s restoration plan. 3. Bus/load/generation and devices profiles, which include: a. Load forecast for each scenario at the bus level representing a 50/50 forecast coincident with the company peak; to be submitted by LSE b. Corresponding generation limits and level for each scenario in the model list (Pmin, Pmax, Qmin, Qmax, Pgen); Generation limits/capabilities to be submitted by Generation Owner. Generator owner shall submit generator capabilities (Pmax/Qmax) that correspond to a point in the reactive capability curve, Generation output to be submitted by Transmission Owners c. Settings on regulating equipment such as transformers, switched shunts and HVDC data; to be submitted by data owner 4. Updates and/or corrections to approved future generation and transmission projects 5. Any corrections that need to be made to existing system modeling in the MOD Base Case. Data owners shall provide facility retirement updates. GOs and LSEs will coordinate with their interconnected TO in order to ensure that their data is consistent with the TO submitted topology. GOs and LSEs may submit their data directly to MOD/MISO or work with their interconnected TO to submit the data to MOD/MISO on their MISO 6 behalf. GO’s and LSE’s are expected to submit directly to MOD/MISO unless they have made arrangements with their interconnected Transmission Owner to submit data on their behalf. If arrangements have been made, it must be communicated in writing to MISO at TAMModeling@misoenergy.org If the data has not changed since the last submission, a written confirmation that the data has not changed is sufficient. Such confirmation should be sent to MISO as the Planning Coordinator and the appropriate Transmission Planner. MISO correspondence should be sent by email to TAMModeling@misoenergy.org. Bus/Load/Generation (BLG) Profiles need to be submitted on an annual basis if the generation limits/parameters change depending on the season. The data submitted must be sufficient to perform reliability and economic studies on the bulk electric system (BES) as defined by NERC2. To that extent, relevant data associated with sub100 kV facilities may also need to be provided. 3.2.1 MOD Naming Conventions Files submitted to MOD (projects, profiles, etc.) must follow naming conventions specified in the following sub-sections. 3.2.1.1 MOD Project Files MOD project files are used to make transmission system topology changes. Filenames should contain the company name acronym and the MTEP Project ID (MTEP_PRJID). This project ID is available in the MISO Project Database. Company name (acronym) should appear first in the project file name, see example below: Example: ITC-MTEP_PRJID- project_name.prj 3.2.1.2 Bus/Load/Generation (BLG) Profiles Bus/Load/Generation (BLG) profiles contain information about loads and generation and are specific to individual scenarios (year, season, load-level). BLG profiles cannot be used to modify transmission topology. The BLG profile name should mention the specific scenario, the MTEP cycle, and the Company name (acronym) per example below: Example for 2016 Summer peak profile: 2016SUM-MISO14-XEL-BLG.raw 3.2.1.3 Device Control Profiles Device profiles contain information about settings on regulating equipment such as transformers, switched shunts and DC data. Device profiles cannot be used to modify transmission topology. The device control profile name should contain the specific scenario, the MTEP cycle, and the Company name (acronym), see example below: Example for 2016 Summer peak profile: 2016SUM-MISO14-ATC-DEV.raw 2 http://www.nerc.com/pa/RAPA/BES%20DL/bes_phase2_reference_document_20140325_final_clean.pdf MISO 7 3.2.2 Definitions 3.2.2.1 Project Types MTEP Appendix C: Projects that are proposed by TOs, Stakeholders, or MISO staff for which specific needs have not yet been established, but that are thought by the sponsor to be a potentially beneficial expansion. MTEP Appendix B: Projects that are demonstrated to be a potential solution to an identified reliability, economic, or policy need. MTEP Appendix A: Projects that have been justified to be the preferred solution to an identified reliability, economic, or policy need, and have been reviewed and approved by the MISO Board of Directors. Non-MTEP MISO: Projects submitted by MISO members that are Non-Transferred facilities and that don’t fall under the jurisdiction of the MTEP process, as detailed in Section 4.2.3 (Project Reporting Guidelines) in the Transmission Planning BPM. Non-MISO Network: Projects submitted by Non-MISO members/Non-MISO electric system Base Case Change: Projects submitted to make changes to the MOD Base Case Generator: Projects submitted to add generators with approved interconnection service 3.2.2.2 Project Statuses Conceptual: Conceptual or vision plans Alternative: Alternatives to preferred projects in MTEP Appendix B Proposed: Projects that require additional review and are subject to change Planned: Projects that have completed the TO planning process and TO intends to permit and construct the project In Service: In Service Generator Correction: Base case change to be submitted for correction of MOD Base Case 3.2.3 Modeling Criteria Criteria for inclusion of projects in the base models are shown in Table 3-1. Table 3-1: Project Inclusion Criteria Type & Status Target MTEP A Planned Proposed Alternative Conceptual In Service Correction MTEP Appendix A N/A IN MODELS N/A N/A N/A N/A N/A MTEP IN MODELS Appendix B NOT IN MODELS NOT IN MODELS NOT IN MODELS N/A N/A N/A MTEP IN MODELS Appendix C NOT IN MODELS NOT IN MODELS N/A NOT IN MODELS N/A N/A N/A N/A N/A N/A N/A Non-MTEP MISO MISO N/A IN MODELS 8 Non-MISO Network N/A Base case Change N/A N/A Generator IN MODELS N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A IN MODELS IN MODELS N/A N/A NOT IN MODELS IN MODELS N/A 3.2.4 Area Interchange Area interchange will be set to model firm and expected inter- and intra MISO transactions. A transaction workbook including OASIS data will be utilized to determine Area Interchange. Data needed to model transactions will include the source and sink areas, transaction MW amount, applicable model scenarios, start/end dates and an OASIS reference (Transmission Service Reservation) number or a Grandfathered Agreement (GFA) number if applicable (Expected transfers may not have OASIS or GFA information). This data is required to be provided by TOs in collaboration with their Balancing Authority. The LBA may submit the data instead of the control area Transmission Owner if MISO is notified via email by both parties to TAMModeling@misoenergy.org Transactions need to be confirmed by both transacting parties. MISO will post a workbook for review, edits, additions and deletions. Final cases are solved by enabling the PSS/E “ties + loads” interchange function. Method to collect transaction level data will be accomplished through a workbook. 3.2.5 Ratings Data owners are responsible for maintaining the ratings data for their facilities in MOD. While creating cases, facility ratings are selected as indicated below: Rate A=Normal Rate B=STE (emergency rating, the rating used in contingency analysis) Rate C=LTE (Long-Term Emergency Rating, not required) 3.2.6 Standard Case Effective Dates Effective dates are cutoffs that are used to identify projects that are applied to the corresponding model scenario as noted in Table 3-2. Therefore, all projects that have their expected in service date specified to be on or before the effective date are included in the corresponding model. Table 3-2: Standard Effective Dates Season MISO Standard Case Effective Date (MM/DD) Spring and Spring Light Load 04/15 Summer and Summer Shoulder 07/15 9 Fall 10/15 Winter 01/15 3.2.7 Modeling of Wind Farms Data should be submitted to allow wind farms to be modeled as a single equivalent machine with at least the following: Point of Interconnection Transformer (Medium to High voltage) Equivalent generator step-up transformer (Low to Medium voltage) Collector System Equivalent (transmission lines representing the equivalent impedance of the collector system) Wind Turbine Generator modeled at the appropriate low voltage (i.e. 690 V) WMOD3 and WPF4 populated with an appropriate value Interconnection Transmission Line POI Transformer High Voltage (i.e. 345 kV) Collector System Equivalent GSU Equivalent Mid Voltage (i.e. 34.5 kV) Wind Generator Low Voltage (i.e. 690 V) Plant Reactive Support Generator Reactive Support Figure 3-1: Single equivalent machine representation for wind farm Modeling multiple equivalent machines for a single wind farm is acceptable when trying to model: Different turbine types/manufactures Geographic diversity Explicit ownership Different development phases Bus numbers for buses shown in Figure 3-1 should be coordinated with the interconnecting TO. Specific wind output levels are required to be specified for the various scenarios in the BLG profile, as shown in Table 3-3. 3 4 Wind Machine Control Mode Wind Power Factor MISO 10 Table 3-3: Required Wind Output Scenario Wind Level Wind Unit Output (%) Summer Peak Capacity Credit Wind 14%* Summer Shoulder, Winter Peak Average Wind 40%* Fall, Spring, Light Load, Summer Shoulder High Wind 90% Light Load No Wind 0% *14% is used as capacity credit *40% is used as a proxy for average wind 3.2.8 Dispatch MISO uses a combination of generation dispatches for its NERC TPL analyses. Most models that are used for steady state analysis contain a control area level Network Resource dispatch. For implementing this dispatch, Network Resources in each control area are dispatched in economic order to meet the load, loss and interchange level from the area interchange workbook at the control area level. Light Load models use the dispatch submitted to Model On Demand. 3.2.9 Load Modeling It is desired that station service load have a consistent load ID across the MISO footprint so it is easily identifiable. As such, it is desired that station service load have a load ID of SS. If a legacy station service load ID is being used please communicate that to MISO via email to: TAMmodeling@misoenergy.org. Additionally the scalable load should also be easily identifiable. Therefore, the scalable load field should be populated as 1 if it is scalable and 0 if it is not. 3.2.10 Tie Lines MISO will maintain a tie-line workbook for its members’ ties with external (non-MISO) entities. The workbook format will be determined by the ERO/designee. The Power Flow Coordinator maintains a Master Tie Line Database. A tie line will not be represented in a particular power flow base case model unless both parties have agreed to include it. Tie lines between MISO entities need to be coordinated between both parties. MISO can facilitate dialogue between its members if that is desired. 3.3 Scenarios For each MTEP planning cycle MISO will develop a set of power flow cases as shown in Table 3-4. The scenarios developed could change from year to year based on MISO and member needs. However at a minimum those needed for TPL and MOD-032 compliance will be included. General descriptions of the scenarios are provided below: MISO 11 Winter Peak Load (WIN) – is defined as the winter peak demand expected to be served. Spring Light Load (SLL) - is defined as a typical early morning load level, modeling at or near minimum load conditions. Summer Peak Load (SUM) - is defined as the summer peak demand expected to be served. Summer Shoulder Load (SSH) - is defined as 70% to 80% of summer peak load conditions. Fall Peak Load (FAL) - is defined as typical fall peak load conditions. Table 3-4: Scenarios to be developed Model Spring Spring Summer Summer Fall Winter Year Light Load Shoulder Peak Peak 0 X X X 1 X X X X 2 X X X 5 X X X X 10 X X For example for the 2016 model series the model years would be 2016, 2017, 2018, 2021, 2026 3.4 Schedule The annual schedule power flow model development schedule is shown in Table 3-5. Specific dates will be supplied with the annual data request. Table 3-5: Power flow Development Schedule Task Estimated Completion GO Data Request August Transaction Data Request August GO Data Due September Transaction Data Due September TOs & LSEs submit initial data to MOD st Post 1 pass models to MTEP ftp site for review Members submit updates/corrections to MOD Post Final MTEP models Request Updates prior to MMWG submittal Send final models to ERO October December Dec-Jan March April June (Actual timeframe to be determined based on ERO schedule) 3.5 Power Flow Data Checks Once the power flow models are created, a set of data checks to flag potential issues with the data submitted will be performed by MISO. Section 10.1 provides a list of the quality checks MISO 12 performed. In addition to the data checks, a sample N-1 DC contingency screen is performed to assist with model review. Results of the data checks and sample contingency screens will be included along with each model posting. Data owners are required to submit corrected data in the time window specified in the model review request/notification. 3.6 MOD Training & Access 3.6.1 MOD Access Levels A brief description of the different access levels in MOD is provided below: Market Participant – Only has ability to access the MOD Base case Ratings Only - Can only view and submit equipment ratings. User – Can create and submit modeling data in MOD. Majority of data users. Local Process Manager – Review, approve and may submit information to MISO Process Manager MISO Process Manager – Reviews and accepts submittals (limited to MISO staff). MOD Administrator – Sets roles of MOD users (limited to MISO staff). Data submitters will require “User” level access in order to submit the necessary data. The diagram below shows the sequence of data from their submission to MOD through their implementation in models. Figure 3-6: Sequence of MOD Data Submission 3.6.2 Obtaining Access to MOD In order to gain access to MOD, each company must have a Universal NDA on file with MISO and each individual user is required to sign a Critical Energy Infrastructure Information (CEII) NDA. MISO Client Relations can assist in completing or verifying the NDAs. MISO Client Relations can be contacted via e-mail at clientrelations@misoenergy.org Once the appropriate NDAs are in place, the company should complete one of the following MOD access request forms: MISO 13 For access allowing submission of modeling data: - https://www.misoenergy.org/_layouts/miso/ecm/redirect.aspx?id=145068 For MOD base case read-only access (does not have ability to submit data to MOD): - https://www.misoenergy.org/_layouts/miso/ecm/redirect.aspx?id=145069 3.6.3 MOD Training MISO will generally conduct training on how to submit data through MOD annually in the Fall. Additional training sessions may be scheduled as needed. Current MOD training materials are available at: https://www.misoenergy.org/Library/Repository/Meeting%20Material/Stakeholder/Trainin g%20Materials/300%20Level%20Training/Level%20300%20%20Transmission%20Modeling%20Tools%20MOD.pdf File format excel workbooks and Model On Demand file examples are posted to aid in submittal of data to Model On Demand on the MTEP ftp site at the following location: /usr/users/mtepro/mtep/MOD-032 MISO 14 4 Dynamics Model Development 4.1 Data Format Dynamics modeling data needs to be submitted in the form of a Siemens PTI PSS/E dyr file. Dyr file submittals can be of just changes to your system from the existing dyr or of an entire representation of only your system in a dyr. Models are developed using the PSS/E software program. Data submitted must be compatible with the PSS/E version currently specified by MISO. Standard library models should be used to represent all active elements (generators, static VAR compensators, etc) whenever possible. If a user-written model (UDM) is being submitted, documentation and an object file or source code must be submitted along with the dyr file. The documentation must include the characteristics of the model including block diagrams, values and names for all model parameters, and a list of all state variables. Modeling data requests and notifications are sent to the Planning Subcommittee mailing list. Individuals can subscribe to the list at the following location: https://www.misoenergy.org/Pages/ListsSignup.aspx. 4.2 Level of Detail Dynamics simulations analyze the transient response of the power system following a disturbance. These simulations are in a timeframe of 0 to 20 seconds with a typical time step of ¼ cycle. As such it is necessary to develop a model that sufficiently represents the automatic response of all active elements to a disturbance on the power system. On an annual basis each data owner is required to submit the following model data: Dynamic models to represent approved future active elements such as generators, FACTS devices, or fast switching shunts Updates to existing dynamic models GOs and LSEs are expected to submit directly to MISO unless they have made arrangements with the interconnecting Transmission Owner to submit data on their behalf. If arrangements have been made, it must be communicated in writing to MISO at TAMModeling@misoenergy.org If the data has not changed since the last submission, a written confirmation that the data has not changed is sufficient. Such confirmation should be sent to MISO as the Planning Coordinator and the appropriate Transmission Planner. MISO correspondence should be sent by email to TAMModeling@misoenergy.org. MISO 15 4.2.1 Power Flow Representation The dynamics model will use a power flow model consistent with the steady-state model outlined in Section 3. If changes are required to the power flow data for dynamics they should be reflected in the steady-state power flow cases and the appropriate changes entered in MOD. 4.2.2 Dynamics Representation 4.2.2.1 Generators At a minimum, all generators with a nameplate greater than 20 MVA or a facility with an aggregated nameplate greater than 75 MVA must be modeled in detail (except for those meeting the exclusion criteria as specified in the NERC BES definition) and additionally Blackstart Resources identified in the Transmission Operator’s restoration plan. A detailed model of a generator must include: Generator Model Excitation System Model o May be omitted if unit is operated under manual excitation control Turbine-Governor Model o May be omitted if unit doesn’t regulate frequency Power System Stabilizer Model o May be omitted if device is not installed or not active Reactive Line Drop Compensation Model o May be omitted if device is not installed or not active Generators with detailed modeling must use a dynamic model from the Standard Generator Component Model List, specified in Section 5. If a suitable model is not on the standard list the data submitter may request a model be added to the standard list by providing MISO with a technical justification for doing so. Additions to the standard list will be handled on a case by case basis. Several legacy models have been omitted from the Standard Generator Component Model List since they can be directly converted to newer dynamic models with minimal effort and without changes to simulation results. The recommended conversions from a particular legacy model to a newer model are listed in Section 6. In instances where detailed dynamic modeling is unavailable, generic data may be used. Generators without detailed modeling will be netted with the load (set as a negative load). 4.2.2.2 Static VAR Systems & Synchronous Condensers Static VAR Systems (SVS) and synchronous condensers are reactive power devices that can vary the amount of reactive power supplied or absorbed within the simulated timeframe (0-20 seconds). These devices must be modeled in sufficient detail in order to simulate its expected behavior. If the reactive power device is modeled as a generator (for example a synchronous condenser) it should follow the guidelines in Section 4.2.2.1. MISO 16 4.2.2.3 HVDC All HVDC transmission facilities must be represented with a sufficiently detailed model to simulate its expected behavior. For future HVDC transmission facilities where exact design specifications are not known generic HVDC models should be used (such as CDC6). 4.2.2.4 Load The dynamic behavior of load must be modeled in sufficient detail to meet NERC TPL compliance obligations. The dynamic behavior of load can be specified on an aggregate (area/zone/owner) or individual bus level. Providing a specific dynamic load characteristic model or the motor load composition is acceptable. Loads with detailed characteristic modeling must use a dynamic model from the Standard Component Model List, specified in Section 5.9. If a desired model is not on the standard list the data submitter may request a model be added to the standard list by providing MISO with a technical justification for doing so. Additions to the standard list will be handled on a case by case basis. If a specific dynamic load characteristic model is not provided, the motor load composition of the load on a bus/area/zone or owner level is required in order to determine the appropriate dynamic representation. The composition of the load shall be defined as: Motor A – Small 3-Phase (i.e. compressor motors used in large air-conditioners and refrigerators) Motor B – Large 3-Phase (i.e. Fan Motor) Motor C – Medium 3-Phase (i.e. Pump Motor) Motor D – 1-Phase Air Conditioner Compressor Motor Electronic Load – Voltage Dependent Load Static Load – Frequency & Voltage Dependent Load Based on the composition of the load an appropriate dynamic representation will be developed using the composite load model (CMLD). Additional details on how the composite load model parameters will be developed are specified in Section 7. A walkthrough of how to determine the motor load composition based on the Residential/Commercial/Industrial/Agricultural composition of the load is also detailed in Section 7. 4.2.2.5 Protection Relays Generic protection relays are applied during the simulation that scan for bus voltages, out-ofstep conditions, and against generic protection zones for transmission lines. These generic protection relays only monitor system conditions. Table 4-1 shows the settings of the generic relays. Table 4-1: Generic Relay Settings Generic Relay Generic Transient Voltage Monitoring Generic Out-of-Step Monitoring Generic Distance Relay MISO Monitored Condition 0.7 ≤ Vbus ≤ 1.2 (12 cycles following the initiating event) Apparent Impedance > Line Impedance Circle A = 1.00 x Line Impedance Circle B = 1.25 x Line Impedance 17 Circle C = 1.50 x Line Impedance Equipment specific detailed protection relays may also be submitted at the discretion of the data owner; however, detailed protection relay models need to be submitted for: Voltage and frequency ride through capabilities of o Nuclear Facilities o Wind Farms Automatic action of Special Protection Schemes (SPS) 4.3 Scenarios For each MTEP planning cycle, MISO will develop a single dynamics data set to be used with the associated power flow models list in Table 4-2. The scenarios developed could change from year to year based on MISO and member needs. However at a minimum those needed for TPL and MOD-032 compliance will be included. Table 4-2: Power flow Scenarios Used for Dynamics Model Year 0 1 5 10 Light Load Summer Summer Winter Fall Peak Peak Shoulder Peak X X X X X X X* *Will be built if proposed material generation additions or changes occur in between years 5&10. If year 10 Summer Peak is required to be submitted to ERO designee and MISO has no material generation additions/changes, MISO will submit +5 Summer Peak dynamics. 4.4 Schedule The annual schedule for dynamics model development is shown in Table 4-3. Specific dates will be supplied with the annual data request. Table 4-3: Dynamics Development Schedule Task Estimated Completion MISO requests updated Dynamic data (dyr updates) April Create Initialized Pass 1 Dynamics Package Post Initialized Pass 1 Dynamics Package & provide output of sample set of disturbances Data Owners review and provide corrections Incorporate updates and develop Final Dynamics Package Post Final Dynamics Package April - May Dynamics Data submitted to ERO or its Designee MISO May June June July August (Actual timeframe to be determined based on 18 ERO schedule) 4.5 Dynamics Data Checks Once the dynamic models are created, a set of data checks to flag potential issues with the data submitted will be performed. Section 10.2 provides a list of the data quality checks performed. In addition to the data checks, a sample set of disturbances are run to assist in model review. Data owners are required to submit corrected model data in the time window specified in the model review request/notification. MISO 19 5 Standard Generator & Load Component Model List Please note that TSAT may not have a standard library model for all PSS/E or PSLF dynamic component model but still has the ability to automatically read and convert them into the appropriate TSAT format. Some models will be listed as “UDM” for TSAT, however; this should not be confused with the term “user-written model” or “UDM” used in the context of PSS/E or PSLF. 5.1 Generator Models PSS/E V33 PSLF V18 TSAT V12 Description CSTATT stcon UDM Static Condenser FACTS CSVGN1 vwscc SVC Type 1 SCR Controlled Static Var Source CSVGN3 vwscc SVC Type 1 SCR Controlled Static Var Source CSVGN5 vwscc SVC Type 2 SCR Controlled Static Var Source GENROE genrou DG0S2 GENROU genrou DG0S5 GENSAE gensal DG0S2 GENSAL gensal DG0S4 MISO Notes Not a direct conversion for PSLF Not a direct conversion for PSLF Not a direct conversion for PSLF If combined with STBSVC model will convert to SVC Type 3 in TSAT Round Rotor Generator with Exponential Saturation Round Rotor Generator with Quadratic Saturation Salient Pole Generator with Exponential Saturation Salient Pole Generator with Quadratic Saturation 20 5.2 Exciter Models PSS/E V33 ESDC1A ESDC2A DC3A DC4B ESAC1A ESAC2A ESAC3A ESAC4A ESAC5A ESAC6A AC7B AC8B ESST1A ESST2A ESST3A ESST4B ST5B ST6B ST7B ESAC8B PSLF V18 esdc1a esdc2a esdc3a esdc4b esac1a esac2a esac3a esac4a esac5a esac6a esac7b esac8b esst1a esst2a esst3a esst4b esst5b esst6b esst7b esac8b TSAT V12 EXC1 EXC1 UDM UDM EXC5 EXC6 EXC4 EXC30 EXC10 UDM UDM UDM EXC34 EXC7 EXC8 UDM UDM UDM UDM UDM Description 1992 IEEE Type DC1A 1992 IEEE Type DC2A 2005 IEEE Type DC3A 2005 IEEE Type DC4B 1992 IEEE Type AC1A 1992 IEEE Type AC2A 1992 IEEE Type AC3A 1992 IEEE Type AC4A 1992 IEEE Type AC5A 1992 IEEE Type AC6A 2005 IEEE Type AC7B 2005 IEEE Type AC8B 1992 IEEE Type ST1A 1992 IEEE Type ST2A 1992 IEEE Type ST3A 2005 IEEE Type ST4B 2005 IEEE Type ST5B 2005 IEEE Type ST6B 2005 IEEE Type ST7B Basler DECS EX2000 esac7b UDM EX2000 Excitation System EXAC2 exac2 EXC6 1981 IEEE Type AC2 EXAC3 exac3 EXC4 1981 IEEE Type AC3 EXST3 exst2 EXC7 1981 IEEE Type ST2 EXBAS - UDM EXPIC1 expic1 UDM SCRX scrx EXC30 Basler Static Voltage Regulator Feeding DC Proportional/integral Excitation Bus or solid fed SCR Bridge Excitation SEXS sexs EXC30 MISO Simplified Excitation Notes Prefer moving to newer AC8B Not a direct conversion in PSLF Prefer moving to newer ESAC2A Prefer moving to newer ESAC3A Prefer moving to newer ESST2A Only to be used for future machine where excitation system details are unknown Only to be used for future machine where excitation system details are unknown 21 5.3 Turbine/Governor Models PSS/E V33 DEGOV1 GAST GAST2A GASTWD PSLF V18 gast - TSAT V12 UDM GOV7 UDM UDM GFT8WN - UDM GGOV1 HYGOV ggov1 hygov UDM GOV20 IEEEG1 ieeeg1 GOV4 IEEEG2 ieeeg2 GOV22 IEEEG3 ieeeg3 GOV21 PIDGOV TGOV1 pidgov tgov1 UDM GOV6 TGOV3 tgov3 GOV4 WESGOV - GOV4 WSIEG1 ieeeg1 GOV4 MISO Description Woodward diesel governor Gas Turbine-governor Gas Turbine-governor Gas Turbine-governor Notes UDM Source Code available GE General purpose turbine-governor Hydro turbine-governor 1981 IEEE Type 1 Turbine-governor 1981 IEEE Type 2 Turbine-governor 1981 IEEE Type 3 Turbine-governor Hydro turbine and governor Steam Turbine-governor Modified IEEE Type 1 turbine-governor with fast valving Westinghouse digital governor for gas turbine 1981 IEEE Type 1 Turbine-governor with deadband & nonlinear valve gain 22 5.4 Turbine Load Controller Models PSS/E V33 LCFB1 PSLF V18 lcfb1 TSAT V12 UDM Description Turbine Load Controller Notes 5.5 Power System Stabilizer Models PSS/E V33 IEEEST IEE2ST PSS2A PSS2B PSS3B PSS4B PSLF V18 ieeest pss2a pss2b pss3b pss4b TSAT V12 PSS1 PSS12 PSS9 PSS9 UDM UDM STAB3 - PSS1 STAB4 - PSS12 Description 1981 IEEE PSS Dual Input PSS 1992 IEEE PSS2A 2005 IEEE PSS2B 2005 IEEE PSS3B 2005 IEEE PSS4B Power Sensitive Stabilizer Power Sensitive Stabilizer svcwsc SVC Type 3* Supplementary Signal for Static VAR System STBSVC Notes For TSAT & PSLF Embedded in SVC Model 5.6 Compensator Models PSS/E V33 IEEEVC - - REMCMP - - MISO PSLF V18 TSAT V12 Description 1981 IEEE Voltage Compensating model Notes Embedded in PSLF generator record and TSAT exciter model Remote Bus Voltage Signal 23 5.7 Wind Models PSS/E V33 WT1G1, WT12T1, WT12A1 WT2G1, WT2E1, WT12T1, WT12A1 WT3G2, WT3E1, WT3T1, WT3P1 WT4G1, WT4E1, PSLF V18 wt1g, wt1t,wt1p TSAT V12 WGNA, WGNAT, WGNAE WGNB, WGNBT, WGNBE Description Generic Type 1 WTG wt3g, wt3e, wt3t, wt3p WGNBC, WGNBT, WGNBE Generic Type 3 WTG wt4g, wt4e, wt4t, wt4p Generic Type 4 WTG - WGND, WGNDT, WGNBE - W4G2U, W4E2U SWTVS4 - - Siemens WTG UDM SWTDD4 - - Siemens WTG UDM wt2g, wt2e, wt2t, wt2p Notes Generic Type 2 WTG Updated Generic Type 4 WTG Includes additional parameters to model Siemens WTG Necessary only if Siemens Weak Grid Option installed Necessary only if Siemens Weak Grid Option installed 5.8 PV Models PSS/E V33 PSLF V18 TSAT V12 Description Notes No standard model currently available across software platforms 5.9 Load Characteristics Models Note: In PSS/E all Load characteristic models may be specified on the Bus, Owner, Zone, or Area basis. PSS/E V33 ACMTxxU1 PSLF V18 ld1pac TSAT V12 MOT1PH CIM5xx - MOT1LI MISO Description 1-Phase Air Conditioner Motor Model 3-Phase Induction Motor Model Notes 24 CIM6xx - MOT1LI CIMWxx motor1 MOT1LI CLODxx CMLDxxU1 IEELxx LDFRxx cmpldw xlwscc LOADX LOADX LOADX Internally converted ZIP MISO 3-Phase Induction Motor Model WECC 3-Phase Induction Motor Model Complex Load Model Composite Load Model IEEE Load Model Load Frequency Model Constant impediance, current & power With reference to TPL-001-4 section 2.4.1, “An aggregate System Load model which represents the overall dynamic behavior of the Load is acceptable” , these models cannot be used solely to represent an entire area, as they are static load models. They can be used in conjunction with other dynamic load models or induction motor models. 25 6 Converting Legacy to Newer Models MISO has developed and tested conversion methods for moving the legacy models to their new equivalents. These conversions can be found at the following location: - https://www.misoenergy.org/_layouts/MISO/ECM/Redirect.aspx?ID=173635 6.1 Generators Not Applicable 6.2 Exciters ESAC8B AC8B EXAC1 ESAC1A EXAC1A ESAC1A EXAC2 ESAC2A EXAC3 ESAC3A EXAC4 ESAC4A EXDC2 ESDC2A EXST1 ESST1A EXST2 ESST2A EXST2A ESST2A EXST3 ESST3A IEEET1 ESDC1A IEEET2 ESDC2A IEEET3 ESST2A IEEET5 DC3A IEEEX1 ESDC1A IEEEX2 ESAC5A IEEEX4 DC3A IEEX2A ESDC2A UREXAC EX2000 6.3 Turbine/Governors IEESGO IEEEG1 ETSIG2 IEEEG1 UGGOV1 GGOV1 6.4 Turbine Load Controller Not Applicable MISO 26 6.5 Power System Stabilizer STAB1 IEEEST 6.6 Compensator COMP IEEEVC 6.7 Wind A1530X WT3G2 C93GEN WT4G1 GEWTG1 WT3G2 (or WT4G1 if Full Converter) GEWTG2 WT3G2 (or WT4G1 if Full Converter) SWTVS4 W4G2U WT3G1 WT3G2 WT3G WT3G2 6.8 PV Not Applicable MISO 27 7 Composite Load Model The composite load model was developed through industry collaboration led by the efforts of the Western Electricity Coordinating Council (WECC) Load Model Task Force (LMTF). The composite load model has since been implemented into the various commercially available software tools. Figure 7-1 provides a diagram of the composite load model. Please refer to the WECC Report “Composite Load Model for Dynamic Simulations”5 for additional information about the composite load model. Motor A – 3 Phase Motor B – 3 Phase Distribution Transformer Equivalent Distribution Feeder Equivalent Motor C – 3 Phase Motor D – 1 Phase High Voltage System Bus (i.e. 115 kV) Electronic Low Voltage Distribution Bus (i.e. 13.8 kV) Static Figure 7-1: Composite Load Model 5 https://www.wecc.biz/_layouts/15/WopiFrame.aspx?sourcedoc=/Reliability/WECC%20MVWG%20Load% 20Model%20Report%20ver%201%200.pdf&action=default&DefaultItemOpen=1 MISO 28 7.1 Parameter Derivation Based on Load Composition The composite load model has 132 different parameters. The majority of these parameters are used to define the characteristics and behavior of the 6 main components of the model, which are listed below: Motor A – Small 3-Phase (i.e. compressor motors used in large air-conditioners and refrigerators) Motor B – Large 3-Phase (i.e. Fan Motor) Motor C – Medium 3-Phase (i.e. Pump Motor) Motor D – 1-Phase Air Conditioner Compressor Motor Electronic Load – Voltage Dependent Load Static Load – Frequency & Voltage Dependent Load Table 7-1 provides example percentages of load composition for the different components of load. Table 7-1-1: Sample Summer Peak Load Composition Based on R/C/I/A Motor A Motor B Motor C Motor D Electronic Static Residential 8% 7% 2% 34% 15% 34% Commercial 12% 10% 4% 25% 18% 31% Industrial 13% 22% 16% 0% 27% 22% Agricultural 10% 20% 22% 8% 10% 30% Table 7-1-2: Sample Shoulder Load Composition Based on R/C/I/A Motor A Motor B Motor C Motor D Electronic Static Residential 8% 7% 2% 25% 19% 39% Commercial 12% 10% 4% 20% 23% 31% Industrial 13% 22% 16% 0% 27% 22% Agricultural 10% 20% 22% 8% 10% 30% Table 7-1-3: Sample Light Load Composition Based on R/C/I/A Motor A Motor B Motor C Motor D Electronic Static Residential 10% 8% 2% 0% 40% 40% Commercial 12% 10% 4% 5% 38% 31% Industrial 13% 22% 16% 0% 27% 22% Agricultural 10% 20% 25% 5% 10% 30% Table 7-1-4: Sample Winter Peak Composition Based on R/C/I/A Motor A Motor B Motor C MISO Residential 10% 7% 2% Commercial 12% 10% 4% Industrial 13% 22% 16% Agricultural 15% 20% 15% 29 Motor D Electronic Static 0% 35% 46% 0% 34% 40% 0% 27% 22% 0% 10% 40% Since load components are defined as fractions of the total load, mixtures of Residential/Commercial/Industrial/Agricultural are handled by summing the weighted fraction as shown in Table 7-2. Table 7-2: Derivation of Load Composition Based on R/C/I/A in Table 7-1-1 PSS/E CON Description Value Based on R/C/I/A Mix J+18 Fma, Motor A Fraction Fma = (0.08*R+0.12*C+0.13*I+0.10*A) J+19 Fmb, Motor B Fraction Fmb = (0.07*R+0.10*C+0.22*I+0.18*A) J+20 Fmc, Motor C Fraction Fmc = (0.02*R+0.04*C+0.16*I+0.22*A) J+21 Fmd, Motor D Fraction Fmd = (0.34*R+0.25*C+0.0*I+0.10*A) J+22 Fel, Electronic Load Fraction Fel = (0.15*R+0.18*C+0.27*I+0.10*A) Note: Static Load fraction is defined as remainder of the load in order to get to 100% 7.2 Example Composite Load Model Based on Load Composition The PSSE dyr entry for composite load model has the following structure: I, 'USRLOD', LID, 'CMLDxxU1', 12, IT, 0, 132, 27, 146, 48, CON(J) to CON(J+131) / Where: Model suffix "XX" Corresponding "IT" Description Corresponding "I" Description BL 1 Bus number OW 2 Owner number ZN 3 Zone number AR 4 Area number AL 5 0 Below is an example of how the composite load fractions will be calculated based on a provided load composition. Given the load composition for area 1 is: Residential – 40% Commercial – 30% Industrial – 20% Agricultural – 10% Thus: MISO Fma = (0.08*R+0.12*C+0.13*I+0.10*A) = (0.08*0.4+0.12*0.3+0.13*0.2+0.10*0.1) = 0.104 Fmb = (0.07*R+0.10*C+0.22*I+0.18*A) = (0.07*0.4+0.10*0.3+0.22*0.2+0.18*0.1) = 0.12 30 Fmc = (0.02*R+0.04*C+0.16*I+0.22*A) = (0.02*0.4+0.04*0.3+0.16*0.2+0.22*0.1) = 0.074 Fmd = (0.34*R+0.25*C+0.0*I+0.10*A) = (0.34*0.4+0.25*0.3+0.0*0.2+0.10*0.1) = 0.221 Fel = (0.15*R+0.18*C+0.27*I+0.10*A) = (0.15*0.4+0.18*0.3+0.27*0.2+0.10*0.1) = 0.178 The DYR entry would be: 1 MISO 'USRLOD' * 132 0.0 1.0 1.0 0.0 0.221 0.95 0.0 0.0 0.12 0.0 999.0 999.0 0.19 2.0 999.0 999.0 0.19 2.0 999.0 999.0 1.0 0.0 12.0 0.2 0.4 1.3 5.0 'CMLDARU1' 27 0.01 1.0 1.0 0.0 0.178 2.0 2.0 3.0 0.104 0.6 0.4 3.0 0.14 0.6 0.4 3.0 0.14 0.6 0.4 0.033 0.97 0.0 3.2 0.6 0.6 0.0 / 12 146 0.001 0.0 1.0 0.104 0.9 0.615 -0.5 0.85 .095 0.1 0.1 0.75 0.2 0.1 0.1 0.75 0.2 0.1 0.1 0.4 0.6 1.0 11.0 1.0 0.5 0.0 4 48 0.0 1.0 0.0 0.12 0.6 1.0 1.0 0.04 0.0021 0.15 0.15 0.03 0.0026 0.15 0.15 0.03 0.0026 0.15 0.15 0.02 0.124 6.0 2.5 -3.3 10.0 0.2 0 0.0 0.0 1.0 0.0 0.074 0.4 0.38 1.5 1.8 0.1 999.0 999.0 1.8 0.15 999.0 999.0 1.8 0.15 999.0 999.0 0.02 0.114 2.0 0.86 0.5 0.7 0.0 31 8 Short Circuit Model Development MISO will not maintain a short-circuit model database, but will pass short-circuit data through to ERO designee upon request. Upon ERO designee providing a schedule for interconnectionwide short-circuit model development, MISO as the Planning Coordinator will send a notification and subsequent data request to Transmission Owners for short-circuit data to be submitted in PSS/e compatible format. Short-circuit model data should not contain equivalent sources for systems external to Transmission Owner’s system. Data will be due to MISO at least 5 business days before short-circuit data is due to ERO designee. MISO 32 9 MOD-032-1 – Attachment 1 The table, below, indicates the information that is required to effectively model the interconnected transmission system for the Near‐Term Transmission Planning Horizon and Long‐Term Transmission Planning Horizon. Data must be shareable on an interconnection-wide basis to support use in the Interconnection‐wide cases. A Planning Coordinator may specify additional information that includes specific information required for each item in the table below. Each functional entity1 responsible for reporting the respective data in the table is identified by brackets “[functional entity]” adjacent to and following each data item. The data reported shall be as identified by the bus number, name, and/or identifier that is assigned in conjunction with the PC, TO, or TP. steady-state (Items marked with an asterisk indicate data that vary with system operating state or conditions. Those items may have different data provided for different modeling scenarios) 1. 2. 3. Each bus [TO] a. nominal voltage b. area, zone and owner Aggregate Demand6 [LSE] a. real and reactive power* b. in-service status* Generating Units7 [GO, RP (for future planned resources only)] a. real power capabilities - gross maximum and minimum values b. reactive power capabilities maximum and minimum values at real power capabilities in 3a above c. station service auxiliary load for normal plant configuration (provide data in the same manner as that required for aggregate Demand under item 2, above). d. regulated bus* and voltage set point* (as typically provided dynamics (If a user-written model(s) is submitted in place of a generic or library model, it must include the characteristics of the model, including block diagrams, values and names for all model parameters, and a list of all state variables) 1. Generator [GO, RP (for future planned resources only)] 2. Excitation System [GO, RP(for future planned resources only)] 3. Governor [GO, RP(for future planned resources only)] 4. Power System Stabilizer [GO, RP(for future planned resources only)] 5. Demand [LSE] 6. Wind Turbine Data [GO] 7. Photovoltaic systems [GO] 8. Static Var Systems and FACTS [GO, TO, LSE] 9. DC system models [TO] 10. Other information requested by the Planning Coordinator or Transmission Planner necessary for modeling purposes. [BA, GO, LSE, TO, TSP] short circuit 1. Provide for all applicable elements in column “steady-state” [GO, RP, TO] a. Positive Sequence Data b. Negative Sequence Data c. Zero Sequence Data 2. Mutual Line Impedance Data [TO] 3. Other information requested by the Planning Coordinator or Transmission Planner necessary for modeling purposes. [BA, GO, LSE, TO, TSP] 6 For purposes of this item, aggregate Demand is the Demand aggregated at each bus under item 1 that is identified by a Transmission Owner as a load serving bus. An LSE is responsible for providing this information, generally through coordination with the Transmission Owner. 7 Including synchronous condensers and pumped storage. MISO 33 by the TOP) machine MVA base generator step up transformer data (provide same data as that required for transformer under item 6, below) g. generator type (hydro, wind, fossil, solar, nuclear, etc) h. in-service status* AC Transmission Line or Circuit [TO] a. impedance parameters (positive sequence) b. susceptance (line charging) c. ratings (normal and emergency)* d. in-service status* DC Transmission systems [TO] Transformer (voltage and phaseshifting) [TO] a. nominal voltages of windings b. impedance(s) c. tap ratios (voltage or phase angle)* d. minimum and maximum tap position limits e. number of tap positions (for both the ULTC and NLTC) f. regulated bus (for voltage regulating transformers)* g. ratings (normal and emergency)* h. in-service status* Reactive compensation (shunt capacitors and reactors) [TO] a. admittances (MVars) of each capacitor and reactor b. regulated voltage band limits* (if mode of operation not fixed) c. mode of operation (fixed, discrete, continuous, etc.) d. regulated bus* (if mode of operation not fixed) e. in-service status* Static Var Systems [TO] a. reactive limits b. voltage set point* c. fixed/switched shunt, if applicable d. in-service status* Other information requested by the Planning Coordinator or Transmission Planner necessary for modeling purposes. [BA, GO, LSE, TO, TSP] e. f. 4. 5. 6. 7. 8. 9. MISO 34 10 Data Checks 10.1 Power Flow Data Checks Name Data Checked Bus Voltage Blank Voltage Fields Machines on Code 1 Buses Buses Buses Buses; Generators Buses; Generators Buses; Generators Generators Including off-line generators Generators Including off-line generators Generators with STAT = 1 & Bus IDE=2 or 3 Generators Generators Online Machines on Code 4 Buses Code 2 Buses Without Machines Unrealistic PMAX and PMIN Unrealistic QMAX and QMIN PGEN Outside Range Non-positive RMPCT GTAP Out Of Range CNTB Errors Small Voltage Band Shunts Missing Block 1 Steps Transformer MAX below MIN Transformer Default R Transformer Default V Small Voltage Band Transformer Small Transformer Step Size MISO Switched Shunts; Generators; Transformers with COD1 = 1 Switched Shunts Switched Shunts 2-Winding Transformers with COD1 ≠ 0 2-Winding Transformers with COD1 ≠ 0 2-Winding Transformers with COD1 ≠ 0 All Transformers with COD1 = 1 Transformers Conditions Flagged Existing TO planning criteria Blank BASKV field Generator at bus with IDE = 1 Machine with STATUS = 1 at bus with IDE = 4 No generator at bus with IDE = 2 PMAX < PMIN, PMAX > 2000, PMIN < -1000 QMAX < QMIN, QMAX > 1000, QMAX < -1000 PGEN > PMAX, PGEN < PMIN RMPCT ≤ 0 GTAP > 1.1, GTAP < 0.9 Conflicting voltage objectives VSWHI – VSWLO < 0.0005 Missing Block 1 steps VMA1 ≤ VMI1, RMA1 ≤ RMI1 RMA1 = 1.5 and RMA2 = 0.51 VMA1 = 1.5 and VMA2 = 0.51 VMA – VMI < 2.0 × Step Size 0.015625 < Step Size < 0.00625 35 Name Data Checked Max or Min at 0 2-Winding Transformers with COD1 ≠ 0 Branch Issues Branches; 2-Winding Transformers Rating Errors Branches; Transformers 3 Winding Rating Errors 3-Winding Transformers3 Branch Overloads Islands Branches; Transformers Buses Unrealistic MBASE Generators Unrealistic ZSOURCE Generators Machines Missing GSU Machines at buses ≥ 50 kV Branches, Transformers Branches, Transformers Generators Open ended branches Branches to different bus voltages Wind units modeled at high voltage buses Ensure WMOD is populated for wind units modeled with library models Conditions Flagged RMA1 = 0, RMI1 = 0, VMA1 = 0, VMI1 = 0 Branches: R > |X| Transformers: R1-2 > |X1-2| High/Low Reactance, Charging Issues RATEB < RATEA, RATEA = 0, RATEB = 0 RATEB < RATEA, RATEA = 0, RATEB = 0 Branch loading above 100% of RATEA or RATEB Buses with IDE 1 or 2 not connected to a bus with IDE = 3 MBASE < PMAX, MBASE = 100 RSOURCE = 0 & XSOURCE = 1, RSOURCE = 1 & XSOURCE = 1, RSOURCE > XSOURCE Implicit GSU not specified Branch with STATUS = 1 connected to bus with IDE = 4 Branches between buses with different bus voltages Wind units that are modeled on buses 10kV or higher WMOD 10.2 Dynamics Data Checks Models Checked MISO Data Checked Conditions Flagged All Gen Model with inertia defined as H H H=0 All Gen Model with S(1.0) S(1.0) S(1.0) <0 All Gen Model with S(1.2) S(1.2) S(1.2) <0 All Gen Model with S(1.0) and S(1.2) S(1.0) S(1.0) > S(1.2) All Gen/Exciter Model with S(E1) S(E1) S(E1) < 0 36 Models Checked MISO Data Checked Conditions Flagged All Gen/Exciter Model with S(E2) S(E2) S(E2) < 0 All Gen/Exciter Model with S(E1) and S(E2) S(E1) S(E1) > S(E2) if E1 < E2 All Gen/Exciter Model with S(E1) and S(E2) S(E1) S(E1) < S(E2) if E1 > E2 All Gen Models with reactance/transient reactance defined as Xd and X'd in D axis Xd Xd <= X'd All Gen Models with transient reactance/sub-transient reactance defined as X'd and X''d in D axis X'd X'd <= X''d All Gen Models with sub-transient reactance/leakage reactance defined as X''d and XL in D axis X''d X''d <= XL All Gen Models with reactance/transient reactance defined as Xq and X'q in Q axis Xq Xq <= X'q All Gen Models with transient reactance/sub-transient reactance defined as X'q and X''q in Q axis X'q X'q <= X''d (X''d=X''q) All Gen Models with reactance/transient reactance defined as X and X' X X <= X' All Gen Models with transient reactance/sub-transient reactance defined as X' and X'' X' X' <= X'' if X''/=0 and T''/=0 All Gen Models with sub-transient reactance/leakage reactance defined as X'' and XL X'' X'' <= XL if X''/=0 and T''/=0 All Gen Models with transient reactance/leakage reactance defined as X' and XL X' X' <= XL if X''=0 or T'=0 37 11 Entity Lists A detailed list of NERC Compliance Registry is available at: http://www.nerc.com/pa/comp/Pages/Registration-and-Certification.aspx. A MISO membership listing is available at: https://www.misoenergy.org/StakeholderCenter/Members/Pages/Members.aspx. MISO 38 Appendix 1 Transmission Planner Compliance Pursuant to requirement R1 of MOD-032-1, MISO as a NERC Planning Coordinator (PC), and its NERC Transmission Planners (TPs) have jointly developed modeling data requirements and reporting procedures for MISO’s planning area. Transmission Planners that have participated in the development of this document are as follows. Transmission Planner Transmission Planner Participant ALLETE, Inc. (for its operating Ruth R. Pallapati division Minnesota Power) Ameren Services Company Jason Genovese American Transmission Curtis Roe Company, LLC Robert Krueger Big Rivers Electric Tim Curtis Corporation Cedar Falls Utilities Ken Kagy Central Iowa Power William Sondermann Cooperative City Of Ames Electric Lyndon Cook Services City of Columbia, MO Armin Karabegovic City of Lansing by its Board of Jamal Ahmed Water and Light Robert Tidd City Water, Light & Power Chris Daniels (Springfield, Illinois) Steve Rose Cleco Power LLC Terry Whitmore Chris Thibodeaux Ian Gray Dairyland Power Cooperative Steve Porter Duke Energy Corporation Phillip C. Briggs East Texas Electric Claudiu Cadar Cooperative, Inc. John Chiles Jason Shook (GDS Associates) Entergy William Hamilton Peng Yu Melinda Montgomery Great River Energy Patrick Quinn Hoosier Energy Rural Electric Matt Fields Cooperative, Inc. Indianapolis Power & Light Mark Kemper Company Robert Grubb Brad Williams International Transmission Michael C. Hamlin Company (d/b/a ITC Shalini Gupta MISO 39 Transmission Planner Transmission) ITC Midwest Lafayette Utilities System Michigan Electric Transmission Company, LLC MidAmerican Energy Company Minnkota Power Cooperative Muscatine Power & Water (Board Of Water, Electric & Communications) Montana Dakota Utilities Northern Indiana Public Service Company Otter Tail Power Company Prairie Power, Inc. Rochester Public Utilities South Mississippi Electric Power Association Southern Illinois Power Cooperative Southern Indiana Gas & Electric Company (Vectren) Southern Minnesota Municipal Power Agency Wolverine Power Supply Cooperative, Inc. Xcel Energy MISO Transmission Planner Participant Mike Hamlin Josh Grindeland (ITC Holdings Corp.) Hunter Boudreaux Mike Hamlin Shalini Gupta (ITC Holdings Corp.) Daniel Rathe Will Lovelace Lewis Ross Omer Vejzovic Shawn Heilman Lynn A. Schmidt Denise Keys Karl Kohlrus Scott Nickels Jason Goar Jeff Jones Larry Rogers Mark Rose Patrick Egan Rick Koch Tyler Bruning Jason Espeseth 40