USG Design Studio LEED Report Tool

advertisement

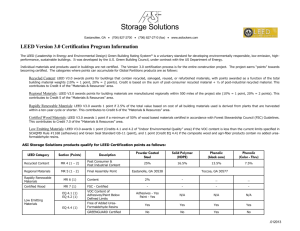

LEED Report 6/3/2010 Project Name: Created By: Project Location: Firm/Company Name: This document contains sustainability information for the following USG product(s): •Specialty Ceiling Systems Billo 3-D ceiling panel, C2 Paired Compasso, steel, Cadre sculpted ceiling panel, Celebration aluminum panel, Celebration steel suspension system, Compasso (10" & 12" painted aluminum), Compasso (2 1/4", 4", 6" & 8" painted steel), Compasso Slim, aluminum, Curvatura Diamondflex steel panel, Curvatura Lexan® panel, Curvatura aluminum panel, Curvatura steel suspension system and trim, Geometrix aluminum panel, GridWare, steel suspension, Libretto aluminum panel, Libretto profile trim and suspension, steel, Panz aluminum panels, Paraline aluminum pans, Quadra sculpted ceiling panel, Topo Lexan® panel, Translucents, FRP panel, Translucents, Lexan® panel, Translucents, PETG panel, Transparencies acrylic panel, True Wood ceiling panel, WireWorks steel panel LEED® is a guideline for building solutions established by the USGBC – Products are NOT “LEED certified”, however they can assist in obtaining LEED credits/points for a project. USG Corporation is a founding member of the U.S. Green Building Council. LEED Report 6/3/2010 Specialty Ceilings The following lists several LEED® prerequisites and information about the USG product you are specifying that may assist you in obtaining LEED credits. Billo 3-D ceiling panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (0%) Material Cost x material cost = Total Combined Value 0 x material cost US produced virgin polycarbonate raw material, manufactured in Franklin, WI C2 Paired Compasso, steel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (25%) Material Cost x material cost = Total Combined Value 0.125 x material cost US and foreign steel, manufactured in Westlake, OH Cadre sculpted ceiling panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% MR 5.1 & 5.2; Regional Tijuana, MX Pre-Consumer + 1/2 (0%) Material Cost x material cost = Total Combined Value 0 x material cost Materials Celebration aluminum panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 68% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (22%) Material Cost x material cost US aluminum, manufactured in Oakville, ON, Canada = Total Combined Value 0.79 x material cost LEED Report 6/3/2010 Specialty Ceilings The following lists several LEED® prerequisites and information about the USG product you are specifying that may assist you in obtaining LEED credits. Celebration steel suspension system Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (25%) Material Cost x material cost = Total Combined Value 0.125 x material cost US and foreign steel, manufactured in Westlake, OH Compasso (10" & 12" painted aluminum) Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 68% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (22%) Material Cost x material cost = Total Combined Value 0.79 x material cost US aluminum, manufactured in Oakville, ON, Canada Compasso (2 1/4", 4", 6" & 8" painted steel) Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (25%) Material Cost x material cost = Total Combined Value 0.125 x material cost US and foreign steel, manufactured in Westlake, OH Compasso Slim, aluminum Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer Pre-Consumer Material Cost Total Combined Value 0% MR 5.1 & 5.2; Regional Materials + 1/2 (0%) x material cost Virgin aluminum, manufactured in City of Industry, CA = 0 x material cost LEED Report 6/3/2010 Specialty Ceilings The following lists several LEED® prerequisites and information about the USG product you are specifying that may assist you in obtaining LEED credits. Curvatura Diamondflex steel panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (25%) Material Cost x material cost = Total Combined Value 0.125 x material cost US and foreign steel, manufactured in Vernon Hills, IL Curvatura Lexan® panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (0%) Material Cost x material cost = Total Combined Value 0 x material cost Manufactured in Coburg, ON, Canada Curvatura aluminum panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 68% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (22%) Material Cost x material cost = Total Combined Value 0.79 x material cost US aluminum, manufactured in Oakville, ON, Canada Curvatura steel suspension system and trim Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% Pre-Consumer + 1/2 (25%) Material Cost x material cost = Total Combined Value 0.125 x material cost MR 5.1 & 5.2; Regional Materials US and foreign steel, manufactured in Westlake, OH LEED Report 6/3/2010 Specialty Ceilings The following lists several LEED® prerequisites and information about the USG product you are specifying that may assist you in obtaining LEED credits. Geometrix aluminum panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 68% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (22%) Material Cost x material cost = Total Combined Value 0.79 x material cost US aluminum, manufactured in Oakville, ON, Canada GridWare, steel suspension Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (25%) Material Cost x material cost = Total Combined Value 0.125 x material cost US and foreign steel, manufactured in Westlake, OH Libretto aluminum panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 68% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (22%) Material Cost x material cost = Total Combined Value 0.79 x material cost US aluminum, manufactured in Oakville, ON, Canada Libretto profile trim and suspension, steel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer Pre-Consumer Material Cost Total Combined Value 0% MR 5.1 & 5.2; Regional Materials + 1/2 (25%) x material cost US and foreign steel, manufactured in Westlake, OH = 0.125 x material cost LEED Report 6/3/2010 Specialty Ceilings The following lists several LEED® prerequisites and information about the USG product you are specifying that may assist you in obtaining LEED credits. Panz aluminum panels Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 68% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (22%) Material Cost x material cost = Total Combined Value 0.79 x material cost US aluminum, manufactured in Oakville, ON, Canada Paraline aluminum pans Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 68% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (22%) Material Cost x material cost = Total Combined Value 0.79 x material cost US and foreign aluminum, manufactured in Westlake, OH Quadra sculpted ceiling panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (0%) = Total Combined Value 0 x material cost = Total Combined Value 0 x material cost Material Cost x material cost Tijuana, MX Topo Lexan® panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% Pre-Consumer + 1/2 (0%) Material Cost x material cost MR 5.1 & 5.2; Regional Materials US produced virgin polycarbonate raw material, manufactured in Franklin, WI LEED Report 6/3/2010 Specialty Ceilings The following lists several LEED® prerequisites and information about the USG product you are specifying that may assist you in obtaining LEED credits. Translucents, FRP panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% Pre-Consumer + 1/2 (0%) = Total Combined Value 0 x material cost = Total Combined Value 0 x material cost Material Cost x material cost MR 5.1 & 5.2; Regional Materials Translucents, Lexan® panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (0%) Material Cost x material cost US produced virgin polycarbonate raw material, manufactured in Franklin, WI Translucents, PETG panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% Pre-Consumer + 1/2 (40%) Material Cost x material cost = Total Combined Value 0.2 x material cost MR 5.1 & 5.2; Regional Materials Transparencies acrylic panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% MR 5.1 & 5.2; Regional Pre-Consumer + 1/2 (0%) Manufactured in Westlake, OH Material Cost x material cost = Total Combined Value 0 x material cost Materials LEED Report 6/3/2010 Specialty Ceilings The following lists several LEED® prerequisites and information about the USG product you are specifying that may assist you in obtaining LEED credits. True Wood ceiling panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 0% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (97%) Material Cost x material cost = Total Combined Value 0.485 x material cost Core (97%) from Bennettsville, SC WireWorks steel panel Possible LEED Credit: MR 4.1 & 4.2; Recycled Content (% by weight) Post-Consumer 80% MR 5.1 & 5.2; Regional Materials Pre-Consumer + 1/2 (20%) Material Cost x material cost US and foreign steel, manufactured in Chicago, IL = Total Combined Value 0.9 x material cost LEED Report 6/3/2010 Test Protocols & Definitions Recycled Content (Post-Consumer & Post-Industrial) per Federal Trade Commission Environmental Marketing Guides. Recycledcontent products may contain some pre-consumer waste, some post-consumer waste or both. A product does not have to contain 100 percent recovered materials to be considered "recycled," but the higher the percentage of recycled content, the greater the amount of waste that is diverted from disposal. Post-Industrial (Pre-Consumer) materials are generated by manufacturers and processors, and may consist of scrap, trimmings and other by-products that were never used in the consumer market. Post-Industrial and Pre-Consumer are one in the same under the USGBC LEED_ rating systems. Post-Consumer material is an end product that has completed its life cycle as a consumer item and would otherwise have been disposed of as a solid waste. Post-consumer materials include recyclables collected in commercial and residential recycling programs, such as office paper, cardboard, aluminum cans, plastics and metals. LR (Light Reflectance) tested per ASTM C1477 NRC (Noise Reduction Coefficient) tested per ASTM C423 CAC (Ceiling Attenuation Class) tested per ASTM 1414 TVOC (Total Volatile Organic Compound) emission measured per ASTM D 5116, State of Washington allows for 500 ug/m3 CHPS (Collaborative for High Performance Schools) follow EPA Section 01350 for VOC emission and determination on PASS. Formaldehyde emissions measured during CHPS testing per Section 01350, for most products CHPS allows 13.5 ppb & state of Washington allows for 50 ppb. Zero emissions is defined as the quantity less than test chamber background concentrations as required by Section 3.8.4.2 of the "Standard Practice for the Testing of Volatile Organic Emissions from Various Sources Using Small-Scale Environmental Chambers, Supercedes previous versions of small-scale environmental chamber testing portion of California Specification 01350, July 15, 2004." Section 3.8.4.3 states "Background concentrations in the empty chamber ventilated at 1.0 air changes per hour shall not exceed 2 _g m-3 for any individual VOC, and 25 _g m-3 for TVOC." LEED Report 6/3/2010 LEED Credits LEED® is a guideline for building solutions established by the USGBC – Products are NOT “LEED certified”, however they can assist in obtaining LEED credit/points for a project. Energy & Atmosphere EA Credit 1 – Optimize Energy Performance High light reflectance (LR) of ceiling materials can reduce required luminaires of design space as required per ASHRAE and reduce the number of light fixtures needed, curbing energy consumption. Materials & Resources MR Credit 2 – Construction Waste Management: Divert From Disposal 2.1 – Divert 50% of project waste (by weight) from landfill 2.2 – Divert another 25% of project waste (by weight) from landfill MR Credit 3 – Materials Reuse Products may contain synthetic material and metal ceilings/components may include recycled aluminum 3.1 – 5% of total materials use salvaged, refurbished, or reused materials (based on cost) 3.2 – 10% of total materials use salvaged, refurbished, or reused materials (based on cost) MR Credit 4 – Recycled Content 4.1 – 10% of project materials’ value (Post-Consumer + _ Post-Industrial) 4.2 – 20% of project materials’ value (Post-Consumer + _ Post-Industrial) MR Credit 5 – Local/Regional Materials: Extracted, Processed & Manufactured Regionally 5.1 – 10% of raw materials for above products obtained within 500 miles 5.2 – 20% of raw materials for above products obtained within 500 miles MR Credit 6 – Rapidly Renewable Materials Products may contain corn/ wheat starch binders, renewable alternatives to petroleum-based binders Indoor Environmental Quality EQ Credit 4 – Low-Emitting Materials 4.1, 4.2, 4.3, 4.4 – Products emit no formaldehyde or only a very low amount EQ Credit 8 – Daylight and Views 8.1, 8.2 – High LR can improve the quality and quantity of natural light by enhancing indirect lighting EQ Credit 9 – Enhanced Acoustical Performance Products used in tested assemblies may reduce sound transmission in spaces EQ Credit 10 – Mold Prevention Products may contain ingredients that reduce the potential growth of mold Innovation ID Credit 1 – Innovation Exceptional performance above LEED requirements can be awarded extra points LEED Report 6/3/2010 Resources USG www.usg.com www.usgdesignstudio.com www.sustainableceilings.com Customer Service: (800) 950-3839 OTHER http://www.usgbc.org http://www.uli.org http://www.chps.net http://www.chps.net/manual/lem_table.htm http://www.ashrae.org/ http://www.scscertified.com For additional information or assistance, please contact: Your local USG architectural rep or USG4YOU at (800) 874-4968 ©2009 United States Gypsum Company Printed in U.S.A. Manufactured by USG Corporation 550 West Adams Chicago, IL 60661