Homework MB #1

advertisement

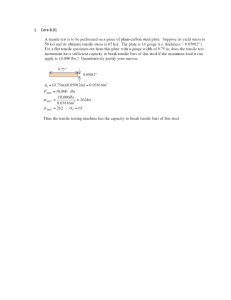

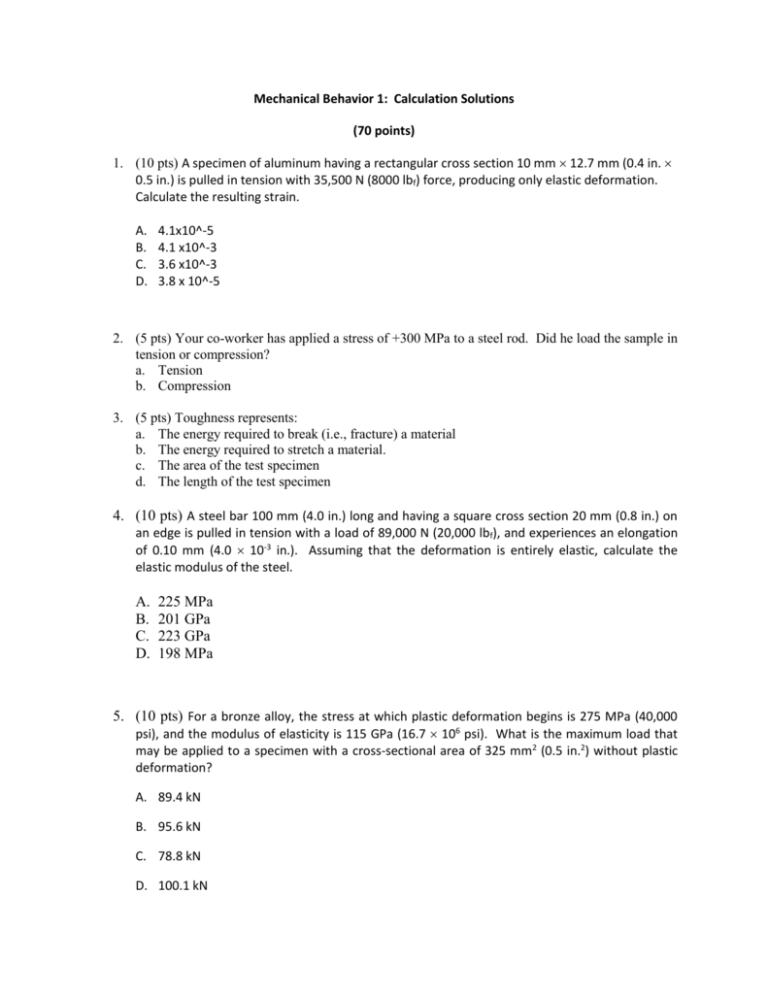

Mechanical Behavior 1: Calculation Solutions (70 points) 1. (10 pts) A specimen of aluminum having a rectangular cross section 10 mm 12.7 mm (0.4 in. 0.5 in.) is pulled in tension with 35,500 N (8000 lbf) force, producing only elastic deformation. Calculate the resulting strain. A. B. C. D. 4.1x10^-5 4.1 x10^-3 3.6 x10^-3 3.8 x 10^-5 2. (5 pts) Your co-worker has applied a stress of +300 MPa to a steel rod. Did he load the sample in tension or compression? a. Tension b. Compression 3. (5 pts) Toughness represents: a. The energy required to break (i.e., fracture) a material b. The energy required to stretch a material. c. The area of the test specimen d. The length of the test specimen 4. (10 pts) A steel bar 100 mm (4.0 in.) long and having a square cross section 20 mm (0.8 in.) on an edge is pulled in tension with a load of 89,000 N (20,000 lbf), and experiences an elongation of 0.10 mm (4.0 10-3 in.). Assuming that the deformation is entirely elastic, calculate the elastic modulus of the steel. A. B. C. D. 225 MPa 201 GPa 223 GPa 198 MPa 5. (10 pts) For a bronze alloy, the stress at which plastic deformation begins is 275 MPa (40,000 psi), and the modulus of elasticity is 115 GPa (16.7 106 psi). What is the maximum load that may be applied to a specimen with a cross-sectional area of 325 mm2 (0.5 in.2) without plastic deformation? A. 89.4 kN B. 95.6 kN C. 78.8 kN D. 100.1 kN 6. (10 pts) For a bronze alloy that is 115 mm in length, what is the maximum length the bronze alloy can be pulled to before plastic deformation initiates? Note that the stress at which plastic deformation begins is 275 MPa (40,000 psi) and the modulus of elasticity is 115 GPa (16.7 106 psi).? A. B. C. D. 115.28 mm 116.11 mm 115.05 mm 116.08 mm 7. (20 pts) A specimen of ductile cast iron having a rectangular cross section of dimensions 4.8 mm 15.9 mm (3/16 in. 5/8 in.) and is deformed in tension. Using the load-elongation data shown in the following table, complete parts (a) through (d). You will need to plot this data as engineering stress versus engineering strain to complete this problem. Load Length N lbf mm in. 0 0 75.000 2.953 4,740 1,065 75.025 2.954 9,140 2,055 75.050 2.955 12,920 2,900 75.075 2.956 16,540 3,720 75.113 2.957 18,300 4,110 75.150 2.959 20,170 4,530 75.225 2.962 22,900 5,145 75.375 2.968 25,070 5,635 75.525 2.973 26,800 6,025 75.750 2.982 28,640 6,440 76.500 3.012 30,240 6,800 78.000 3.071 31,100 7,000 79.500 3.130 31,280 7,030 81.000 3.189 30,820 6,930 82.500 3.248 29,180 6,560 84.000 3.307 27,190 6,110 85.500 3.366 24,140 5,430 87.000 3.425 18,970 4,265 88.725 3.493 Fracture (a) Compute the modulus of elasticity (5 pts). A. 207 GPa B. 197 GPa C. 200 GPa D. 212 GPa (b) Determine the yield strength at a strain offset of 0.002. (5 pts) A. 167 MPa B. 280 MPa C. 325 MPa D. 235 MPa (c) Determine the tensile strength of this alloy. (5 pts) A. 410 MPa B. 359 MPa C. 485 MPa D. 520 MPa (d) What is the ductility, in percent elongation? (5 pts) A. 24.2% B. 18.4% C. 14.6 % D. 12.8 %