EGEE 102H

advertisement

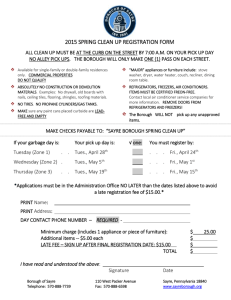

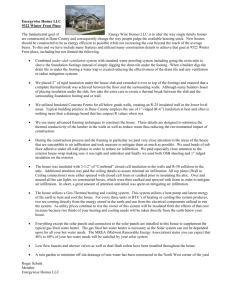

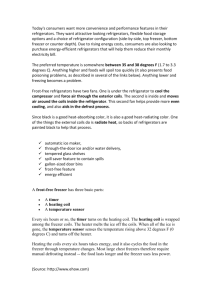

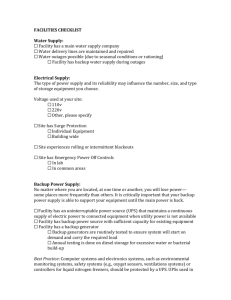

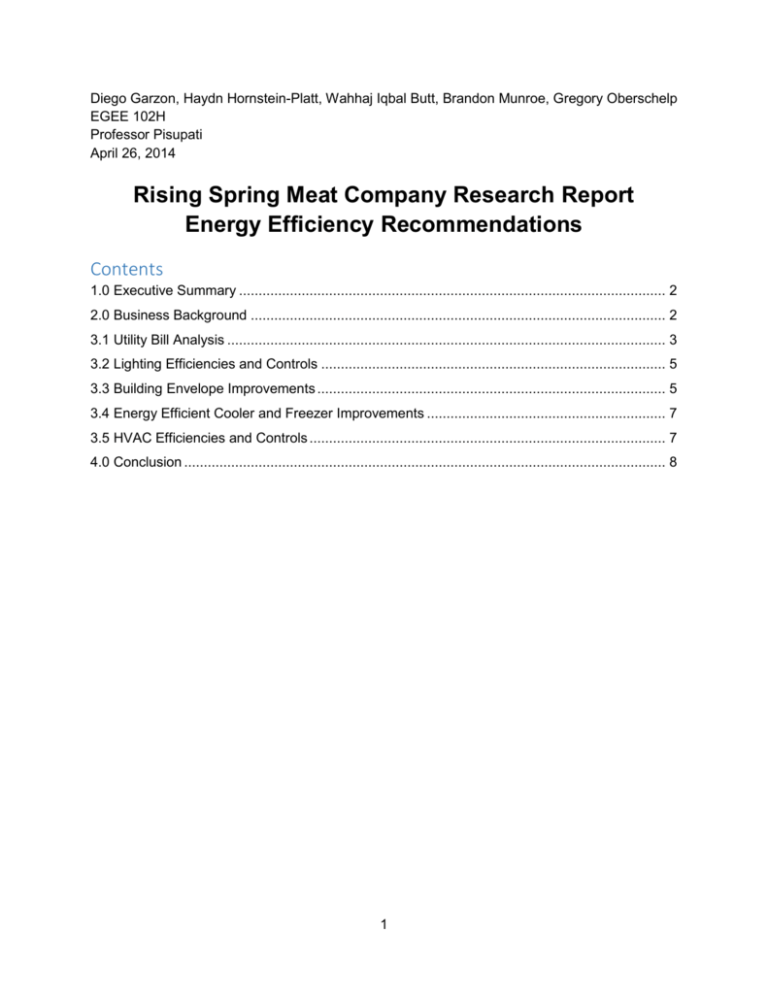

Diego Garzon, Haydn Hornstein-Platt, Wahhaj Iqbal Butt, Brandon Munroe, Gregory Oberschelp EGEE 102H Professor Pisupati April 26, 2014 Rising Spring Meat Company Research Report Energy Efficiency Recommendations Contents 1.0 Executive Summary ............................................................................................................. 2 2.0 Business Background .......................................................................................................... 2 3.1 Utility Bill Analysis ................................................................................................................ 3 3.2 Lighting Efficiencies and Controls ........................................................................................ 5 3.3 Building Envelope Improvements ......................................................................................... 5 3.4 Energy Efficient Cooler and Freezer Improvements ............................................................. 7 3.5 HVAC Efficiencies and Controls ........................................................................................... 7 4.0 Conclusion ........................................................................................................................... 8 1 1.0 Executive Summary During the on-site assessment, the following information was provided: Utility Bill Analysis for January 2012 to January 2014 Energy Usage comparison of Rising Spring with similar businesses in Pennsylvania Information on State and Federal Grant Funding, Fact Sheet Provided by EMAP. The following is a prioritized list of recommendations based on the research: Insulate remaining pipes (return lines). Replace older single-paned windows with double-paned Energy Star® rated windows – save up to $372 annually. Purchase an Energy Star® freezers and refrigerators - energy savings of as much as 35 percent with a 1.3 year payback period. Add plastic curtains on cooler doors. Seal the door. Take out room air conditioners during the winter. 2.0 Business Background Rising Spring Meat Company has a 4500 square foot facility located in Spring Mills, PA. There is a slaughterhouse where they butcher pigs, sheep, buffalo, venison, and cows, and a retail store. Both the retail store and the slaughterhouse range from 75-35 years old, due to some more recent renovations. The majority of the square footage in the meat processing portion of the facility is devoted to refrigeration, and in the retail area is devoted to a cutting room and large coolers. Rising Spring Meat Company maintains 5 employees who work one shift up to six days a week with occasional overtime. The business is open for 7-9 hours a day, 4-6 days a week. There were 50 T-8 fluorescent bulbs in the slaughterhouse and 15 T-12 bulbs in the retail area. There were no occupancy sensors to shut the lights off automatically located in the 3 large refrigerating units or the 2 coolers. The large majority of equipment for refrigeration (compressors for the coolers and freezers) are inefficient and out of date. The coolers and refrigerating units do not have any insulation, and have cinderblock walls separating the units from outside, and there are no plastic curtains on any cooler doors. The ceiling has 6’’ cellulose insulation. The facility is currently using a 2-year old, 238 MMBTU HVAC system that operates on oil. 2 3.1 Utility Bill Analysis Note: The Business did not provide us with the data of gas or oil energy bills YEAR:2012-2014 Month # Days in billing period June 28 July 32 Aug 30 Sept 29 Oct 31 Nov 29 Dec 28 Jan 33 Feb 28 Mar 29 April 33 May 30 June 29 July 32 Aug 30 Sept 29 Oct 31 Nov 29 Dec 31 Jan 34 605 Electric Electric Usage Demand kWh kW 2,190 26 7,867 26.5 8,024 26 7,366 26 8,220 26 6,936 26 7,262 36 4,896 19.5 4,282 20.5 4,606 24.5 6,732 26.5 8,987 30 2,190 26 7,867 26.5 8,024 26 7,366 26 8,220 26 6,936 26.5 5,532 20 5,044 19.5 128547 25.5 $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ Electric Cost $ 185.84 582.61 592.99 530.07 587.01 501.06 567.48 390.90 346.92 369.38 526.77 695.88 185.84 582.61 592.99 530.07 587.01 501.06 567.48 883.17 $10,307.14 ELECTRIC Electric Electric Electric Load Factor Service Total cost Unit Cost MMBtu Charge $ $/kWh $ 185.84 $0.085 7.47 0.13 $ 582.61 $0.074 26.84 0.39 $ 592.99 $0.074 27.38 0.43 $ 530.07 $0.072 25.13 0.41 $ 587.01 $0.071 28.05 0.42 $ 501.06 $0.072 23.67 0.38 $ 567.48 $0.078 24.78 0.30 $ 390.90 $0.080 16.71 0.32 $ 346.92 $0.081 14.61 0.31 $ 369.38 $0.080 15.72 0.27 $ 526.77 $0.078 22.97 0.32 $ 695.88 $0.077 30.66 0.42 $ 185.84 $0.085 7.47 0.12 $ 582.61 $0.074 26.84 0.39 $ 592.99 $0.074 27.38 0.43 $ 530.07 $0.072 25.13 0.41 $ 587.01 $0.071 28.05 0.42 $ 501.06 $0.072 23.67 0.38 $ 567.48 $0.103 18.88 0.37 $ 883.17 $0.175 17.21 0.32 $ $ 10,307.14 $0.082 438.60 0.35 3 Load factor is not written on your electricity bill, but it still affects electricity costs. Essentially, it analyzes how well your business currently utilizes peak demand. Throughout the day, energy is used at different rates, and during peak times, the electricity costs are higher. The higher cost helps the electricity provider account for the increased demand during these times. The load factor for Rising Spring Meat is lower than average and inconsistent, which makes costs unnecessarily high. Increasing your load factor is possible by reducing demand and increasing production. By distributing your energy use over time, the amount used at peak times will be diminished, thus reducing demand and saving money. Another option is to increase production, by keeping operations moving the demand is kept constant. This will fix your current inconsistency with energy usage. 4 3.2 Lighting Efficiencies and Controls There are 25 T8 lights in total. Each light has a dimension of 4 ft. and consumes 32 watts. The lights are on during the hours of operation which are from Monday through Friday (7 am to 9 pm). The light in the freezers and refrigerators is always on. The desired amount of time that lights should be off is 10 hours per weekday while store is closed and another 48 hours during weekends. We would recommend to install occupancy sensors but as the T8 lights are already efficient the payback period to recover the investment is around 7 - 10 years. 3.3 Building Envelope Improvements Window Upgrades -Upgrading the windows would decrease the amount of electricity required to run Rising Spring. Several of the windows in the facility have cracks, thus allowing heat to escape. We highly recommend replacing these cracked windows, and the single paned windows to Energy Star® double paned windows. Installing Energy Star® qualified windows, doors, and skylights lowers energy bills and saves you money. With more efficient windows, you also use 5 less energy, which reduces greenhouse gas emissions from power plants. If we upgrade to Energy Star®, the annual savings predicted by the Energy Star® website is $372 for East North Central area. Weather Stripping -We recommend door seals on the front door of the establishment. During our examination of the premises, it was clear that there were significant cracks between the door and the door frame that allowed for cold air to come in and for hot air to leave the store. We also highly encourage Rising Spring to remove room air conditioning units from the windows during the winter. There were clearly large gaps through which air could flow surrounding the air conditioning units. Storing these somewhere during the winter would conserve a significant amount of money. Insulation The larger cooler and freezer are definitely in need of additional insulation. The ceiling, which is above both the cooler and freezer, is insulated with 6’’ cellulose, but the outside walls consist of only cinderblock. The cooler is approximately 300 square feet, and the freezer is approximately 400 square feet. It is advisable that additional insulation should be added to the ceiling, and insulation should be added to the surrounding walls. Below is a chart of R-value (insulation efficiency). The current combined R-value of the attic is around 22 - 40.It is suggested that the State College area have a combined R-value of 49-60 in the attic. 25-30 in the floor, and 5-6 in the walls. We also suggest adding plastic curtains to all cooler and refrigerator doors to prevent excess heat loss while using the equipment. The return lines for the boiler are not properly insulated. Adding some cheap insulation to these pipes could increase some savings as well. 6 3.4 Energy Efficient Cooler and Freezer Improvements Having efficient coolers and freezers is incredibly important, especially since this is such a large percentage of the energy consumption at Rising Springs. The freezers are homemade and really old, our recommendation would be to install Energy Star® labeled commercial refrigerators and freezers. These are more energy efficient because they are designed with components such as ECM evaporator and condenser fan motors, hot gas anti-sweat heaters, or high-efficiency compressors, which will significantly reduce energy consumption and utility bills Compared to standard models, Energy Star® labeled commercial refrigerators and freezers can lead to energy savings of as much as 35 percent with a 1.3 year payback period. The following is a list of practices that are easy to implement and will result in a reduction in energy consumption from the same cooling units: ● Keep refrigerators and coolers closed as much as possible ● Keep condenser coils clean and give them proper space (several inches at least of empty space behind the refrigeration unit) to release heat ● Do not put cooling units in the vicinity of anything hot (Ex: oven, window, etc.) ● Ensure that seals on doors do not allow air out or in ● Maintain constant temperatures (refrigerator between 35°F and 38°F, freezer at 0°F) ● Keep cooling units as full as possible so that there is less space for warm air to occupy when the door is opened ● Let anything hot cool down before placing it into refrigeration or freezing unit ● Defrost freezers regularly 3.5 HVAC Efficiencies and Controls Boiler Upgrade The current boiler at Rising Springs is an oil fired boiler for heating and hot water. It is less than 2 years old, and 238 MMBTU. The return and feed lines are insulated in the boiler room, but once the pipes extend beyond that room they are not insulated. These lines total approximately 35 feet long. In general, Energy Star® products are significantly more efficient, utilizing about 85% of energy, which is about 20% better than regular boilers. There is no need to change the boiler as the current one has been used just for two years. Purchasing a thermostat can regulate the temperature of the water, and have it hot when you need it, instead of all of the time. The business had installed thermostats which is great investment on their part. 7 4.0 Conclusion In conclusion the business has a lot of ways to cut down the energy bills. The lighting is very efficient. But the freezers and the refrigerators are really old and have leaks. The building is not very well insulated. They require to increase the insulation in the freezers refrigerators, attic, walls, in order to cut down the energy bills. The air conditioners are always on the windows, they can remove them in the winter to avoid the heat inside to escape. All in all if the recommendations are implemented. The energy bills can shrink by 30-40%. This is a huge number and would increase the efficiency of the business, therefore leaving them with more money to spend on other areas. 8