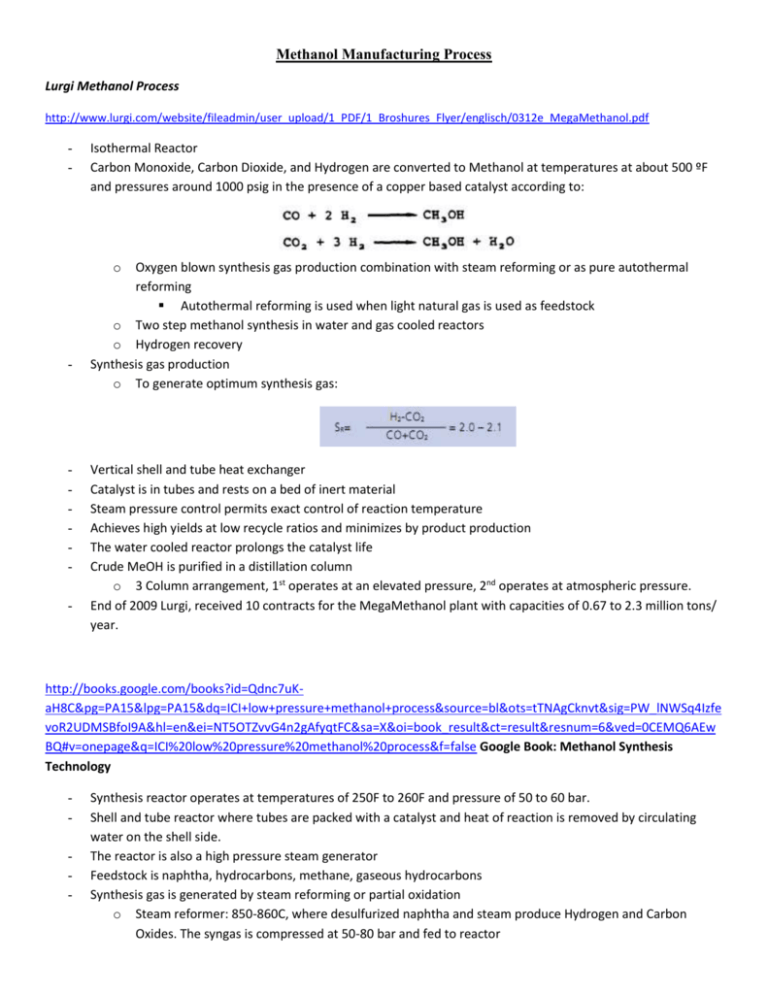

Methanol Manufacturing Process

advertisement

Methanol Manufacturing Process Lurgi Methanol Process http://www.lurgi.com/website/fileadmin/user_upload/1_PDF/1_Broshures_Flyer/englisch/0312e_MegaMethanol.pdf - Isothermal Reactor Carbon Monoxide, Carbon Dioxide, and Hydrogen are converted to Methanol at temperatures at about 500 ºF and pressures around 1000 psig in the presence of a copper based catalyst according to: o - - Oxygen blown synthesis gas production combination with steam reforming or as pure autothermal reforming Autothermal reforming is used when light natural gas is used as feedstock o Two step methanol synthesis in water and gas cooled reactors o Hydrogen recovery Synthesis gas production o To generate optimum synthesis gas: Vertical shell and tube heat exchanger Catalyst is in tubes and rests on a bed of inert material Steam pressure control permits exact control of reaction temperature Achieves high yields at low recycle ratios and minimizes by product production The water cooled reactor prolongs the catalyst life Crude MeOH is purified in a distillation column o 3 Column arrangement, 1st operates at an elevated pressure, 2nd operates at atmospheric pressure. End of 2009 Lurgi, received 10 contracts for the MegaMethanol plant with capacities of 0.67 to 2.3 million tons/ year. http://books.google.com/books?id=Qdnc7uKaH8C&pg=PA15&lpg=PA15&dq=ICI+low+pressure+methanol+process&source=bl&ots=tTNAgCknvt&sig=PW_lNWSq4Izfe voR2UDMSBfoI9A&hl=en&ei=NT5OTZvvG4n2gAfyqtFC&sa=X&oi=book_result&ct=result&resnum=6&ved=0CEMQ6AEw BQ#v=onepage&q=ICI%20low%20pressure%20methanol%20process&f=false Google Book: Methanol Synthesis Technology - Synthesis reactor operates at temperatures of 250F to 260F and pressure of 50 to 60 bar. Shell and tube reactor where tubes are packed with a catalyst and heat of reaction is removed by circulating water on the shell side. The reactor is also a high pressure steam generator Feedstock is naphtha, hydrocarbons, methane, gaseous hydrocarbons Synthesis gas is generated by steam reforming or partial oxidation o Steam reformer: 850-860C, where desulfurized naphtha and steam produce Hydrogen and Carbon Oxides. The syngas is compressed at 50-80 bar and fed to reactor Atlas Methanol Production Plant, Point Lisa, Trinidad and Tobago http://www.chemicals-technology.com/projects/atlas_methanol/ - Project cost $400million MegaMethanol from Lurgi, Built next to an existing plant Methanol production process: oxygen synthesis gas reforming, 2 step Lugi methanol synthesis and hydrogen recycle Allows for the production of 5000 ton/day. Stainless steel pipes, electrical installation ICI ( Imperial Chemical Industries) Low Pressure Methanol Synthesis Process http://books.google.com/books?id=Qdnc7uKaH8C&pg=PA15&lpg=PA15&dq=ICI+low+pressure+methanol+process&source=bl&ots=tTNAgCknvt&sig=PW_lNWSq4Izfe voR2UDMSBfoI9A&hl=en&ei=NT5OTZvvG4n2gAfyqtFC&sa=X&oi=book_result&ct=result&resnum=6&ved=0CEMQ6AEw BQ#v=onepage&q=ICI%20low%20pressure%20methanol%20process&f=false Google Book: Methanol Synthesis Technology - - Low pressure methanol was developed by ICI in the late 1960’s A widely used catalyst is a mixture of Copper, Zinc Oxide, and Alumina used by ICI in 1966 1st ICI unit produced 300 tons of refined methanol per day o Had a syngas feed containing H2, CO, CO2, CH4 o Shaft converter adjusted the CO to CO2 ratio o Feed compressed to 50 atm in centrifugal compressor and fed to quench type converter at 270°F o Product was cooled and methanol was condensed out o Purge gas stream was recycled to a reformer to convert accumulated methanol into synthesis gas o Low pressure operation meant lower methanol concentration therefore higher recycle rates o The crude methanol that was produced by the low pressure process contained water, dimethyl ether, esters, ketones, iron carbonyls, and higher alcohols. Linde Isothermal Reactor http://www.lindeengineering.com/en/process_plants/hydrogen_and_synthesis_gas_plants/gas_products/methanol/index.html# Fixed bed reactor cooled by coiled pipes and catalyst is cooled and maintained at Optimum Temp. by steam production Uses the ICI methanol technology Process for the synthesis of a Methanol and DME Mixture from Synthesis Gas http://www.freepatentsonline.com/6191175.pdf