Press Release

advertisement

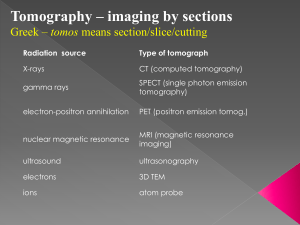

PRESS RELEASE Corneliusstrasse 4 60325 Frankfurt am Main GERMANY Tel. +49 69 756081-0 Telefax +49 69 756081-11 Email presse@vdw.de From Tel. Telefax Email www.metav.de Sylke Becker +49 69 756081-33 +49 69 756081-11 s.becker@vdw.de Speeding up quality assurance in ICT tempo Scanner-based quality checks: industrial computer tomography Frankfurt am Main, 17 December 2015. – Lightweight construction also affects quality assurance: customers are demanding multi-material components, e.g. made of aluminium and steel, whose interior – as the Quality Area at the METAV 2016 in Düsseldorf from 23 to 27 February will show – can be particularly effectively scanned and checked using industrial computer tomography. New development themed around metrology are of particular interest to Andrea Buratti, a research assistant in the Model-Based Systems Department at the Machine Tool Laboratory (WZL) of RWTH Aachen University, not only because of his daily hands-on involvement with state-of-the-art metrology. Which is why he thinks a Quality Area at the METAV 2016 is definitely a good idea. There, he can take a long hard look at state-of-the-art metrological equipment in close interaction with production technology. He’s very interested in industrial computer tomography (ICT). Page 2 / 5 METAV 2016 What are the attractions of this technology, which has proved its worth in the field of medical technology, in particular? It provides a complete three-dimensional reconstruction of the object being tested, with which the tester can analyse minuscule internal structures and defects, without destroying the object concerned. For the scan, the object concerned is placed in the computer tomography unit between the Xray source and the detector, and the test piece is gradually turned by 360 degrees. After every step, a two-dimensional radiographic image, known as a projection, is created on the detector. From the individual two-dimensional images, the electronics finally create a volume model, from which the computer calculates surface data. The Machine Tool Laboratory in Aachen can draw upon long years of experience with ICT, since it’s been working and researching on one of the first prototypes since 2007. The primary focus of ongoing research is on operator control. To quote Andrea Buratti: “Nowadays, we’re primarily working on simplifying the handling involved in the scanning operation.” Hitherto, before scanning a component, operators have had to laboriously re-enter the characteristic values of the ICT device each time, in order to obtain optimum measurements and to minimise measuring uncertainties. Automatic scanning of multi-material components The goal of the development work in conjunction with the industrial sector is to automate the manually elaborate calibration process. The research work is based on a knowledge-based system developed at the Machine Tool Laboratory, which has already proved its worth with automatic calibration of components made from one material. “In our ongoing research work, in the EU’s “Interact” research project, for example, we’re dealing with multi-material components,” explains the Machine Tool Laboratory’s scientist. “We’re currently attempting to find a solution together with the industrial sector.” Page 3 / 5 METAV 2016 ICT has already proved its worth in production operations for doorlocking systems in automobiles, i.e. classical multi-material components. To quote Andrea Buratti: “The interior of these systems, with their complex geometry, can basically be acquired in detail only by means of scanning. Computer tomography is the right solution for this.” With an automated calibration process, automotive component suppliers would no longer have to laboriously make manual changes to the ICT parameters with every new variant. Our design enhancements make working with computer tomography faster and more reliable,” is Andrea Buratti’s verdict. Quality Area: a specialised fair within the METAV This kind of research is entirely in the interests of CT manufacturers like Wenzel Group GmbH & Co. KG from Wiesthal, who are exhibiting at the METAV for a variety of reasons. “I really like the METAV’s fresh and more focused concept”, explains Managing Director Frank Wenzel. “We’ve also had discussions ourselves whether it’s worthwhile participating in the METAV. But now that the fair has been refocused, the matter is settled as far as we’re concerned.” His company represents the category of metrology, which after all in future will be integrated with the Quality Area in its own zone at the METAV. Wenzel thinks it’s a good idea to create thematically harmonised areas at a large trade fair featuring numerous different technologies. As he says: “This makes it easier for visitors to find their way around.so you have a sort of specialised fair embedded in the event. This concept has proved its worth at other international trade like the Hanover Fair.” In Düsseldorf, Wenzel will be showcasing new solutions from coordinate and toothing metrology, plus industrial computer tomography. Author: Nikolaus Fecht, specialist journalist from Gelsenkirchen Number of characters including blanks: 4,787 Page 4 / 5 METAV 2016 Background Faculty for Production Metrology and Quality Management, RWTH Aachen University The Faculty for Production Metrology and Quality Management at the Machine Tool Laboratory of RWTH Aachen University performs research and teaching in the following core specialisms: development and optimisation of measuring processes and instruments, production-integrated metrology and close-to-machine quality control circuits, quality management systems, knowledge, innovation and improvement management, plus methods and computer support for quality management. Further information under: www.wzl.rwth-aachen.de/de/mq_lehre.htm Wenzel Group GmbH & Co. KG, Wiesthal The Wenzel Group offers a comprehensive product portfolio in the categories of coordinate metrology, toothing metrology, computer tomography, optical high-speed scanning and styling solutions. Technology from Wenzel is used in all branches of industry, including the automotive sector, aviation, energy extraction and medical. Nowadays, the company can point to an installed base of more than 10,000 machines worldwide. Subsidiaries and agencies in more than 50 different countries support our sales operation, and assure responsive after-sales service for our customers. Employees: 650 Further information under: www. wenzel-group.com METAV 2016 in Düsseldorf The METAV 2016 – the 19th International Exhibition for Metalworking Technologies – will be held in Düsseldorf from 23 to 27 February. It showcases the entire spectrum of production technology. The principal focuses are machine tools, production systems, high-precision tools, automated material flows, computer technology, industrial electronics, and accessories, complemented by the new themes of Moulding, Medical, Additive Manufacturing and Quality, which are now permanently anchored in what are called “areas” with their own nomenclature in the METAV’s exhibition programme. The METAV’s target group for visitors includes all branches of industry that work metal, particularly machinery and plant manufacturers, the automotive industry and its component suppliers, aerospace, the electrical engineering industry, energy and medical technologies, tool and mould-making, plus metalworking and the craft sector. Quality Area auf der METAV 2016 Methods for quality assurance are developing at a rapid pace, belong in every manufacturing process, and are therefore of interest to all production experts. One of the crucial elements for quality is modern-day metrology. Users are demanding progressively shorter measuring times, which is why more and more functions are being integrated into the individual machines. In addition, consistent processing of the measured results during the course of machine monitoring and process control is gaining steadily in perceived importance. Industry 4.0 is now being complemented by Quality 4.0. The Quality Area is ideally intermeshed in the keynote topics addressed by the METAV, and the declared aim of ensuring high standards of quality throughout all phases of the production process. It showcases the entire bandwidth of measuring and testing technology, plus QM and analytical systems. Further information under: www.metav.de Page 2 / 5 METAV 2016 Your contact persons VDW (German Machine Tool Builders’ Association) Sylke Becker Press and Public Relations Corneliusstrasse 4 60325 Frankfurt am Main GERMANY Tel. +49 69 756081-33 s.becker@vdw.de www.vdw.de Wenzel Group GmbH & Co. KG Steffen Hochrein Marketing Werner-Wenzel-Strasse 97859 Wiesthal GERMANY Tel. +49 6020 201-6114 steffen.hochrein@wenzel-cmm.com www.wenzel-group.com Machine Tool Laboratory (WZL) of RWTH Aachen Reinhard Freudenberg Press and Public Relations Steinbachstr. 19 52074 Aachen GERMANY Tel. +49 241 80-27614 r.freudenberg@wzl.rwth-aachen.de www.wzl.rwth-aachen.de Press Agency Dipl.-Ing. Nikolaus Fecht Technical texts à la carte – when words fail you Nikolaus Fecht Husemannstrasse 29 45879 Gelsenkirchen GERMANY Tel. +49 209 26575 nikofecht@erzfreunde.de You will find texts and pictures on the internet under www.metav.de in Press Service. You can also visit the METAV through our social media channels http://twitter.com/METAVonline http://facebook.com/METAV.fanpage http://www.youtube.com/metaltradefair https://de.industryarena.com/metav