Project Name - Wilson Memorial General Hospital

advertisement

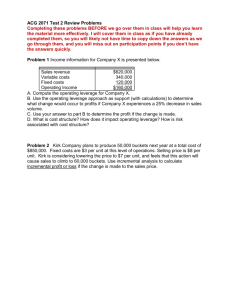

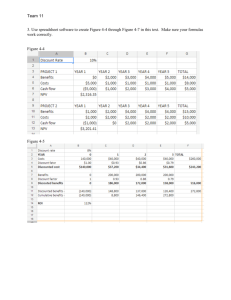

Wilson Memorial General Hospital Energy Conservation and Demand Management Plan (2014) Wilson Memorial General Hospital (WMGH) has prepared this plan to ensure compliance with our obligations under the Green Energy Act 2009, which requires public agencies, including hospitals to report on their energy consumption and greenhouse gas emissions and to develop energy conservation and demand management plans. In alignment with regulations, WMGH reported calendar year 2011 energy consumption and greenhouse gas emissions on the Province of Ontario Reporting Portal, in 2013. During 2014, we will report the same information for calendar years 2012 and 2013 and will publish this Energy Conservation and Demand Management Plan (ECDM) on our website at www.wmgh.net Facility Description WMGH operates a two storey, 43,971 square foot hospital facility in the Town of Marathon. The facility services the Town of Marathon, Pic River First Nation and Pic Mobert First Nation, as well as visitors to the area and travellers utilizing the nearby Trans Canada Highway. The facility was originally built in 1969 and was comprehensively renovated in 2002-2005. WMGH utilizes three energy sources to meet its demands: electricity purchased through the provincial Hydro One grid, propane delivered via truck from a national supplier, and fuel oil delivered by truck from a regional supplier. WMGH does not currently consume or produce energy from local renewable sources such as solar generation, wind generation, biomass burning or ground source heat generation. Energy Consumption Energy consumption in a hospital facility is quite variable based upon a number of factors including, most notably, weather (temperature, humidity, wind speed, wind direction, cloud cover), building occupancy and energy demand and consumption projects. Of particular note, the hospital has no ability to control weather and limited ability to control occupancy; making it particularly difficult to control and forecast energy demand. WMGH utilizes electrical energy, purchased from Hydro One to run many of the basic functions in our facility ranging from lights, pumps and fans to office and medical equipment. Our consumption for the past three calendar years is as follows: 2011 889,753 kwh 2012 870,785 kwh 2013 804,577 kwh WMGH utilizes minor amount of propane purchased from a national supplier, as a cooking fuel for our dietary department, in the laundry dryers and as a heating fuel for a patient lounge fireplace. Our consumption for the past three calendar years is as follows: 2011 19,437 litres 2012 11,670 litres 2013 15,137 litres WMGH utilizes fuel oil purchased from a regional supplier as a heating fuel for our two low pressure steam boilers which provide both heat and hot water for our complete hospital facility. Fuel oil consumption is particularly variable, dependant on weather conditions. Of note, the 2013 winter in Northern Ontario arrived unusually early in 2013, was colder than normal and lasted longer than usual into 2014. We can anticipate elevated fuel oil consumption into 2014, as well, as a result. Our consumption for the past three calendar years is as follows: 2011 195,031 litres 2012 192,104 litres 2013 246,951 litres ECDM goals Due to the potential variability of energy consumption due to uncontrollable factors previously mentioned, WMGH has not set specific energy targets. Instead our goals are to 1) track consumption; 2) identify consumption trends; 3) identify energy and greenhouse gas emission reduction projects and 4) prioritize and implement projects. Energy reduction aligns with one of our strategic directions – sustainability, and, as such, has been given priority by our Board of Directors. The prioritization of projects will be based upon three criteria: payback period, funds availability and technical risk. Paybacks for all significant projects must be less than five years to ensure an efficient use of scarce financial resources. The availability of these financial resources is currently limited to MOHLTC Hospital Infrastructure Renewal Funds (HIRF), corporate incentives with energy partners such as Hydro One and any surplus operating funds. WMGH is currently operating in a deficit position and does not have capital reserves to draw upon to fund capital projects. Prior Accomplishments WMGH has taken a proactive approach to energy conservation and have actively incorporated energy conservation projects into our long term capital program for many years. Over the past ten years, we have successfully completed the following energy conservation projects: Replacement of all four central air handling units of 1970 vintage, resulting in significant increases in electrical and heating efficiencies and improved indoor air quality Decommission of the high pressure boiler and replacement with a smaller, on-demand steam generator to accommodate the MDRD department sterilization needs. Re-envelop of the entire building with new energy efficient windows and doors. Transition of interior lighting from 32 watt fluorescent to more efficient 25 watt fixtures. Installation of a sophisticated building management system which provides full control and automation of heating and ventilation and exterior lighting systems. Conversion from direct steam heating to more efficient heat exchangers. Upgrade of piping insulation and hot water storage system to improve heat retention within the system. Replacement of antiquated medical vacuum system, resulting in improved system reliability and energy efficiency. Upgrade of three local air exchange systems to improve HVAC control and efficiency. Replacement of an inefficient steam condensate system, resulting in improved recapture of waste steam and reduced heating demand. Refurbishment of aged steam traps. These initiatives were the direct result of our focus on energy efficiency. A combination of inhouse expertise, consulting engineering expertise and independent audits by VIP Energy and VFA Canada, have allowed WMGH to achieve impressive energy conservation results and provided the basis for some future improvement. As noted in the VIP Energy audit (2012), “it is evident that the Wilson Memorial General Hospital fares better on average than other hospitals.” The energy consumption index for Ontario hospitals records average consumption of approximately 2.5 GJ/m2. WMGH’s consumption of approximately 2.0 GJ/m2, compares very favourably to this Provincial average. Future Opportunities Wilson Memorial General Hospital’s 5 year plan for energy reduction opportunities is based upon the VIP Energy Services Inc. audit which was published on May 19, 2012. VIP is a privately held company with extensive experience providing detailed audits. Because VIP is not a supplier of equipment, nor affiliated with any equipment suppliers, they are able to provide independent non-biased energy management advice. VIP has identified 8 projects with potential for near term implementation at WMGH: Project Name: Install Variable Frequency Drives (VFD) on Air Handling Units Description: supplement existing CO2 sensors and building management system scheduling, with VFDs, to actively control air flow rates. Cost Savings Payback $56,000 $29,477 1.9 yrs Strategy: concern remains with complexity of operating system and the ability of our maintenance staff to effectively maintain VFD controls. Existing AHUs are less than 10 years old. Consideration will be given to replacing standard motors and controls with a VFD system, when replacement of existing motors is required or if specific funding can be sourced to implement this project. Project Name: Upgrade motors to super premium efficiency motors Description: upgrade of existing standard efficiency motors. Cost Savings Payback $11,649 $975 11.9 yrs Strategy: VIP recommends that this opportunity is implemented over time during the normal replacement of motors due to failure. Project Name: HVAC balance Description: Study and re-distribution of airflows to ensure systems are not “fighting against each other”. Cost Savings Payback $18,000 $6,507 2.8 yrs Strategy: Consideration to this project will be given during the 15/16 budget cycle and is dependent on available project funding. Project Name: Steam Trap Check & Repair Description: Complete audit of all facility steam trap and repair, as required. Cost Savings Payback $5,000 $2,619 1.9 yrs Strategy: Two traps have been replaced in 12/13. Additional inspection and repair to occur as part of preventive maintenance routine. Project Name: Lighting retrofits Description: Replacement of existing 32w fluorescent bulbs with 25w fluorescent bulbs. Cost Savings Payback $31,539 $4,381 7.2 yrs Strategy: WMGH has adopted the practice of replacing all 32w bulbs with 25w bulbs, as the bulbs “burn out”. This results in no incremental implementation costs and immediate efficiency payback. Project Name: Insulation Upgrades Description: installation of insulation on all unions, valves and steam traps to reduce heat loss. Cost Savings Payback $55,000 $10,802 4.9 yrs Strategy: the majority of this project was completed during our 2012/13 HIRF project upgrades. Remaining insulation on minor piping sections will be completed by our maintenance personnel during the 14/15 operating year. Project Name: Energy and Resource Awareness Description: Development of energy awareness programs to promote a fundamental shift in employees’ philosophies towards reducing energy usage. Cost Savings Payback $12,000 $6,375 1.9 yrs Strategy: WMGH will promote the development of such a program at a NWLHIN wide level, to ensure consistency of message, maximization of results and sharing of scarce human resources who can develop and deliver this education. Project Name: Installation of Cogged Belts Description: Replacement of standard flat v-belts for drive motors reduces fan power consumption by 2%. Cost Savings Payback $800 $453 1.8 yrs Strategy: WMGH has adopted the practice of replacing all standard v-belts with cogged belts, if available, upon failure or deemed end of life of the v-belt. Full copies of the VIP Energy Audit are available to the public by contacting the administration office at WMGH. In addition to the realized successes and plans for future improvement, WMGH has also reviewed opportunities for the installation of renewable energy generation, notably solar, under the Ontario Power Authority Micro-Fit program. Our investigations with third party suppliers indicated relatively high up front implementation costs of approximately $350,000, with relatively poor payback periods of 7.2 years. Additionally, our investigations uncovered several areas of risk which were not quantified in this payback period, including: increased maintenance costs for snow and debris removal around the installation and chance of roof damage to our Sono-fil roofing system. We were not comfortable with significantly debt levering our corporation, in light of these risks, to pursue solar installations at this time. As solar energy generation technology continues to advance, WMGH will remain aware of any opportunities for improved project economics and adjust our plan, as necessary. Conclusion Wilson Memorial General Hospital has been and will remain proactive and committed to controlling and reducing our energy consumption and greenhouse gas emissions. Our Energy Consumption and Demand Management Plan recognizes the significant strides already made in our facility and balances future opportunities for improvement with limitations of economic and technical realities. This plan has been reviewed and endorsed by WMGH’s Board of Directors and Administration.