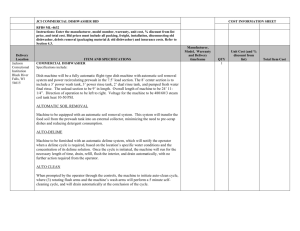

MSDF Cost Sheet

advertisement

Cost Sheet for MSDF Commercial Flight-Style Dishwasher – RFB# JL-5178A Install Location: Milwaukee Secure Detention Facility 1015 North 10th Street Milwaukee, WI 53205-0740 Instructions: Enter the manufacturer, model number, warranty, unit cost, percent discount from list price, and total cost. Bid prices must include all packaging, freight, installation, disconnecting old dishwasher, debris removal, (packaging material and old dishwasher) and insurance cost. Refer to Section 4.3. The cost should reflect installation of the machine after hours (3rd shift) at the facility. Unit Cost: % Discount from List: ____________ ____________ Manufacturer: ____________ Model: _________ Total Cost: ____________ Delivery Timeframe: ____________ Warranty: ___________ Trade In Allowance of Existing Machine: ____________ Specs of machine being bid should be equivalent to: Dish machine will be a fully automatic flight-type dish machine with automatic soil removal system and power recirculating prewash in the 8.5’ load section. The 5’ center section is to include a 3’ power wash tank, 2’ dual rinse tank, and pumped fresh water final rinse. The unload section to be 9’ in length. Overall length of machine to be 23’ 10-3/4” Direction of operation to be Left to right. Chamber opening to be 28 “ high x 29-13/16” wide. Voltage for the machine to be 480/60/3 steam coil tank heat 10-50 PSI with Low Pressure Steam option. Circuit breakers to be ordered with unit. AUTOMATIC SOIL REMOVAL SYSTEM (ASR): Two foot section with specialized soil removal wash arms which removes food soil from the ware before it reaches the prewash tank. System will pump food soil from the ASR tank into an external collector located under the load section. AUTO-DELIME Machine to be furnished with an automatic delime system, which will notify the operator when a delime cycle is required, based on the location’s specific water conditions and the concentration of its delime solution. Once the cycle is initiated, the machine will run for the necessary length of time, drain, refill, flush the interior, and drain automatically, with no further action required from the operator. AUTO CLEAN When prompted by the operator through the controls, the machine to initiate auto-clean cycle, where (3) rotating flush arms and the machine’s wash arms will perform a 5 minute self-cleaning cycle, and will drain automatically at the conclusion of the cycle. ENERGY RECOVERY Energy recovery system to be included with the dish machine. System will preheat an incoming cold water line with the exhaust from the dish machine, and feed the heated water to the machine’s booster heater. VENTLESS TECHNOLOGY Machine to be equipped with an Energy Recovery system that will capture the heat from the waste air, and use the recycled energy to heat the machine’s final rinse water and blower dryer. CONSTRUCTION Tanks to be deep drawn, without any welds, and constructed of #16 gauge stainless steel. Chamber prewash, power wash, and power rinse inspection doors to be fully insulated and hinged with No.3 polish on appearance surfaces. Sliding wash arms will not include caps that need to be removed or that can be lost. Stainless steel back panels and lower front panels to provide an air gap for a cooler surface area and a reduction in heat loss. Conveyor drive gear to be constructed of cast stainless steel. Easily removable curtains to be placed between each section to aid in heat retention. PUMPS Prewash and dual rinse pumps to produce a flow rate of 150 gallons per minute, and power wash and power rinse pumps to produce a flow rate of 292 gallons per minute. All pumps and impellers to be stainless steel and self-draining. Easy to reach pump clean-outs to be provided for each pump. MOTORS All pump motors to be totally enclosed fan cooled motors. Prewash pump to be 3 ½ HP, and the wash and power rinse pump motors to be 5 HP. Each motor to have inherent overload protection. CONTROLS Machine to include microprocessor controls equipped with service diagnostics, dirty water indicators, delime notifications, machine status updates, and digital temperature readouts. Controls to allow the operator to initiate auto-clean and auto-delime. Controls to be trilingual: English, Spanish, and French. Conveyor start/stop switches ergonomically located at the load and unload section CONVEYOR DRIVE UNIT: Powered by a 1⁄3 H.P. motor. Trip mechanism provided on unload section. Jam protection is provided by load sensing switch at drive platform. Conveyor speed adjustment of 4 feet per minute to 6.3 feet per minute is provided on the digital display keypad. DRAINS Machine to be equipped with both manual and automatic drains. The electronic drain to allow for automatic draining following an auto-clean or auto-delime cycle. Manual drains to be opened and closed by means of a heavy gauge handle connected to a brass body and stainless steel ball valve. Drain to load end. CLEAN OUT ACCESS Extension panels on load and unload sections to be completely removable without the use of tools for easy cleaning. STRAINER SCREENS Prewash, power wash and power rinse scrap screens to be one piece slanted design slopped toward the front of the machine and the large removable 16 gauge stainless steel scrap basket. Scrap system to be inside chamber allowing for a flat front. FINAL RINSE Fresh water pumped final rinse water usage to be no more than 58 gallons per hour at a conveyor speed of 8.5 feet per minute. Rinse arms are to be snapped in place, so they are removable without tools for easy cleaning. Rinse activation to be sequenced through the use of photo electronic sensors mounted at the entrance end of the load chamber. Final rinse booster heater to be #150 steam booster 10-50 PSI with Low Pressure Steam option electrically integrated into the dish machine. BLOWER DRYER Includes (2) 2 H.P. fan motors with sealed ball bearings and overload protection. Steam heat 10-50 PSI with low pressure steam option. Airflow to come from top and sides of blower dryer. CORRECTIONAL PACKAGE Standard Security Package that includes: security screws, lockable cover over controls, lockable doors and lockable control panel.