Gas Act - Annual Report 2015

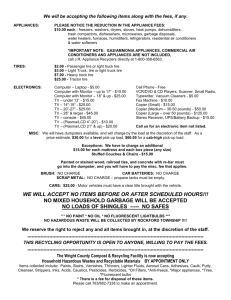

advertisement