casc autonomy asabe 2010 outline

advertisement

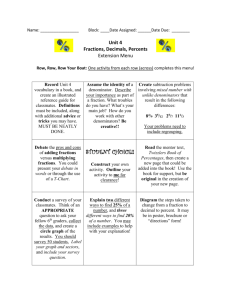

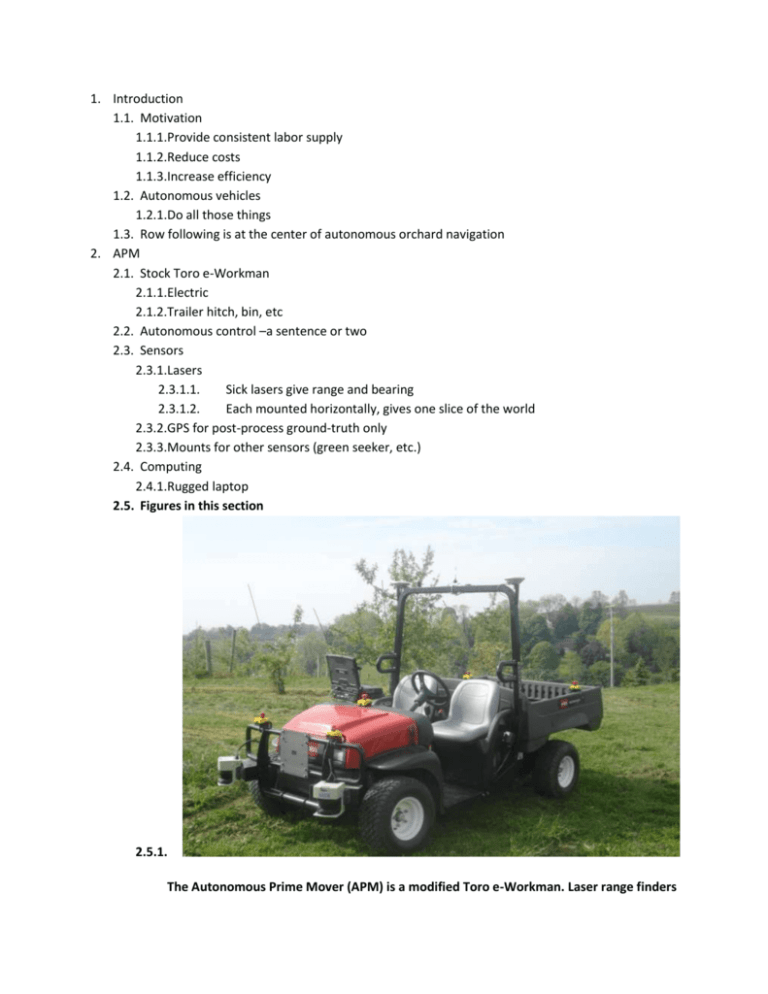

1. Introduction 1.1. Motivation 1.1.1.Provide consistent labor supply 1.1.2.Reduce costs 1.1.3.Increase efficiency 1.2. Autonomous vehicles 1.2.1.Do all those things 1.3. Row following is at the center of autonomous orchard navigation 2. APM 2.1. Stock Toro e-Workman 2.1.1.Electric 2.1.2.Trailer hitch, bin, etc 2.2. Autonomous control –a sentence or two 2.3. Sensors 2.3.1.Lasers 2.3.1.1. Sick lasers give range and bearing 2.3.1.2. Each mounted horizontally, gives one slice of the world 2.3.2.GPS for post-process ground-truth only 2.3.3.Mounts for other sensors (green seeker, etc.) 2.4. Computing 2.4.1.Rugged laptop 2.5. Figures in this section 2.5.1. The Autonomous Prime Mover (APM) is a modified Toro e-Workman. Laser range finders on the front corners of the vehicle provide range and bearing to trees and other objects near the vehicle. 2.5.2. At left, the vehicle drives down a row at Soergel Orchards. At right, a top-down view of the laser range data from a row, with the vehicle facing upwards in the image. The lasers can see objects over 30 meters away. Due to the thinness of the canopy, the sensors see into multiple rows. 3. Autonomy software 3.1. Row following 3.1.1.Hough transform to find parallel row edges 3.1.2.Center is mid-line between edges 3.1.3.Filter to reduce jumping around 3.1.4.End-of-row detection 3.1.4.1. Know roughly how long row is 3.1.4.2. Look for gap in the edge data towards the end 3.2. Turning 3.2.1.Blind turns not good enough in narrow rows 3.2.2.Initial blind turn followed by entry detection 3.2.3.Use same row detection method 3.3. Figures in this section 3.3.1. Diagram of the software system. Range and bearing data from the laser sensors is converted into 3-D points by the obstacle detection program. The driver process uses the point data to find the row edges and steer the vehicle. A safety module checks for obstacles directly in front of the vehicle and sends a stop command if one is found. 3.3.2. At left, a graphical representation of the process of creating a Hough transform. One point in the laser data is selected, and the system records a number of potential lines (“votes”) that could go through that point. In the middle, after vote lines have been drawn for all points, two of the vote lines dominate the image. On the right, the vote matrix used by the row detector, in which lines are represented by their radius and angle from the vehicle. Height indicates the number of votes for that line. There are two peaks in the matrix, corresponding to the two dominant lines in the image. These are the edge lines selected by the row detector. 3.3.3. The autonomous system has used the Hough transform to detect a pair of parallel lines in the laser data. These parallel lines indicate the rows of trees. The system constructs the path for the vehicle to follow, indicated by the white line, located midway between the two edges. Ground points 3.3.4. In this case, the terrain is sloped such that the ground intersects with the laser plane. The ground shows up in the range data (circled in green). These points interfere with the row detection (blue and yellow lines), which no longer aligns with the trees. The white line is the filtered row center, which resists the bad detection. 3.3.5. As the vehicle turns towards the next row, the row detector finds the row. This accounts for vehicle localization errors and errors in the intended layout of the orchard. 4. Tests and demonstrations of the APM 4.1. Tested at Soergel, FREC, Sunrise, and Valley Fruit 4.2. Overall 130 km of travel in the first year 4.3. Row following performed well at all orchards 4.3.1.Some bad detections due to large terrain changes 4.4. Row entry detection performed well in orchards with sparse canopy 4.4.1.Lower success rate at Valley Fruit, with dense canopy 4.5. Demonstration of application 4.6. Figures in this section 4.6.1.APM tests (maybe just one figure with all four images?) 4.6.1.1. At the Penn State Fruit Research and Extension Center, the APM cuts the grass of an orchard block by towing a mower attachment. 4.6.1.2. The APM carries a WeedSeeker, demonstrating autonomous spraying applications. 4.6.1.3. The APM traverses a complete block at Sunrise Orchards, near Wenatchee, Washington. 4.6.1.4. At Valley Fruit Orchards near Royal City, Washington, we demonstrated autonomous crop load scouting. The APM towed the Newton, a camera-based apple-detection platform developed by Vision Robotics. The autonomous system on the APM provided localization information to the Newton, allowing Vision Robotics to map the location of apples in the orchard. 4.6.2. Entering a row in three different orchards. The green arrow indicates the row the APM is attempting to enter. At left, the trees at Soergel Orchards are young, with small trunks and very sparse canopy; the row detector must work with little information. Also, unmaintained vegetation grows in the vehicle’s path, obscuring the row. In the middle, the trees at Sunrise Orchards have sparse canopy, but their trunks are larger and more easily detected. The row detector has no problems here. At right, the trees at Valley Fruit have a canopy so dense that the APM can not see into the row it is trying to enter. The row detector can not find two parallel lines in this data. 4.6.3. We have modified an N. Blosi platform to use our software suite for autonomous orchard operations. The platform has two Sick laser range sensors in a configuration similar to those on the APM. It also has steering and distance encoders, as on the APM. 5. Current/Future work 5.1. Developing and demonstrating new applications with NBlosi 5.2. Increasing reliability of row following and turning 5.3. User interface creation 5.4. Figures in this section 5.4.1. We are attempting to develop new algorithms for row following which are more robust to uneven terrain. 5.4.2. A worker at a commercial orchard uses a newly designed interface to control the APM. 5.4.3. We have modified an N. Blosi platform to use our software suite for autonomous orchard operations. The platform has two Sick laser range sensors in a configuration similar to those on the APM. It also has steering and distance encoders, as on the APM. 6. Conclusions 6.1. Created software suite to autonomously drive a vehicle in an orchard 6.2. Completed 130 km of travel and demonstrated a variety of applications on an all-purpose vehicle 6.3. Future work on reliability and usability, and extending the software to other vehicles