API-SPEC-16D-Section-4-Accummulator-Bottles-and

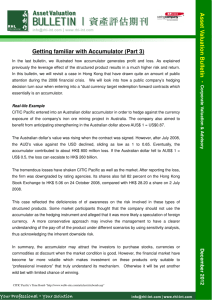

advertisement

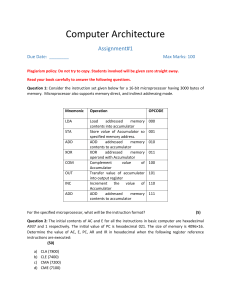

API SPEC 16D Section 4.3 4.3.1 Pressure Containing Components. 4.3.1.1 Pressure Vessels. General - Pressure vessels having internal or external operating pressures above 15 psi (103 KPa) shall meet or exceed the mandatory appendices of ASME Boiler and Pressure Vessel Code, Section VIII, Division I, Rules for Construction of Pressure Vessels. 4.3.1.1.1 Accumulators. Accumulator shells shall be hydrostatically tested to one and one-half (l-l/2) times their maximum intended working pressure. Certification of hydrostatic test witnessed by the ASME inspector shall be evident by the appropriate code inspection stamp permanently affixed to each accumulator shell. Accumulator shells shall include a permanently afilxed serial number. Written test reports certifying acceptance of the accumulator shell test shall be maintained by the control system manufacturer for each serial numbered unit. Traceability to the original accumulator shell manufacturer shall be maintained. Each precharged accumulator bottle inclusive of all components in the final configuration assembly item shall be hydrostatically tested to the maximum rated working pressure. The control system manufacturer shall maintain a Quality History File including Hydrostatic Test Charts to insure proof that each serial numbered unit successfully held the test pressure (within 1.5%) for a minimum of five minutes after stabilization (see 3.1.2.1). Sufficient time for pressure stabilization should be allowed to compensate for the temperature effect on the nitrogen precharge. 6.1.2 Personnel Qualifications. Quality assurance/ control personnel shall be qualified by relevant training and experience. Verification of qualification in written record shall be maintained and available as audit may demand. Quality assurancelcontrol personnel shall have additionally received training and shall have demonstrated a thorough understanding of the requirements and specifications of the equipment, processes, and functions under their jurisdiction. 6.1.3 Quality Control Requirements. 6.1.3.1 Organization/Procedures. The quality program shall adhere to procedures and guidelines which shall be available in written form to all quality personnel. The quality program shall include a quality manual approved by a responsible officer of the manufacturer.

![4 5877442610322214808[1]](http://s1.studylib.net/store/data/025870175_1-220d9fedd571d6f4912f0d738c694dd0-300x300.png)