Numerical investigation of an absorption

advertisement

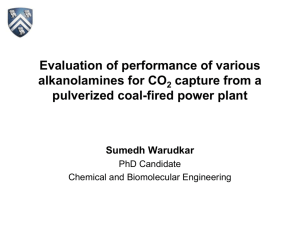

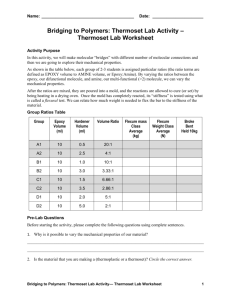

Numerical investigation of an absorption-stripping loop with different amine based solvents N. Hüser, E.Y. Kenig University of Paderborn, Faculty of Mechanical Engineering, Chair of Fluid Process Engineering, Pohlweg 55, D-33098 Paderborn, Germany Carbon dioxide (CO2) is a major Greenhouse gas responsible for global warming, and hence, much effort is being put on the development of technologies for its capture from process gas streams. When integrating amine scrubbers into a power plant, the energy requirements would increase by 25-40% [1]. Nevertheless, amine scrubbing appears to be most suitable and will probably remain the dominating technology for CO2 capture from coal-fired power plants in 2030 [2]. Many amine based solvents (e.g., amine blends, activated amines, sterically hindered amines) are reported to be advantageous with respect to reduced energy consumption, but they have not been tested in an entire absorption-desorption loop yet. In this study, different promising amine based solvents and solvent blends available in the open literature are numerically investigated as candidate absorbents for efficient CO2 capture. The main focus is to compare the process costs (energy, solvents) for the entire absorption-stripping loop with different absorbents to the costs of the commonly used monoethanolamine based CO2 capturing process. Numerical investigations are carried out using the rate-based modelling approach developed in an earlier work [3]. The model is implemented into the commercial software Aspen Custom Modeler® and adapted to various process and reaction conditions. Physical properties are determined with the help of the software package Aspen Properties®. For the evaluation of the necessary mass transfer coefficients, the volumetric hold-up and the pressure drop correlations of Billet and Schultes [4] are used, the specific gas-liquid interfacial area is estimated according to Tsai et al. [5]. Simulations are performed for flue gas conditions of coal-fired (12-16 mol% CO2) and gas-fired (3-5 mol% CO2) power plants. The results of such simulations help to identify optimal solvents for CO2 absorption without additional experimental effort. [1] D.M. D’Alessandro, B. Smit and J.R. Long, Carbon Dioxide Capture: Prospects for New Materials, Angew. Chem. Int. Ed. 49 (2010) 6058-6082. [2] G.T. Rochelle, Amine Scrubbing for CO2 Capture, Science 325 (2009) 1652-1654. [3] B. Huepen and E.Y. Kenig, Rigorous Modeling and Simulation of an Absorption-Stripping Loop for the Removal of Acid Gases, Ind. Eng. Chem. Res. 49 (2010) 772-779. [4] R. Billet and M. Schultes, Prediction of Mass Transfer Columns with Dumped and Arranged Packings – Updated Summary of the Calculation Method of Billet and Schultes, Trans. IChemE 77 (1999) 498-504. [5] R.E. Tsai, A.F. Seibert, R.B. Eldridge and G.T. Rochelle, A Dimensionless Model for Predicting the Mass-Transfer Area of Structured Packing, AIChE Journal 57 (2011) 11731184.