elec tronic supplementary material Assessing and Managing Life

advertisement

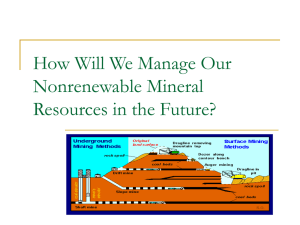

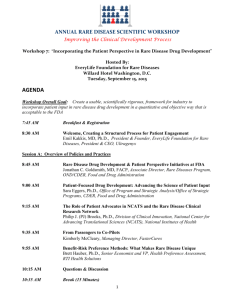

1 ELEC TRONIC SUPPLEMENTARY MATERIAL ASSESSING AND MANAGING LIFE CYCLES OF ELECTRIC VEHICLES Environmental impact of traction electric motors for electric vehicles applications Maria Hernandez1 • Maarten Messagie1 • Omar Hegazy1 • Luca Marengo2 • Oliver Winter3 • Joeri Van Mierlo1 Received: 29 January 2015 / Accepted: 24 September 2015 © Springer-Verlag Berlin Heidelberg 2015 Responsible editor: Steven B. Young 1 Vrije Universiteit Brussel, Faculty of Engineering, Mobility and Automotive Technology Research Group (MOBI), Pleinlaan 2, 1050 Brussels, Belgium 2 Centro Richerche Fiat S.C.p.A, R&D Product Development, Strada Torino 50, 10043 Orbassano (TO), Italy 3 AIT Austrian Institute of Technology GmbH, Mobility Department Electric Drive Technologies, 1210 Vienna, Austria Maria Hernandez mahernan@vub.ac.be 2 Index Production of rare earth elements…………………………………………………………………………2 Environmental concerns in the production of REE………………………………………………..5 Assumptions in the production of REE magnets….......................................................................6 List of tables Table 1 Mass of materials (NdFeB permanent magnet) Table 2 Inputs in magnet manufacturing process Production of rare earth elements Rare earth elements (REEs) are a group of 15 chemical elements in the periodic table: cerium (Ce), dysprosium (Dy), erbium (Er), europium (Eu), gadolinium (Gd), holmium (Ho), lanthanum (La), lutetium (Lu), neodymium (Nd), praseodymium (Pr), promethium (Pm), samarium (Sm), scandium (Sc), terbium (Tb),thulium (Tm), ytterbium (Yb) and yttrium (Y). Due to their strong affinity with oxygen, REEs are primarily present as oxidic compounds. These elements are part of important components of many emerging technologies and products, such as electric and hybrid vehicles, wind turbines, and cell phones. Given this increasing global demand for green and sustainable products in transport, energy production and manufacturing industries, REE demand throughout the world is expected to increase. For the moment, the production of rare earth oxides (or REOs) is highly concentrated in China, and so it is the market for REOs, well consolidated in this one region of the world. In consideration of this, the modelling in the study, ore types and processes for extraction of Rare earth element (REE), processing and final manufacturing of REE magnets, will follow the practices used in China. 3 Rare earth elements are not available as elemental metals in nature, but they take part in a host mineral’s chemistry. For this reason the extraction and production of REE can be complex, as it requires the separation and break down of the material for the extracted mineral ore. Four principal stages can be identified in the extraction and processing of REEs: (1) mining; (2) beneficiation processes; (3) extraction processes; and (4) reduction. In our study these stages are modeled using Ecoinvent V2.2 database. The processes included by the database and their description, summarized from EPA (2012), are explained below: 1) Mining The methods used for mining of REE are in principle the same ones used for the extraction of other metal ores, namely surface or underground mining in hard rock, or in situ leaching. The method selected for the extraction of the mineral will depend on the conditions (size and location of deposit), the type of mineral ore, and the variety of accompanying elements that can be extracted simultaneously. Reference EPA (2012) Rare Earth Elements: A Review of Production, Processing, Recycling, and Associated Environmental Issues. EPA 600/R-12/572. The two most common mining methods used are described: In Situ Leach Mining: this is a method used commonly when the metal deposit is deep or whenthe ore grade is low. It consists of the injection of fluids such as, water, acids or other chemicals through a circuit of drilled boreholes caved around the mineral deposit. An ore containing solution is then pumped from the deposit, which is then processed with a solvent extraction method in order to recover the valuable metals. Surface and Underground Mining: as for other conventional metals, surface and underground mining for REEs, involves the use of explosive, excavators and drilling equipment and removal equipment for waste rock and ore material. Underground and open-pit mining are the more conventional methods used in the hardrock mining industry, and they both generate large amounts of overburden piles and waste rocks, that in some cases may be used as coproduct for other industries. 4 From the mining activities, two major mineral sources of REEs are obtained: bastnasite and monazite. There is a wide variety of minerals from which REEs can be obtained, including xenotime, apatite, yttrofluorite, cerite, and gadolinite, however they areless common. In this study, the process includes material and energy input, emissions and land use for the open-pit mining, and extraction of bastnasite ore, with a rare earth oxide concentration of 6 %, as similar to conditions in China. Transport and infrastructure required are also included. Fig. 1 shows a representation of mining process, and waste managementassociated, until the final processing of REO concentrate: Figure S1 Conventional hardrock resource processing and potential wastes Mining Mine water Overburden Waste rock Sub-ore Stockpile Ore Stockpile Grinding Flotation Tailings Acid digestion Thickening Rare earth Drying REO concentrate separations Liquid wastes Product managementunit Process Waste management 5 (excluding emissions) diagram (Source: EPA 2012) 2) Beneficiation Processes The beneficiation process involves the separation of the rare earth elements from the mineral (bastnasite and monazite), without modifying the chemical composition of the ore. Normally iron and other less valuable minerals are separate. Crushing and grinding steps enable the grains of various minerals to be separated from each other. Later separation processes typically employed include (1) gravity separators, (2) electrical/magnetic separators, and (3) flotation separators. The end result of the beneficiation process is a concentrate containing high percentages of rare earth bearing minerals. We have considered for this study mineral concentration by flotation separation process, obtaining rare earth concentrate product with 70 % rare earth oxide. 3) Extraction Processes Hydrometallurgy, pyrometallurgy and electrometallurgy are three rare earth extraction methods used, hydrometallurgy being the most common chemical extraction method of separating individual REOs from the mineral concentrate. Leaching, extraction, and precipitation are typical hydrometallurgy techniques that allow the separation of mineral concentrates until the obtaining of usable rare earth oxides. Basicity differences between the various rare earths allow the further separation by fractional crystallization, fractional precipitation, ion exchange, and solvent extraction from which the individual REOs are obtained. Although some of the individual co-products (REOs and rare earth chlorides resulting from these processes) have market value, further processing and refining are required to produce high-quality pure metal end products to maximize value. This study includes leaching process using HCL. It includes roasting and cracking of the rare earth concentrate with 98 % sulphuric acid, as used in China. For the following separation of the different rare earth oxides solvent extraction is used. 4) Reduction Processes Further processing by techniques such as metallothermic reduction can refine the oxides or metal mixtures into high-purity REMs. Due to their high stability further purification of REOs can be difficult to achieve. Several methods have been developed to accomplish this task. The three primary methods of producing rare earth metals are (1) reduction of anhydrous chlorides or fluorides, (2) reduction of REOs, and (3) fused salt electrolysis of rare earth 6 chlorides or oxide-fluoride mixtures. In our study reduction of REOs is considered and the obtained rare earth oxide final product has a purity of up to 99.9 %. Environmental concerns in the extraction of REE The main environmental concerns of REE extraction and early processing have being associated to the mining activities for the metals, and particularly the emissions and wastes generated during this activities due to improper treatment and disposal. These emissions typically contain high-surface-area particles, wastewater, and process chemicals. In normal conditions these agents can be adequately control and managed, however in impoundment areas, exposed to weathering conditions, they have the potential to contaminate the air, soil, surface, and groundwater. Typical pollutants that have been associated with rare earth extraction and processing are: - ore-associated metals (e.g., aluminum, arsenic, barium, beryllium, cadmium, copper, lead, manganese, zinc); - radionuclides; - radon; - fluorides; - sulfates; Fugitive dust can contaminate the air and surrounding soil. Similarly, surface water runoff from precipitation events can transport pollutants from the impoundment to surrounding soil and surface waterbodies, or contamination of surrounding groundwater resources. However, these situations can be prevented with adequate management of mining and the set in place of remediation techniques for pollution control. Assumptions in the production of REE Magnets For the production of the magnet, we consider a stoichiometric composition of the magnet in order to estimate the amount neodymium oxide, boric oxide and iron necessary for the manufacturing. The magnet will have a nickel coating assumed to be equivalent to 10% of the total weight of the magnet. Table S1 Molecule Nd2Fe14B Nd2O3 Mass of materials (NdFeB permanent magnet) Moles Weight (%) 1 1 31.12 Mass (kg) Material 1 Neodymium magnet 0.3112 Neodymium oxide 7 B2O3 Fe Table S2 0,5 14 3.22 72.32 0.0322 Boric oxide 0.7232 Iron Inputs in magnet manufacturing process Data Neodymium oxide Pig iron Boric oxide Nickel coating Electricity, medium voltage, at grid, CN Unit Kg Kg Kg Kg kWh Amount Remarks 0.68 1.59 0.07 0.25 15.25