polb23941-sup-0001-suppinfo01

advertisement

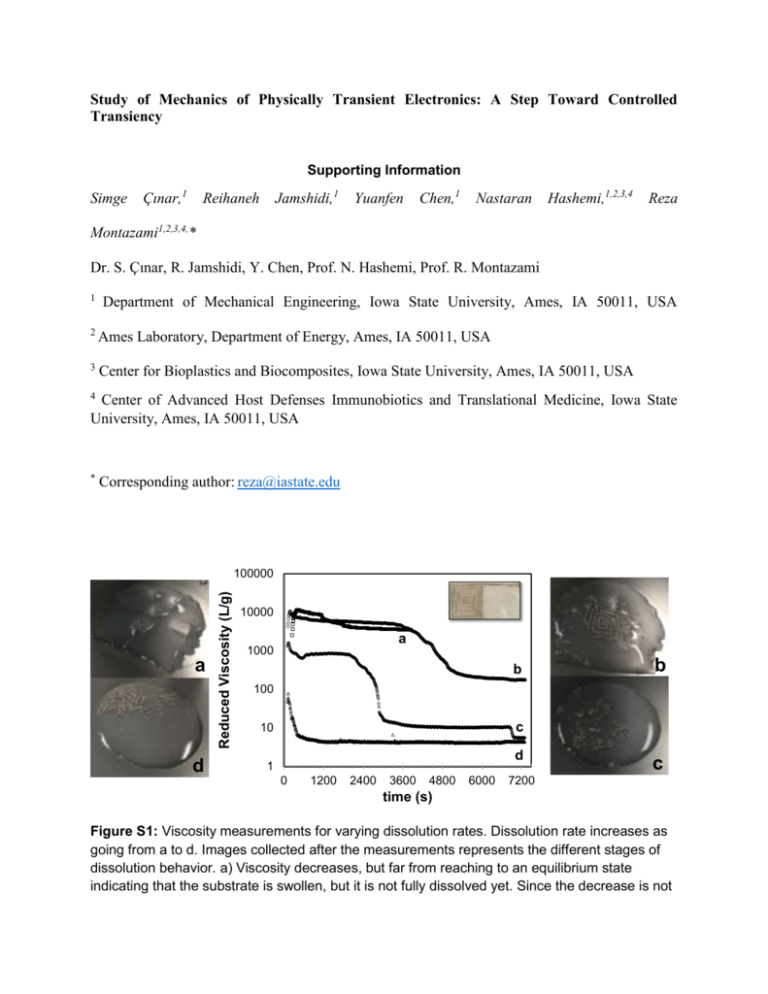

Study of Mechanics of Physically Transient Electronics: A Step Toward Controlled Transiency Supporting Information Simge Çınar,1 Jamshidi,1 Reihaneh Yuanfen Chen,1 Nastaran Hashemi,1,2,3,4 Reza Montazami1,2,3,4,* Dr. S. Çınar, R. Jamshidi, Y. Chen, Prof. N. Hashemi, Prof. R. Montazami 1 Department of Mechanical Engineering, Iowa State University, Ames, IA 50011, USA 2 Ames Laboratory, Department of Energy, Ames, IA 50011, USA 3 Center for Bioplastics and Biocomposites, Iowa State University, Ames, IA 50011, USA 4 Center of Advanced Host Defenses Immunobiotics and Translational Medicine, Iowa State University, Ames, IA 50011, USA * Corresponding author: reza@iastate.edu a d Reduced Viscosity (L/g) 100000 10000 a 1000 b b 100 c 10 d 1 0 1200 2400 3600 4800 6000 c 7200 time (s) Figure S1: Viscosity measurements for varying dissolution rates. Dissolution rate increases as going from a to d. Images collected after the measurements represents the different stages of dissolution behavior. a) Viscosity decreases, but far from reaching to an equilibrium state indicating that the substrate is swollen, but it is not fully dissolved yet. Since the decrease is not a steep one, the dissolution appears to be very slow. In this specific case, since the dissolution of PVA and its composites with sucrose are known to be much faster, the dissolution rate is slowed down because of the experimental conditions, lack of enough solvent to complete dissolution. b) Substrate is swollen greatly, but not fully dissolved. The circuit is disconnected, but not re-dispersed to individual particles yet. c) Viscosity decreased to very low values after two transition states and reached to its equilibrium. Dissolution of substrate is completed, and the circuit is completely re-dispersed to colloidal particles. Device is fully degraded. d) Only one transition observed at the very beginning of the experiment without showing any other equilibrium state. Dissolution of substrate is completed too fast before allowing the circuit to redisperse. The results justify that the viscosity measurement involves critical information and can be used in investigation of the dissolution behavior of polymer substrates and devices. An example for as prepared device is presented inset. η0 ηbp tbp Figure S2: Parameters defined for dissolution behavior. Table S1: Critical parameters for dissolution behavior of substrates with varying concentration and its devices. Values were obtained from viscosity measurements. η0 (L/g) tbp (s) ηbp (L/g) Sample (PVA:Sucrose) Substrate Device Substrate Device Substrate Device 1:0 2000 ± 600 2370 ± 710 653 ± 130 7880 ± 1575 3.7 ± 1.1 47.0 ± 14.0 10:1 465 ± 140 860 ± 260 220 ± 45 1355 ± 270 1.7 ± 0.5 4.1 ± 1.2 2:1 1085 ± 325 3050 ± 915 100 ± 20 640 ± 130 1.2 ± 0.4 4.2 ± 1.3 1:1 245 ± 75 750 ± 225 72 ± 15 180 ± 35 1.3 ± 0.4 5.2 ± 1.6 1:2 295 ± 90 695 ± 210 15 ± 3 115 ± 20 0.32 ± 0.10 1.4 ± 0.4 Transmittance (%) tbp is the break-point time for system transiency, η0 is the initial reduced viscosity and ηbp is the reduced break-point viscosity. 1:0 10:1 2:1 1:1 1:2 1710 1650 2940-2910 14151329 1142 2990-3700 832 1088 923 1045 991 3650 3150 2650 2150 1650 -1 Wavenumber (cm ) 1150 650 Figure S3: Increasing crystallinity of the PVA/Sucrose composite substrates – ATR-FTIR Spectra Table S2: Chemical assignments of IR peaks for PVA – sucrose films [1]. Band (cm-1) Assignment PVA or Sucrose 2990 – 3700 (very broad) inter-, intramolecular H- bands both 2940 – 2910 (doublet) C-H stretching both 1710 1650 ν C=O (OH groups of PVA) 1720, 1735-1750 Deformation vibration of the adsorbed water molecules PVA PVA CH2 (PVA) 1415 δ C-O-H (1431, 1440 sucrose) δ C-O-H (glucose part of sucrose) δ C-O-H (fructose part of sucrose) PVA - sucrose 1267, 1236 τ CH2 PVA 1142 (shoulder) symmetric C-C stretching mode PVA (semicrystalline PVA) 1088 -C-O groups PVA 1045 ν C-O exo (1052, 1008) sucrose 991 δ C-O-H sucrose 917 – 923 ν C-C (911 fructose, 941 glucose) sucrose 837 ν C-C PVA 832 – 850 ν C-C (867, 849) sucrose 1377 1329 sucrose sucrose References [1] S. K. Mallapragada, N. A. Peppas, Journal of Polymer Science Part B: Polymer Physics 1996, 34, 1339; H. S. Mansur, C. M. Sadahira, A. N. Souza, A. A. P. Mansur, Materials Science and Engineering: C 2008, 28, 539; J.-J. Max, C. Chapados, The Journal of Physical Chemistry A 2001, 105, 10681.