2. Analysis of wear scars with atomic force microscopy

advertisement

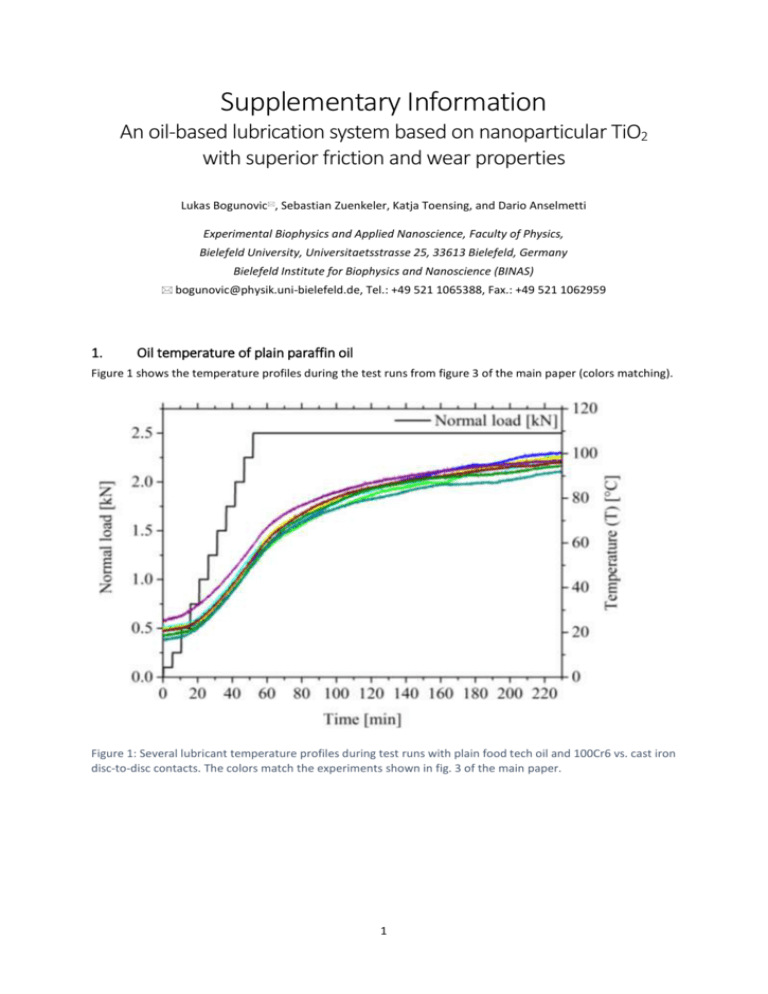

Supplementary Information An oil-based lubrication system based on nanoparticular TiO2 with superior friction and wear properties Lukas Bogunovic, Sebastian Zuenkeler, Katja Toensing, and Dario Anselmetti Experimental Biophysics and Applied Nanoscience, Faculty of Physics, Bielefeld University, Universitaetsstrasse 25, 33613 Bielefeld, Germany Bielefeld Institute for Biophysics and Nanoscience (BINAS) bogunovic@physik.uni-bielefeld.de, Tel.: +49 521 1065388, Fax.: +49 521 1062959 1. Oil temperature of plain paraffin oil Figure 1 shows the temperature profiles during the test runs from figure 3 of the main paper (colors matching). Figure 1: Several lubricant temperature profiles during test runs with plain food tech oil and 100Cr6 vs. cast iron disc-to-disc contacts. The colors match the experiments shown in fig. 3 of the main paper. 1 2. Analysis of wear scars with atomic force microscopy Figure 2 a) shows a typical image of the used disc-to-disc contact that was also microscopically analyzed in figure 4 of the main paper. The claimed smoothing of the 100Cr6 disc is also proofed by the atomic force microscopy image in b). Figure 2: a) Photograph of a disc pair after a test run with food tech oil. b) The atomic force microscopy image of the surface in a wear scar of a 100Cr6 discs shows a mean roughness of 𝑅𝑎 = 25.0 nm. 3. Dynamic viscosity of our formulation Table 1 shows dynamic viscosity data of our fully formulated lubricant in dependence of the T805 TiO2 nanoparticle concentration. The results tend to increase with increasing concentration. However, no significant influence on the friction coefficients is notable (compare Fig. 11 of the main paper). Table 1: Dynamic viscosity at 20 °C and 40 °C in [mPa s] in dependence of the T805 TiO2 nanoparticle concentration supplemented to food tech oil and 15 wt% oleylamine and Pluronic® RPE2520 in relation to the particle concentration. The Estisol® 242 concentration is equal to the particle concentration except for the values at 1% and 5%, where the Estisol® concentration is only one half of the particle concentration. T805 concentration 𝜼 @ 𝟐𝟎 °𝐂 𝜼 @ 𝟒𝟎 °𝐂 0 wt% 0.01 wt% 0.05 wt% 0.1 wt% 0.2 wt% 0.5 wt% 1 wt% 2 wt% 5 wt% 198 199,8 199,8 197,4 198,6 197,4 198 201,1 215,9 63,5 64,1 64,1 63,5 62,3 64,1 64,1 64,1 70,9 2