Autoclaving and Microscopy

advertisement

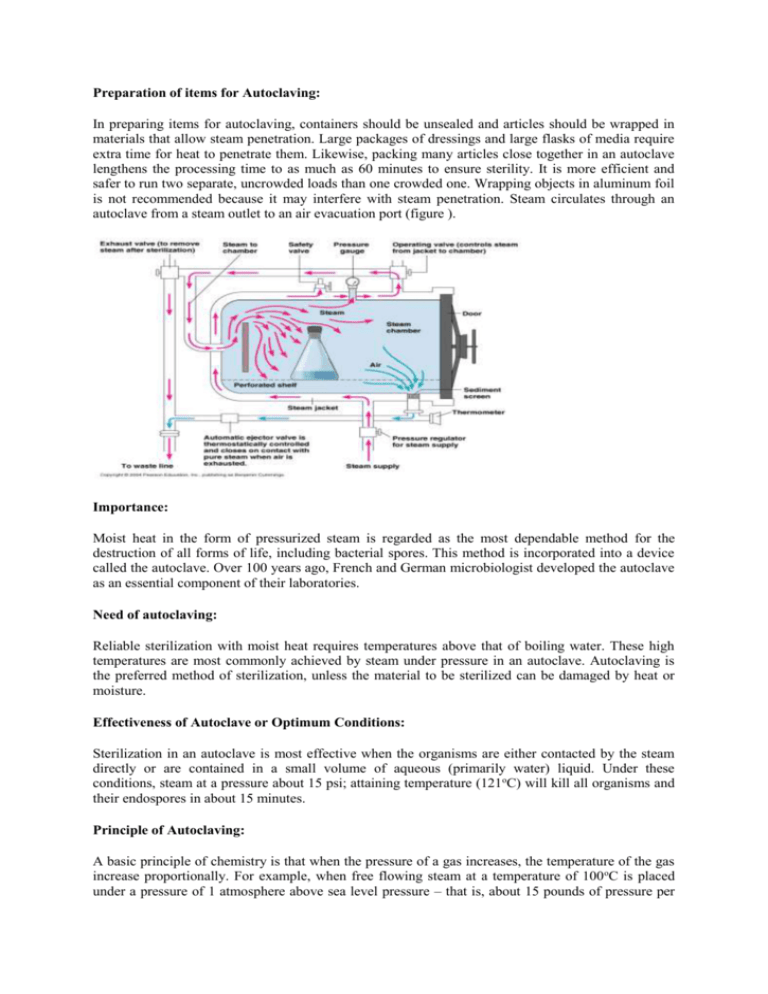

Preparation of items for Autoclaving: In preparing items for autoclaving, containers should be unsealed and articles should be wrapped in materials that allow steam penetration. Large packages of dressings and large flasks of media require extra time for heat to penetrate them. Likewise, packing many articles close together in an autoclave lengthens the processing time to as much as 60 minutes to ensure sterility. It is more efficient and safer to run two separate, uncrowded loads than one crowded one. Wrapping objects in aluminum foil is not recommended because it may interfere with steam penetration. Steam circulates through an autoclave from a steam outlet to an air evacuation port (figure ). Importance: Moist heat in the form of pressurized steam is regarded as the most dependable method for the destruction of all forms of life, including bacterial spores. This method is incorporated into a device called the autoclave. Over 100 years ago, French and German microbiologist developed the autoclave as an essential component of their laboratories. Need of autoclaving: Reliable sterilization with moist heat requires temperatures above that of boiling water. These high temperatures are most commonly achieved by steam under pressure in an autoclave. Autoclaving is the preferred method of sterilization, unless the material to be sterilized can be damaged by heat or moisture. Effectiveness of Autoclave or Optimum Conditions: Sterilization in an autoclave is most effective when the organisms are either contacted by the steam directly or are contained in a small volume of aqueous (primarily water) liquid. Under these conditions, steam at a pressure about 15 psi; attaining temperature (121oC) will kill all organisms and their endospores in about 15 minutes. Principle of Autoclaving: A basic principle of chemistry is that when the pressure of a gas increases, the temperature of the gas increase proportionally. For example, when free flowing steam at a temperature of 100 oC is placed under a pressure of 1 atmosphere above sea level pressure – that is, about 15 pounds of pressure per square inch (Psi) --- the temperature rises to 121oC. Increasing the pressure to 20 psi raises the temperature to 126oC. The relationship between temperature and pressure is shown in table 2. In this way steam is a gas, increasing its pressure in a closed system increases its temperature. As the water molecules in steam become more energized, their penetration increases substantially. This principle is used to reduce cooking time in the home pressure cooker and to reduce sterilizing time in the autoclave. It is important to note that the sterilizing agent is the moist heat, not the pressure. Table The Relationship Between the Pressure and Temperature of Steam at Sea Level* Pressure (psi in excess of atmospheric Temperature (oC) pressure) 0 psi 100 5 psi 110 10 psi 116 15 psi 121 20 psi 126 30 psi 135 Rules implied for Autoclaving: Sterilization by autoclaving is invariably successful if properly done and if two common-sense rules are followed: First, articles should be placed in the autoclave so that steam can easily penetrate them. Second, air should be evacuated so that the chamber fills with steam. Working of Autoclave: Most autoclaves contain a sterilizing chamber into which articles are place and a steam jacket where steam is maintained. As steam flows from the steam jacket into the sterilizing chamber, cool air is forced out and a special valve increases the pressure to 15 pounds/square inch above normal atmospheric pressure. The temperature rises to 121.5oC, and the superheated water molecules rapidly conduct heat into microorganisms. The time for destruction of the most resistant bacterial spore is now reduced to about 15 minutes. For denser objects, up to 30 minutes of exposure may be required. The conditions must be carefully controlled or serious problems may occur. Uses of Autoclave: Autoclaving is used to sterilize culture media, instruments, dressings, intravenous equipment, applicators, solutions, syringes, transfusion equipment, and numerous other items that can withstand high temperatures and pressures. The laboratory technician uses it to sterilize bacteriological media and destroy pathogenic cultures. The autoclave is equally valuable for glassware and metalware, and is among the first instruments ordered when a microbiology laboratory is established. Autoclaves are also used on large industrial scale. Large industrial autoclaves are called retorts, but the same principle applies for common household pressure cooker used in the home canning of foods Limitations and Disadvantages of Autoclave: The autoclave also has certain limitations. For example, some plasticware melts in the high heat, and sharp instruments often become dull. Moreover, many chemicals breakdown during the sterilization process and oily substances cannot be treated because they do not mix with water. Heat requires extra time to reach the center of solid materials, such as caned meats, because such materials do not develop the efficient heat-distributing convection currents that occur in liquids. Heating large containers also requires extra time. Table 3 shows the different time requirements for sterilizing liquids in various container sizes. Unlike sterilizing aqueous solutions, sterilizing the surface of a solid requires that steam actually contact it. Table 3 Container Size Test Tube: The effect of Container Size on Autoclve Sterilization Times for Liquid Solutions* Liquid Volume Sterilization Time (min) 10 ml 15 95 ml 15 1500 ml 30 6750 ml 70 18×150 mm Erlenmeyer Flask: 125 ml Erlenmeyer Flask: 2000 ml Fermentation Bottle: 9000 ml Indicator of Sterilization Achievement: Several commercially available methods can indicate whether sterilization has been achieved by heat treatment. Modern autoclaves have devices to maintain proper pressure and record internal temperature during operations. Regardless of the presence of such a device, the operator should check pressure periodically and maintain the appropriate pressure. Chemical reactions in which an indicator changes color when the proper times and temperatures have been reached. In some designs, the word "sterile" or "autoclaved" appears on wrappings or tapes. These tapes are not fully reliable because they do not indicate how long appropriate conditions were maintained. Tapes or other sterilization indicators should be placed inside and near the center of large packages of determine whether heat penetrated them. In another method, a pellet contained within a glass vial melts. A widely used test consists of preparations of specified species of bacterial endospores such as Bacillus stearothermophilus, impregnated into paper strips. The spore strip and an ampule of medium are enclosed in a soft plastic vial. The vial is placed in the center of the material to be sterilized and is autoclaved. After autoclaving, these can then be aseptically inoculated into culture media. Growth in the culture media indicates survival of the endospores and therefore inadequate processing. Other designs use endospore suspensions that can be released, after heating, into a surrounding culture medium within medium within the same vial. Important Points to Remember For Autoclaving: Steam under pressure fails to sterilize when the air is not completely exhausted. This can happen with the premature closing of autoclave's automatic ejector valve. The principles of heat sterilization have a direct bearing on home canning. To sterilize dry glassware, bandages, and the like, care must be taken to ensure that steam contacts all surfaces. For example, aluminum foil is impervious to steam and should not be used to wrap dry materials that are to be sterilized; paper should be used instead. Care should also be taken to avoid trapping air In the bottom of a dry container because trapped air will not be replaced by steam, which is lighter than air. The trapped air is the equivalent of a small hot-air oven, which, as we will see shortly, requires a higher temperature and longer time to sterilize materials. Containers that can trap air should be placed in a tipped position so that the steam will force out the air. Products that do not permit penetration by moisture, such as mineral oil or petroleum jelly, are not sterilized by the same methods that would sterilize aqueous solutions. This precaution is necessary because when an object is exposed to heat, its surface becomes hot much more quickly than its center. (When a large piece of meat is roasted, for example, the surface can be well done while the center remains rare.) Prevacuum Autoclave: In large laboratories and hospitals, where great quantities of materials must be sterilized, special autoclaves, called prevacuum autoclaves, are often used. This machine draws air out of the sterilizing chamber at the beginning of the cycle. Saturated steam is then used at a temperature of 132 oC to 134oC at a pressure of 28 to 30 lb/in2. The time for sterilization is now reduced to as little as 4 minutes. A vacuum pump operates at the end of the cycle to remove the steam and dry the load. The major advantages of the prevacuum autoclave are the minimal exposure time for sterilization, the reduced time to complete the cycle and the costs of sterilization are greatly decreased. The Autoclave The autoclave uses high pressure and high temperature steam to effectively kill microorganisms or render a biohazardous material inactive. For effective sterilization, the materials/load must be saturated with this steam. Air pockets or insufficient steam supply will prevent effective decontamination. The potential risks of using an autoclave are heat and steam burns, hot fluid scalds, injuries to hands and arms from the door, or bodily injury in the event of an explosion. Additional injury or exposure to biohazardous material may be incurred if the contents of the biohazardous waste are packaged improperly. Onsite training on how to use the autoclave properly and safely is essential for all new employees to prevent injury. The use of heat-insulating gloves, lab coat and closed-toe shoes will help prevent burns and scalds during loading and unloading. If a load of biohazardous waste is inadequately autoclaved, there is potential for human and environmental exposure to biohazardous materials. If you have never operated the autoclave you will be using, contact an experienced user in your laboratory for instruction on safe operation. For building autoclaves, you may need to contact the facilities manager or department safety contact. For additional assistance, contact the Biological Safety Section 333-2755 or via e-mail. Autoclave Safety Prevent injuries when using the autoclave by observing the following: Never put volatile chemicals or solvents (alcohols, chloroform), or corrosive chemicals (bleach, acetic acid, formalin, fixed tissues etc.), or radioactive materials in an autoclave. (See below.) Wear appropriate street clothing including closed-toe shoes and Personal Protective Equipment (PPE) including a lab coat, heat resistant gloves, and eye protection especially when unloading the autoclave. Don't autoclave sealed containers as they pose an explosion risk. Never open the door to the autoclave if there is water running out the bottom. Clogged steam lines, equipment malfunction or plugged drains may cause a buildup of scalding water. Prevent steam burns and shattered glassware by making sure that the pressure in the autoclave chamber is zero and the temperature is at or below 121°C before opening the door at the end of a cycle. Make sure that no personnel, including you, are directly in front of the door. Be especially careful with liquids due to superheating, a condition that occurs when liquids are at a temperature above their normal boiling point but do not appear to be boiling. In situations where personnel are in a hurry to remove flasks or bottles from the autoclave, the superheated liquids may boil out of their containers or explode. Items that should not be processed in the autoclave include: Sharps: It is not necessary to autoclave discarded sharps (Used/unused needles and syringes, contaminated broken glass, microscope slides and coverslips, Pasteur pipettes, scalpel or razor blades) prior to disposal in a sharps disposal container. For a pick-up of full sharps containers, fill out the online form at http://www.drs.illinois.edu/sharps/. Hazardous chemicals (including items associated with hazardous chemicals): In general, do not autoclave flammable, reactive, corrosive, toxic or radioactive materials. Never autoclave dried bleach or bleach associated materials or nitrocellulose as both compounds pose a fire or explosion risk. Lab coats that have been contaminated with chemicals should not be autoclaved but cleaned by an approved laundry service or disposed of as chemical waste. To schedule a chemical waste pick-up, fill out the CWM-TRK form online at: http://www.drs.illinois.edu/css/guidesplans/wasteguide/cwmtrk.aspx?tbID=gp. Radioactive materials: Contact the DRS Radiation Safety Program for information on proper disposal of radioactive materials. To schedule a pickup, fill out a Radioactive Waste Pick-up Request available online at: http://www.drs.illinois.edu/rss/factsheets/waste.aspx Pathological waste: Includes animal carcasses, tissues and organs and human tissues and organs. University policy requires certain types of pathological waste be disposed of by incineration. For more information on how to dispose of pathological waste for incineration see: http://www.drs.illinois.edu/bss/programareas/waste/index.aspx#biologicalmaterials or e-mail bss@illinois.edu. Mixed wastes: If the biological waste also contains hazardous chemicals or radioactive materials, contact the Biological Safety Section via e-mail for assistance. LMW biotoxins, prions and autoclave resistant materials: Some biohazards (e.g. Low Molecular Weight biotoxins and prions) will not be inactivated by autoclaving as the material is extremely stable. Contact the Biological Safety Section (via e-mail) if you are disposing of these types of materials. Preparing Materials for Autoclaving To ensure adequate steam penetration, pack solid materials loosely; don't intentionally compact waste or overfill biohazardous waste bags. Bags/containers should be placed in a large, leak-proof, shallow pan to avoid or contain spills. Non-glass containers are recommended such as stainless steel pans or plastics (i.e. polypropylene, polypropylene copolymer or fluoropolymers) that are capable of being autoclaved repeatedly. Before processing, open the bags/containers so that the steam can penetrate and effectively raise the temperature for adequate killing. A small amount of water may be added to ensure heat transfer inside the bag/container. If the bag is closed during autoclaving, the temperature of the contents may not be raised sufficiently for decontamination. If you are processing more than one tray make sure that there is ample room between the trays so steam circulation is not impaired. Place indicator tape on the bag. Place containers of liquids (bottles, beakers, flasks etc.) covered with a cotton plug or steampenetrable bung in a large, leak-proof, shallow pan. Inspect the glass to make sure there are no cracks. Do not fill containers to the top but leave plenty of head room. Bottles with narrow necks may boil over violently if filled too full of liquid. Avoid the use of bottles if possible, but if it is necessary, make sure that the screw-cap is nearly unscrewed allowing for pressure changes or it may explode. Water should be added to the pan to help prevent heat shock to the containers. Place the pan and contents in the autoclave and put indicator tape on the containers. How to Operate an Autoclave The following are basic instructions for autoclave use but do not replace the Manufacturer's Operating Instructions and hands-on training. Before using any autoclave for the first time, read and thoroughly understand the owner's manual because many makes and models have unique characteristics. Basic Instructions 1. Place the items to be autoclaved in the chamber. 2. Check the drain screen to make sure that it is not plugged or obstructed. 3. For bench top units that do not have inline steam, check and fill reservoir with deionized water to the fill line (see manufacturer's instructions). 4. Close and seal the autoclave door. 5. On the autoclave keypad (or dials, depending on the model) select: The type of load: gravity (solid items) or liquid The sterilization time: The sterilization time will vary according to the contents and how the load is packaged and should be measured after the temperature of the materials reaches 121°C and 15 pounds per square inch (PSI) and can be variable with a minimum of 12-15 minutes. Several trays with large bags or containers loaded in the autoclave will require a longer time to reach 121°C and should be set accordingly. The sterilization temperature. Unless specifically instructed, the chamber temperature is usually set to 121°C (250°F). A dry cycle if desired, Or select a preprogrammed cycle, i.e. the “waste” cycle if your autoclave has this option. Preprogrammed cycles are either entered at the factory or by the autoclave responsible party. Check the manufacturer’s instructions or with your responsible person. 6. Run the autoclave cycle. Fill out the autoclave log if this is required. 7. At the completion of the cycle, don appropriate PPE before opening the door. Wear safety glasses, a lab coat with long sleeves, closed-toed shoes and heat-resistant gloves. 8. Open the door slowly and only slightly and allow steam to escape. 9. Allow items to cool in the autoclave for at least 10 minutes before fully opening the door. 10. Check the autoclave tape for a color change, and the print-out from the recorder to see if the time and temperature were attained. If not, the load should be re-autoclaved in another autoclave. 11. After autoclaving, any bag displaying the biohazard symbol must be over bagged with an opaque trash bag and sealed prior to disposal in the regular waste stream. Bags with the biohazard symbol, regardless of use, must not be placed in the regular waste stream without being overbagged. Autoclaving Biological Waste Generally recommended parameters for biological waste are sterilization time of 60-120 minutes (excluding exhaust time) and 250°F/121°C at 15 psi. Studies have shown that the processing time necessary to achieve decontamination of biological material depends on several loading factors. Load size, type of container, and moisture content all impact decontamination time. If the waste is packed too tightly or it is a very large load, the length of the sterilization time may need to be increased to allow the steam to penetrate the center of the load. The cycle parameters may require different settings depending on the infectious materials you are trying to decontaminate. The tighter the autoclave is packed, the longer it will take to reach 121°C in the center of the load. To assure that the material you are autoclaving is properly decontaminated/treated (killed or inactivated) add 10-15 minutes to the estimated sterilization time for over-kill. Autoclave Indicators Autoclave indicators are devices used to test the performance of an autoclave and confirm or validate that certain performance standards have been met. Chemical indicators are designed to respond with a characteristic chemical or physical change to one or more of the physical conditions within the chamber. Chemical indicators come in several forms and types. Tape indicators are a type of chemical indicator that use a heat sensitive ink which changes color from white to a visible pattern following processing, indicating that a temperature of 121°C has been achieved. If the tape fails to change color, this alerts the user that there is a problem. Note that the color change does not prove decontamination effectiveness – it only verifies that the outside of the container came to temperature, and does not reflect time or conditions inside the load. Biological indicators are composed of a standardized population of resistant bacterial spores such as Geobacillus stearothermophilus in the form of spore strips or spore suspension in prepackaged vials. They are used to determine if the sterilization cycle parameters were sufficient to kill the test microorganisms. To consistently ensure that no biological entity is surviving the autoclave process, autoclave validation with biological indicators should be performed on a regular basis. See the section on Autoclave Validation below for more information. Autoclave Validation Autoclave indicator tape should be used for every load processed in an autoclave to confirm that 121°C has been achieved. It also serves as a visible means to communicate if the material has or has not been processed. If you are generating biological waste associated with Risk Group 2 biological material, biological indicator testing should be performed monthly. A validation log of Risk Group 2 decontaminated waste should be maintained and available for review. Validation testing with biological indicators is recommended on a quarterly basis for Risk Group 1 biological waste and for other non-waste material to ensure proper autoclave performance. In general the validation process using biological indicators involves autoclaving spore vials (heatresistant bacterium Geobacillus stearothermophilus) inside representative bags of waste, incubating the spore vial according to the manufacturer’s instructions, and determining the results. Spore vials can be purchased from many distributors (see Autoclave Supplies below). The assumption is made that if the heat-resistant G. stearothermophilus spores are killed so are the microorganisms in the bag/container. Steps for autoclave validation using biological indicators 1. Obtain spore vial(s) and string (to assist in retrieving the vial after processing). Vials have expiration dates – check the date and don’t use expired vials. 2. Don PPE (gloves, lab coat) and place the vial in the bag of waste or other material near the center of the load. Tie a string around the vial and drop the vial down into the center of the material. If the string is left hanging out of the bag, you can easily remove the vial after autoclaving. 3. Autoclave material as usual, and allow it to cool. 4. Retrieve the vial. Do not dispose of the test load until the validation test is completed and passed. 5. Allow the vial to cool for at least 10 minutes. Caution: The vial is hot and under pressure. Failure to allow sufficient cooling time may result in an injury if the vial bursts. 6. Crush the vial in the tool provided by the manufacturer. 7. Incubate the autoclaved tube and a positive control tube (one that wasn't autoclaved) in a heat block or incubator at 55°C for the time period recommended by the manufacturer of the spore vial. 8. After the appropriate incubation time, read the color. The control vial should exhibit a color change (typically to yellow, may vary by manufacturer). If the control vial does not exhibit growth via a color change, the spores are not viable and the test is considered invalid. The autoclaved vial should exhibit no growth and retain the original color prior to processing. If spore growth is exhibited - the autoclaved vial changes color or the liquid becomes turbid the autoclave has failed to sterilize the load and the test must be repeated. Test failure If test results indicate that the autoclave failed to kill the spores, first check the recorder chart to make sure the correct temperature and cycle time were obtained. If the correct time and temperature were achieved in your initial test, and the autoclaved spore vial exhibited growth, you will need to change one or more of these parameters when you re-autoclave: Time: Increase the cycle time by 15 minutes and insert another vial to do a retest. If your results are positive again, increase the cycle time by 15 minutes increments until the results are negative. Reminder: The cycle time required will vary with the composition of the load. Density: Load the bag to 75% of the holding capacity or less. Don’t compress waste to fit more in the bag, because steam cannot penetrate completely through densely packed waste bags. Steam: Add approximately one half cup of water to your dry waste loads to facilitate steam generation. Loading techniques: You may wish to try changing how you load the autoclave to allow steam to better move from the top of the chamber to the bottom and penetrate the load. a. Place bags in the back of the autoclave rather than in the front of the autoclave, which is the coldest part of the chamber. b. Avoid crowding or stacking. c. Check that the bags are not touching the top or sides of the autoclave as you push the tray inside. d. Try using shallower trays (but make sure the tray will still contain any spills). Autoclave Repair If an autoclave in your building is not functioning correctly, it is important that you contact the facilities manager or department safety contact to report the issue as soon as possible. For an autoclave in your laboratory, contact the manufacturer for information on service/repair. Principles of Microscopy Brightfield microscopy The microscope that is available to you for general use in this laboratory is a sophisticated optical instrument that can provide you with high-resolution images of a variety of specimens. Image quality is based largely on your ability to use the microscope properly. Below you will find some basic information that you have probably heard before, but information that is rarely presented in a thorough way. - Resolution The magnification of small things is a necessary facet of biological research, but the fine detail in cells and in subcellular components requires that any imaging system be capable of providing spatial information across small distances. Resolution is defined as the ability to distinguish two very small and closely-spaced objects as separate entities. Resolution is best when the distance separating the two tiny objects is small. Resolution is determined by certain physical parameters that include the wavelength of light, and the light-gathering power of the objective and condenser lenses. A simple mathematical equation defines the smallest distance (dmin) separating the two very small objects: dmin = 1.22 x wavelength / N.A. objective + N.A. condenser This is the theoretical resolving power of a light microscope. In practice, specimen quality usually limits dmin to something greater than its theoretical lower limit. N.A. (Numerical Aperture) is a mathematical calculation of the light-gathering capabilities of a lens. The N.A. of each objective lens is inscribed in the metal tube, and ranges from 0.25-1.4. The higher the N.A., the better the light-gathering properties of the lens, and the better the resolution. Higher N.A. values also mean shorter working distances (you have to get the lens closer to the object). N.A. values above 1.0 also indicate that the lens is used with some immersion fluid, such as immersion oil. From the equation above, you should be aware that the N.A. of the condenser is as important as the N.A. of the objective lens in determining resolution. It is for this reason that closure of the condenser diaphragm results in a loss of resolution. In practice, at full aperture and with good oil immersion lenses (N.A. 1.4 for both the condenser and the objective) it is possible to be able to resolve slightly better than 0.2 µm. From the equation above, it should also be clear that shorter wavelength light (bluer light) will provide you with better resolution (smaller dmin values). However, there are practical considerations in how short the wavelength can be. In the early 1950's, a UV microscope was designed, but required quartz objectives and a specialized imaging device. The quartz lenses provided slightly better resolution (dmin = 0.1 µm), but image quality suffered from an inability on the part of the manufacturers to correct for aberrations caused by the quartz. The human eye is best adapted for green light and our ability to see detail may be compromised somewhat with the use of blue or violet. Most manufacturers of microscopes correct their simplest lenses (achromats) for green light. - Magnification and Imaging Most microscopes in current use are known as compound microscopes, where a magnified image of an object is produced by the objective lens, and this image is magnified by a second lens system (the ocular or eyepiece) for viewing. Thus, final magnification of the microscope is dependent on the magnifying power of the objective times the magnifying power of the ocular. Objective magnification powers range from 4X to 100X. Lower magnification is impractical on a compound microscope stand because of spatial constraints with image correction and illumination. Higher magnification is impractical because of limitations in light gathering ability and shortness of working distances required for very strong lenses. Ocular magnification ranges are typically 8X-12X though 10X oculars are most common. As a result, a standard microscope will provide you with a final magnification range of ~40X up to ~1000X. Each objective lens consists of six or more pieces of glass that combine to produce a clear image of an object. The six or more lenses in the objective lens are needed to provide corrections that produce image clarity. The interaction of light with the glass in a lens produce aberrations that result in a loss in image quality because light waves will be bent, or refracted, differently in different portions of a lens, and different colors of light will be refracted to different extents by the glass. Spatial aberrations (e.g., spherical aberration) can be corrected by using lenses with different curvature on their surfaces, and chromatic (i.e., color) aberrations can be minimized by using multiple kinds of glass in combination. These corrections increase the cost of the lens to the extent that an apochromatic objective lens exhibiting full color correction and extremely high N.A. can cost several thousand dollars. This objective lens is about the size of your thumb. The objective lenses in most microscopes are achromats, and best suited for imaging with green light. Green filters narrow the bandwidth of the light, and make achromat objectives reasonably effective for most routine uses. The achromat lenses are not suitable for critical high-resolution imaging with white light, because red and blue light do not focus in the same plane as green light. Chromatic aberrations will degrade resolution in color images obtained with achromatic objectives. Color photomicrography aimed at the highest level of resolution and image clarity should be performed with totally corrected apochromatic objective lenses. Fluorite lenses, offer intermediate levels of correction, better than achromats but not as good as apochromats. Fluorite lenses are well suited for fluorescence microscopy because of their high transmittance of shorter wavelength light. Higher levels of correction make objective lenses more expensive; the price range for apochromatic objectives goes from about $3,000 to over $10,000. The oculars in most microscopes are designed to work optimally with the objective lenses from the same manufacturer. Each manufacturer makes some of the color and spatial corrections in the objective and the remainder of the corrections in the ocular. Mixing brands will usually result in a degraded image. In addition, when you look into a microscope, the magnified and corrected image you see through the oculars is actually a virtual image (as opposed to a real image). The ocular, designed to provide a corrected virtual image when viewed by eye, is not suitable for the generation of photographic or video images through the microscope. For photography or video microscopy it is necessary to use a projection lens that generates a corrected real image. Many of the newer microscopes provide total image corrections in the objective lens, thus obviating many of the concerns aboout matching glass components from the same manufacturer. Nevertheless, it is a good practice not to mix parts from one manufacturer with those of another, because unintended image degradation can result. - Illumination An essential factor in producing a good image with the light microscope is obtaining adequate levels of light in the specimen, or object plane. It is not only necessary to obtain bright light around the object, but for optimal imaging, the light should be uniform across the field of view. The best way to illuminate the specimen involves the use of yet another lens system, known as a condenser. The front element of the condenser is usually a large, flattened lens that sits directly beneath the specimen. Its placement on a movable rack provides you with the means to focus the light beam coming past the object and maximixe the intensity and control the uniformity of illumination. Two apertures in the illumination system allow you to regulate the diameter of the illumination beam by closing or opening iris diaphragms. One of these diaphragms, housed within the brightfield condenser and known as the condenser diaphragm, allows you to increase contrast, but at the cost of worsening resolution. The second of these diaphragms, known as the field aperture diaphragm, does not affect resolution as dramatically and is regularly adjusted for optimal illumination. Optimal illumination of a specimen with all microscopes currently manufactured is achieved by using a variation of Kohler Illumination, where (for those of you are technophiles) the filament of the light source is in focus at the rear focal plane of the objective lens. Operationally, it is easy to obtain optimal illumination for brightfield (or phase contrast) by first placing any specimen on the stage and focusing on the object. Next, turn the ring for the field aperture diaphragm (the lowest aperture on the microscope) so that its edges obscure the periphery of the field of view. Next, raise or lower the condenser until the edges of the field aperture diaphragm are clearly focused. Do not refocus the objective on the specimen while you are adjusting the condenser. It may be necessary to center the field aperture diaphragm, using the condenser centering screws. When the microscope is properly illuminated, both the object and the edges of the field aperture diaphragm should be in the same plane of focus and the field iris diaphragm should be centered in the field of view. Phase Contrast Microscopy The human eye can perceive changes in light amplitude (intensity). Unstained biological specimens, such as living cells, are essentially transparent to our eyes, but they interact with light in a fairly uniform way, by retarding (slowing) the passage of a light beam by approximately 1/4 of a wavelength ( ). By slowing a light beam this much relative to another light beam that had passed though the surrounding medium, the biological specimen alters the phase of the beams. Intensity (amplitude) is additive and light rays that are 1/2 out of phase are perceived as darkness. Zernicke realized that if he could retard the light passing through biological specimens without affecting the light passing through the surrounding medium, he could generate changes in amplitude within living cells. The phase contrast microscope was invented by Zernicke in the 1930's as a means to generate contrast in biological specimens, changing these invisible phase differences into visible amplitude differences. Zernicke employed an optical trick to separate the light beams interacting with the specimen from those that do not encounter the specimen. To separate the beams of light from each other, he placed a transparent ring (known as an annulus) in an opaque disk and inserted this disk into the optical path of the microscope, within the condenser. He placed a complementary ring inside the objective lens. Nearly all of the light that passes through the sample but misses the specimen then passes through the objective lens through this ring. Most of the light that passes through the specimen is scattered and some of it enters the objective lens in such a way that it will not pass through the objective lens ring, but will pass this plane in some other location. He designed the glass plate holding the ring so that all light missing the ring would encounter an additional 1/4 of retardation relative to the beams of light that had not interacted with the specimen, placing the light rays that had interacted with the specimen out of phase with rays that had not interacted with the specimen by 1/2 . He found that a reduction in intensity of the light that had not passed through the specimen would create a grey background and increase contrast even more, with some parts of the specimen darker and other parts of the specimen brighter than the background. The operation of any microscope in the phase contrast mode requires that you first set up proper brightfield illumination, with a centered field iris diaphragm whose edges are in focus in the specimen plane. Next, rotate the condenser turret cylinder until the number on the condenser turret matches the number engraved on the objective lens. Under this condition, the condenser annulus is matched to the phase ring present in the objective. Next, remove one of the oculars and insert the Bertrand focusing telescope into the ocular hole. This lens enables you to see the rear focal plane of the objective lens, the plane where the ring resides. You will see a bright circle of light (the condenser annulus) and a dark ring (present within the objective). The dark ring is stationary, but the bright annulus is not. You may need to align the annulus with the ring so that the two are superimposed. On the back side of your condenser, you will find two adjustment screws that permit this alignment to be performed. When the ring and the annulus are aligned, place the ocular back into the microscope. The difference between phase contrast and brightfield for the observation of living cells is significant. Fluorescence Microscopy In certain classes of atoms and molecules, electrons absorb light, become energized, and then rapidly lose this energy in the form of heat and light emission. If the electron keeps its spin, the electron is said to enter a singlet state, and the kind of light that is emitted as the electron returns to ground state is called fluorescence. If the electron changes its spin when excited, it enters the triplet state, and the kind of light that is emitted as the electron returns to ground state is known as phosphorescence. Phosphorescence is much longer-lived than fluorescence. Both fluorescence and phosphorescence emissions are of particular wavelengths for specific excited electrons. Both types of emission are dependent on specific wavelengths of excitation light, and for both types of emission, the energy of excitation is greater than the energy of emission. Described another way, of excitation light is shorter than of emission light. In biology, we can utilize fluorescence in localization reactions, to identify particular molecules in complex mixtures or in cells. Fluorescence has the advantage of providing a very high signal-to-noise ratio, which enables us to distinguish spatial distributions of rare molecules. To utilize fluorescence, we need to label the specimen (a cell, a tissue, or a gel) with a suitable molecule (a fluorochrome) whose distribution will become evident after illumination. The fluorescence microscope is ideally suited for the detection of particular fluorochromes in cells and tissues. The fluorescence microscope that is in wide use today follows the basic "incident-light" design of Ploem, who employed a novel arrangement of filters with a chromatic beam splitter (often wrongly called a dichroic filter both by biologists and microscope sales people). With the incident light fluorescence microscope, the object is illuminated with fluorescence excitation light through the objective lens. The object emits longer-l fluorescence in response to the shorterexcitation light. The objective lens then serves both for illumination and imaging. The chromatic beam splitter transmits or reflects light, depending on its color. For this application, shorter light is reflected and longer light is transmitted by the splitter. Ploem placed the chromatic splitter in the optical path between the objective lens and the ocular, at a 45° angle, so that it would reflect shorter light downward toward the objective. The longerfluorescence emission light would be transmitted through the chromatic beam splitter toward the ocular. The microscopes that you have utilized in this and other courses all operate in the same general fashion. Light beams pass through a condenser lens system and provide illumination of an object at many points simultaneously. For incident light fluorescence microscopy, the objective lens also acts as a condenser for the excitation light beam. In its interaction with the object, some of this light is absorbed, some of this light is scattered, some of this light is reflected, and some of this light is slowed or retarded (relative to a beam of light that does not pass through the object). A portion of the light that has interacted with the object then passes through the imaging lens system of the microscope where it provides us with visual or pictorial image information about the object. Like the process of illumination, the process of image generation operates in a parallel fashion, where large numbers of light beams contribute to the image simultaneously. Resolution is limited by the closeness of overlapping points of brightness or darkness. In a practical sense, the limit of resolution is 0.18-0.2 µm with the best available objective lenses and a good specimen. To observe cells with the fluorescence microscope, it is important to know the spectral characteristics of the fluorochrome that has been employed. In order to excite the fluorochrome properly and then observe its fluorescence emission, the appropriate filter packages must be present in the microscope. The fluorochrome may not fluoresce at all if the cells are illuminated with the inappropriate filter pack present in the optical path. Finally, for any kind of fluorescence localizations to be performed, it is essential to have the appropriate controls, to be sure that the cells do not exhibit excessive autofluorescence (that is, they do not glow in the absence of the fluorochrome), and that the fluorochrome is responsible for the localization pattern observed. In the laboratory, we have several microscopes equipped for incident light fluorescence microscopy. Confocal Scanning Optical Microscopy In the incident light fluorescence microscope, a light beam passes through a chromatic beam splitter and then the objective lens to illuminate a specimen. This light beam is used to excite electrons in fluorochrome molecules present in the object. As some of those excited electrons return to their ground state, the emission of light is detectable through the oculars of the microscope, or with a camera or video printer. The image is generated continuously, across the entire field of view. A primary problem with the fluorescence images generated in this way is that out-of-focus fluorescence appears as 'flare' in the object, and reduces the signal substantially. In addition, human eyes are not sufficiently sensitive photodetectors for the lowest levels of fluorescence, and most video-based imaging systems are only slightly better than your eyes. Under conditions where there is sufficient signal for you to easily observe fluorochrome distribution patterns, the excitation light can be of sufficient intensity to photooxidize (i.e., burn) your specimen. Much information can be lost with just a few seconds of exposure to the excitation lamp. The Confocal Scanning Optical Microscope, an expensive piece of instrumentation that illuminates the object with a small beam of light in a point-bypoint (i.e., serial) fashion, eliminates most of the photoxidation problems, permitting the observation of objects for extended periods at very high resolution with little loss of signal. The placement of a small aperture in the beam path generates a small depth of field, and effectively eliminates out of focus information in image formation. The confocal scanning optical microscope is designed to illuminate an object in a serial fashion, point by point, where a small beam of light (from a LASER) is scanned across the object rapidly in an X-Y raster pattern. The raster pattern can be created in several ways, but in one of the more popular instruments, it occurs as a consequence of the simultaneous rotation and vibration of a polygonal mirror. The vibration is caused by the activity of a servogalvanometer, while the rotation is caused by the activity of a small electric motor. Thus, a bright spot of light scans across an object from top to bottom, line by line. The image is also generated point-by-point. Image formation is translated into intensities at each spot in the X-Y raster by a photomultiplier tube. The intensity information is digitized and stored in a computer. A complex image processing software package permits visualization and manipulation of the images. Resolution is limited by spot size for the LASER and approaches 0.12-0.15 µm for an ideal specimen and with the best available objective lenses. The manufacturers of confocal scanning optical microscopes include a pinhole diaphragm at a very special place in the optical path, near to the site of the photomultiplier tube. This pinhole is situated in a plane where the light from the in-focus part of the image converges to a point. Light from object planes above or below that of the focused image do not converge at the spot in the optical path occupied by the pinhole. Because of this design, out of focus image information is darkened to the extent that it is not detectable. The consequence is that all out of focus information is removed from the image and the confocal image is basically an 'optical section' of what could be a relatively thick object. The 'thickness' of the optical section may approach the limit of resolution, but in practice, the resolution in the Z-direction is somewhat greater, approximately 0.4-0.8 µm. The value of optical sectioning is best realized with fluorescence microscopy, where out-of-focus information alters, distorts, or even degrades the image. Because the confocal images are stored in a computer, it is possible to stack them up and generate three-dimensional reconstructions. The image processing programs also enable us to rotate these images and observe three-dimensional aspects of cellular structure. It may be clear to you that the computer responsible for these image manipulations must be fast and powerful. The biggest problem is one of image storage, where single images can routinely occupy >1,000,000 bytes of space. In rather short periods of use, it is easy to accumulate sufficient numbers of images to fill the largest of hard disks. Two of the three the confocal scanning optical microscopes located on campus were manufactured by Carl Zeiss, located in Germany. The newest instrument (model 510) has three lasers and four photomultipliers and is designed so that we could illuminate with two or three colors of light in rapid succession and detect as many as three superimposed signals (essentially) simultaneously. The signals are separated from each other on the basis of color, using an acoustical optical tunable filter (AOTF). The optical microscope is an inverted stand. The most important operational difference between this microscope and the upright microscope in most laboratories is that with this instrument, the slide is placed in the stage holder upside-down. Like most modern research microscopes, this microscope is equipped for phase contrast, differential interference contrast and fluorescence microscopy and can be used with these imaging techniques for conventional imaging. However, it is equipped with a number of very highly corrected (read expensive) objective lenses attached to the turret, just below the stage. These lenses are necessary for high resolution confocal microscopy. The confocal part of this microscope is contained in a box that is attached to the inverted stand through an access port. As is the case with incident light fluorescence, the laser light passes through the objective lens to illuminate the specimen. An air suspension table is designed to eliminate vibrations present in the building. Deconvolution Microscopy and Image Reconstruction An alternative approach for eliminating flare from fluorescent image stacks is to perform intensive, iterative image analysis and processing, from objects that have been illuminated and photographed at multiple, adjacent focal planes. The images are obtained with a high-performance CCD camera, operating at very high magnification, using standard incident light fluorescence microscopy. The excitation source is a mercury arc lamp, and bandwidth for excitation and emission are controlled by filters placed in rotating filter wheels. The lamp is stabilized and the beam is randomized for uniform illumination of the specimen. Unlike confocal scanning instruments, the whole field of view is illuminated simultaneously with this microscope. It is possible to perform rapid sequential imaging (4 colors) from multiple fluorochromes with this microscope. At very high magnification, fluorescence from any spot in a cell acts as a point source. By knowing the image spread functions above and below the plane of focus, it is possible to determine points of origin for fluorescence, and spreading beams of light from that point source, above and below the plane of focus. An iterative algorithm, which is essentially a linear combination is performed by a computer on the adjacent pixels within a single image plane, and in successive image planes through the thickness of the object. Spreading light beams are subtracted from reconstructed image stack, and that light is added back to the source, thereby reducing noise and increasing signal, respectively. We have recently acquired a sophisticated DeltaVision microscope from Applied Precision, Inc., which is designed to acquire these images and then perform the computer-intensive operations. This kind of microscope is particularly well suited for generating three-dimensional fluorescence images from small, living cells. Polarization Light Microscopy - Birefringence - When light passes through an object, it interacts with some or all of the atoms and molecules present in that object. In these interactions, sometimes light of a particular (i.e., color) is absorbed by the atoms or molecules, while sometimes light is scattered. The interaction of light with a translucent object often results in a slight reduction in the velocity of the light beam. The extent of this reduction in velocity can be measured as the refractive index of the object. For certain kinds of objects, especially those with high order in particular axes of the object, such a crystalline or paracrystalline arrays, the interaction with light beams is vastly different, depending on the orientation of the object relative to the impinging light beam. As a result, the refractive indices are measurably different in different axes of the object. Such an object with multiple refractive indices is termed birefringent. Birefringence (multiple refractive indices) results from the alignment of atoms or molecules in particular planes of an object; these atoms or molecules interact strongly with light beams impinging on them from a particular direction, and to a far lesser extent with light beams impinging on them from a different direction. There are two kinds of birefringence, intrinsic birefringence, which results from atomic or molecular order in a crystalline or paracrystalline array (i.e., calcite crystals, membranes) and form birefringence, which results from supramolecular associations in paracrystalline arrays (i.e., microtubules in a spindle). - Polarized Light and Birefringent Retardation Any light beam shining in a particular direction vibrates in all directions around the axis of travel. Light beams whose vibration has been restricted to a single plane, or to a few planes is known as polarized light. Birefringence is directly observable as differences in intensity in different axes of crystalline or paracrystalline objects when they are viewed with polarized light. Since birefringence results from differences in the number of interactions between the light beam and atoms or molecules in the object in different directions, in practice, the object is rotated around the plane of vibration for the polarized light beam to maximize the intensity differences in the object (usually, the dominant object axis is at a 45o angle relative to the plane of polarization). The extent of the difference in refractive indices in different axes of the object is a measurable quantity known as birefringent retardation (BR). BR is measured (as a distance) by placing an object with known birefringent retardation into the light beam, and, by rotating the calibrated object around the optic axis, extinguishing the brightness in the sample. Using this compensation technique, BR has been shown to be directly related to the number of aligned microtubules in mitotic spindles in living cells. This principle and procedure can be of importance in studying microtubule dynamics, where mitotic spindles of developing sea urchins can be visualized in a totally noninvasive way. The stereo or stereoscopic or dissecting microscope is an optical microscope variant designed for low magnification observation of a sample using incident light illumination rather than transillumination. It uses two separate optical paths with two objectives and two eyepieces to provide slightly different viewing angles to the left and right eyes. In this way it produces a three-dimensional visualization of the sample being examined.[1] Stereomicroscopy overlaps macrophotography for recording and examining solid samples with complex surface topography, where a three-dimensional view is essential for analysing the detail. The stereo microscope is often used to study the surfaces of solid specimens or to carry out close work such as dissection, microsurgery, watch-making, circuit board manufacture or inspection, and fracture surfaces as in fractography and forensic engineering. They are thus widely used in large numbers in manufacturing industry, both for manufacture, inspection and quality control. It tends to make them of lower cost compared with conventional microscopes. The stereo microscope should not be confused with a compound microscope equipped with double eyepieces and a binoviewer. In such a microscope both eyes see the same image, but the binocular eyepieces provide greater viewing comfort. However, the image in such a microscope is no different from that obtained with a single monocular eyepiece. Differences to normal optical microscopes Unlike a compound light microscope, illumination in a stereo microscope most often uses reflected illumination rather than transmitted (diascopic) illumination, that is, light reflected from the surface of an object rather than light transmitted through an object. Use of reflected light from the object allows examination of specimens that would be too thick or otherwise opaque for compound microscopy. Some stereo microscopes are also capable of transmitted light illumination as well, typically by having a bulb or mirror beneath a transparent stage underneath the object, though unlike a compound microscope, transmitted illumination is not focused through a condenser in most systems. [2] Stereoscopes with specially-equipped illuminators can be used for dark field microscopy, using either reflected or transmitted light.[3] Great working distance and depth of field here are important qualities for this type of microscope. Both qualities are inversely correlated with resolution: the higher the resolution (i.e. the shorter the distance at which two adjacent points can be distinguished as separate), the smaller the depth of field and working distance. A stereo microscope has a useful magnification up to 100×, comparable to a 10× objective and 10× eyepiece in a normal compound microscope, and is often much lower. This is around one tenth the useful resolution of a normal compound optical microscope. The large working distance at low magnification is useful in examining large solid objects such as fracture surfaces, especially using fibre-optic illumination. Such samples can also be manipulated easily so as to determine the points of interest. There are severe limitations on sample size in scanning electron microscopy, as well as ease of manipulation in the specimen chamber. Magnification There are two major types of magnification systems in stereo microscopes. One is fixed magnification in which primary magnification is achieved by a paired set of objective lenses with a set degree of magnification. The other is zoom or pancratic magnification, which are capable of a continuously variable degree of magnification across a set range. Zoom systems can achieve further magnification through the use of auxiliary objectives that increase total magnification by a set factor. Also, total magnification in both fixed and zoom systems can be varied by changing eyepieces.[1] Intermediate between fixed magnification and zoom magnification systems is a system attributed to Galileo as the "Galilean optical system" ; here an arrangement of fixed-focus convex lenses is used to provide a fixed magnification, but with the crucial distinction that the same optical components in the same spacing will, if physically inverted, result in a different, though still fixed, magnification. This allows one set of lenses to provide two different magnifications ; two sets of lenses to provide four magnifications on one turret ; three sets of lenses provide six magnifications and will still fit into one turret. Practical experience shows that such Galilean optics systems are as useful as a considerably more expensive zoom system, with the advantage of knowing the magnification in use as a set value without having to read analogue scales. (In remote locations, the robustness of the systems is also a non-trivial advantage.) Illumination Small specimens necessarily require intense illumination, especially at high magnifications and this is usually provided by a fibre-optic light source. It utilizes halogen lamps which provide high light output for a given power input. They are small enough to be fitted easily near the microscope, although often need cooling to ameliorate high temperatures from the bulb. The fibre-optic stalk gives the operator a high degree of freedom in choosing appropriate lighting conditions for the sample. The stalk is encased in a sheath which is easy to move and manipulate to any desired position. It is normally unobtrusive when the lit end is near the specimen, so usually does not interfere with the image in the microscope. Examination of fracture surfaces frequently need oblique lighting so as to highlight surface features during fractography, and fibre-optic lights are ideal for this purpose. Several such light stalks can be used for the same specimen, so increasing the illumination yet further.