Excavation Permit

advertisement

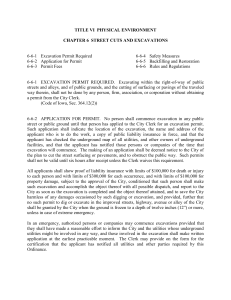

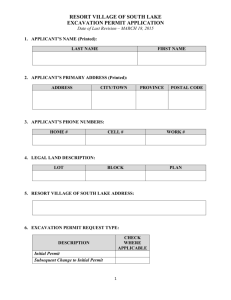

MURPHY OIL U.S.A., Inc. MERAUX REFINERY POLICIES AND PROCEDURES SSP-0006 Date Issued: Supersedes: Page 1 of 3 11-02-09 10-31-08 TITLE: Procedure for Excavation Permits PURPOSE: Due to the possibility of damaging buried piping, wiring and the potential injuries which may ensue, an excavation permit is required to perform machinery-assisted excavation and similar activities. Note: The excavation permit is required in addition to a safe work permit. RESPONSIBILITIES: Department Managers - Murphy Oil Management shall fully support the safe practices covered by this document. Any deviation shall follow SSP-0029 “Deviation From Standard Safety Procedures.” Operations Area Superintendent buried process or utility piping, underground in the area of the excavation permit if any hazardous Assess the possibility of tubing, etc. being located excavation. Rescind the conditions arise. Environmental Department – Assess the possibility of contaminated soil being located in the excavation area. Determine the storage and disposition requirements of spoils which will be accumulated during the excavation. Safety Department – When required, assess the excavation location for underground fire water piping, and the need for sloping/shoring. Rescind the excavation permit if any hazardous conditions arise. Project Engineer – Determine the location and dimensions of the excavation site. Obtain the MOUSA excavation permit from the intranet. Ensure proper communication between all parties relative to the excavation site and work scope. Electrical Engineer or Maintenance Electrical Foreman Assess the possibility of buried conduit, cable, duct banks, etc. being located underground in the area of the excavation. Rescind the excavation permit if any hazardous conditions MURPHY OIL U.S.A., Inc. MERAUX REFINERY POLICIES AND PROCEDURES SSP-0006 Date Issued: Supersedes: Page 2 of 3 11-02-09 10-31-08 arise. Area Maintenance Foreman - Assess the possibility of buried pipe, conduit, cable, tubing, culverts and any other obstruction which could be located in the excavation area. Rescind the excavation permit if any hazardous conditions arise. Excavation Foreman - Obtain the MOUSA excavation permit from the intranet. Fill out the “work description and extent” portion of the excavation permit. Inform all personnel signing the excavation permit of any changes in equipment, scope, etc. Ensure the work description and extent, and special precautions sections of the excavation permit are reviewed with all personnel working in his crew. Ensure that upon assignment, all equipment operators review and sign the excavation permit. Excavation Equipment Operator – Review the MOUSA excavation and safe work permit. Follow all precautions listed on the excavation and safe work permit. Sign the excavation permit to acknowledge that the permit has been reviewed and is understood. Notify excavation foreman if any unsafe conditions are observed. PROCEDURE: Upon starting a job task which will involve ground breaking with machinery, an excavation permit must be printed from the forms tab on the MOUSA intranet. Such ground breaking activities include, but are not limited to, any digging with a backhoe/trackhoe, motor grading, pile driving, mechanical trenching ("ditch witching"), concrete or asphalt breaking with pneumatic hammers, concrete saws or rams, soil boring, soil auguring, fence post installation, etc. The Electrical Engineer, Electrical Maintenance Foreman, and/or the Area Maintenance Foreman will be advised by the Project Engineer and/or Excavation Foreman of the extent of the intended excavation. Upon notification, the Electrical Engineer, Electrical Maintenance Foreman, Area Maintenance Foreman/Construction Coordinator, Excavation Foreman, and Project Manager will investigate the scope of the job by performing a field walk to assess the possibility of buried pipe, conduit, cable, tubing, culverts and any other obstruction which could be located in the excavation area. If MURPHY MERAUX REFINERY POLICIES AND PROCEDURES SSP-0006 OIL U.S.A., Inc. Date Issued: Supersedes: Page 3 of 3 11-02-09 10-31-08 necessary, he will consult with the Area Operations Superintendent, Safety Department and/or anyone else who can assist in assessing the hazards of and damage risk to underground obstructions located within the excavation area. If the Electrical Engineer, Electrical Maintenance Foreman, Area Maintenance Foreman/Construction Coordinator, Excavation Foreman, and Project Manager deem the intended activity safe, they will sign the Excavation Permit (see Form E-300). The permit will be prepared and list the date, location, excavating company's name, general description and extent of the work, special precautions to be taken and signed by the Electrical Engineer/Area Maintenance Foreman, the operations area superintendent, an environmental department representative, the project engineer, and the excavation foreman. The excavation foreman will keep the original and the Project Engineer/Manager will retain a copy until the job is completed. The permit shall be issued once and remain valid through the completion of the job or until the scope of the work changes. The excavation permit may be rescinded by the Electrical Engineer/Area Maintenance Foreman, Operations Area Superintendent or Safety Department. NOTE: Manual digging for exploratory purposes may be required by the Electrical Engineer, Maintenance Electrical Foreman, Area Maintenance Foreman, or Project Engineer to more safely evaluate the area prior to using powered excavation equipment. Issued by: Michael Shephard, CSP Safety and Security Superintendent Approved by: Doug Frueh Manager – Safety, Security & PSM Approved by: Lynn Bourgeois Refinery Manager MURPHY OIL U.S.A., Inc. MERAUX REFINERY POLICIES AND PROCEDURES SSP-0006 Date Issued: Supersedes: Attachment 11-02-09 10-31-08