Course Descriptor Template - Heriot

advertisement

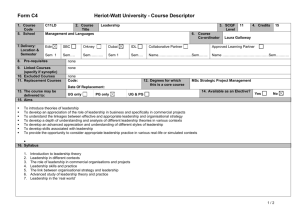

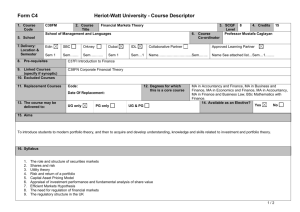

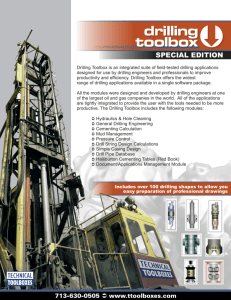

Form C4 Version 4.0 (2010/2011) Heriot-Watt University - Course Descriptor Template Course Code 1. Course Title G10DR 2. SCQF Level Drilling 5. Course Co-ordinator 4. School Engineering and Physical Sciences 6. Delivery: Location & Semester Edin SBC Orkney Dubai IDL Sem 2 Sem……. Sem……….. Sem…….. Sem…. Collaborative Partner Baku Higher Oil School, Azerbaijan Sem 2 10 3. Credits 150 4th Year Director of Studies Approved Learning Partner Name …………………………………Sem……….. 7. Pre-requisites 8. Linked Courses (specify if synoptic) 9. Excluded Courses 10. Replacement Courses Code: 11. Degrees for which this is a core course Date Of Replacement: 12. The course may be delivered to: UG only PG only UG & PG BEng Petroleum Engineering 13. Available as an Elective? Yes No 14. Aims The overall aim of this course is to: understand the concepts and techniques used in drilling engineering examine the design requirements of well planning and construction optimise the design of a drilling program 15. Syllabus Overview of Drilling Operations: To review the processes required to drill wells; to consider the different types of well - exploration, appraisal, development – and their role in the exploration and production of a reservoir; to discuss the resources required in terms of equipment and personnel. Rig Components: To review the functions of a drilling rig – types, locations, capacities, drilling systems. To examine the main systems – power, hoisting, circulation, cleaning. Drillstring: Review the function and design of a drillstring for specific operations; to examine the use of stabilisers and mud motors in achieving deviated drilling; to calculate and design the appropriate components to achieve a deviated well; the use of logging (MWD and LWD) in achieving designed trajectories; review of data capture and analysis for MWD and LWD; Drillbits: To review the characterisation and selection of drill bits for specific formation properties; to assess the longevity of drill bits with reference to industry standards; to compare efficiency of drill bits by reference to cost and specific energy relationships. Formation Pore Pressure and Fracture Gradient: Understanding the generation of pore pressure within sediments; classification of pore pressure relative to hydrostatic pressure; calculation of pore pressure gradient; review of earth stresses and rock mechanical properties of sediments; calculation of fracture gradient; use of pore and fracture gradients to determine suitable casing setting depths. 1/3 Form C4 Version 4.0 (2010/2011) Heriot-Watt University - Course Descriptor Template Well Control: Design and use of casing in production and injection wells; design of cementing – primary and secondary; design of mud system and appropriate mud weight for specific designs; review of BOP’s in drilling and their function in well control. Drilling Fluids: Review of types of fluids; design requirements of drilling mud – hole cleaning, bit cooling, formation stabilisation; chemical interaction of drilling fluids and sediments; remedial operations to counteract blowouts and kicks; design of bit hydraulics and calculation of fluid power requirements. 16. Learning Outcomes (HWU Core Skills: Employability and Professional Career Readiness) Subject Mastery Understanding, Knowledge and Cognitive Skills Scholarship, Enquiry and Research (Research-Informed Learning) On completion of the course, the student should be able to: understand and appreciate the mechanism of well drilling calculate the deviation required to reach a specific reservoir target and design the well path understand drillstring hydraulics and produce a suitable bottomhole assembly design for each hole section produce a casing design for a well understand and be able to calculate mud densities to overcome an unexpected well influx (kick) and to design a circulation method to return to safe operation design a cementing operation Personal Abilities Industrial, Commercial & Professional Practice Autonomy, Accountability & Working with Others Communication, Numeracy & ICT After completing this module, students will be able to: Appreciate the scale and complexity of the industry. Be aware of the social responsibility in protecting the environment and personnel in oil and gas operations. Understand the role of design codes. Understand the role of empiricism and approximation in design calculations. Develop appropriate skills in problem solving. Appreciate the practical application of chemical engineering fundamentals to equipment design. 17. Assessment Methods Method 18. Re-assessment Methods Duration of Exam Weighting (%) Synoptic courses? Method (if applicable) Examination Coursework 2 hours Duration of Exam (if applicable) 75% 25% None – qualifying course 19. Date and Version 2/3 Diet(s) Form C4 Date of Proposal Heriot-Watt University - Course Descriptor Template 13-8-2012 Date of Approval by School Committee Date of Implementation Version 4.0 (2010/2011) Version Number 3/3 1.1