Supplementary Material_Final

advertisement

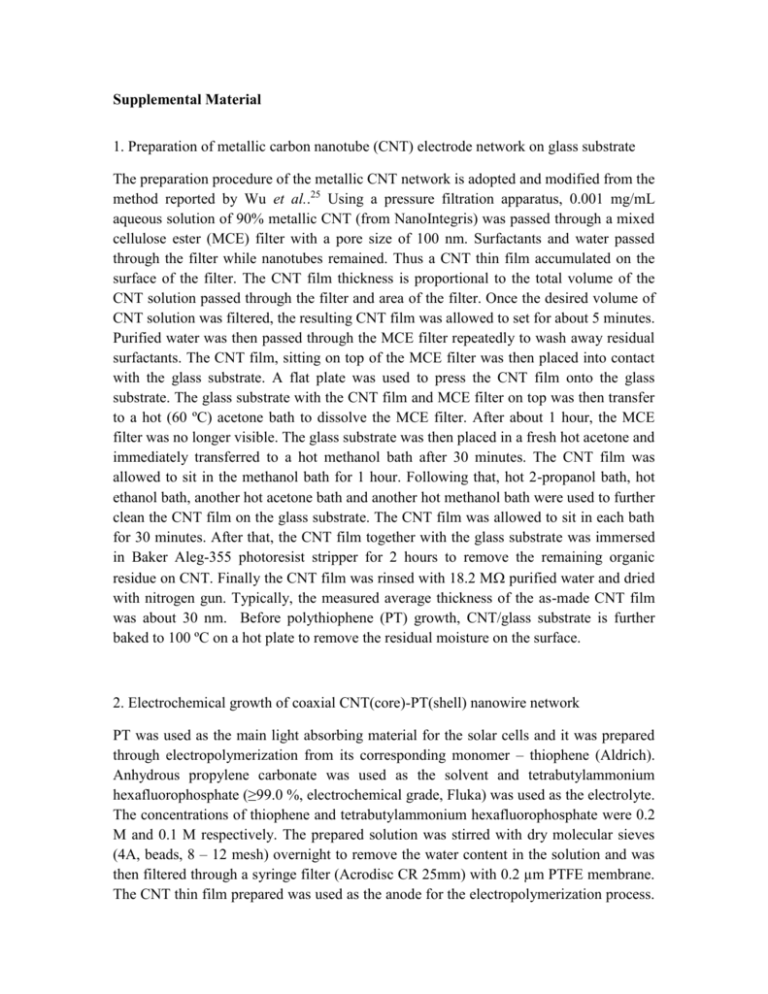

Supplemental Material 1. Preparation of metallic carbon nanotube (CNT) electrode network on glass substrate The preparation procedure of the metallic CNT network is adopted and modified from the method reported by Wu et al..25 Using a pressure filtration apparatus, 0.001 mg/mL aqueous solution of 90% metallic CNT (from NanoIntegris) was passed through a mixed cellulose ester (MCE) filter with a pore size of 100 nm. Surfactants and water passed through the filter while nanotubes remained. Thus a CNT thin film accumulated on the surface of the filter. The CNT film thickness is proportional to the total volume of the CNT solution passed through the filter and area of the filter. Once the desired volume of CNT solution was filtered, the resulting CNT film was allowed to set for about 5 minutes. Purified water was then passed through the MCE filter repeatedly to wash away residual surfactants. The CNT film, sitting on top of the MCE filter was then placed into contact with the glass substrate. A flat plate was used to press the CNT film onto the glass substrate. The glass substrate with the CNT film and MCE filter on top was then transfer to a hot (60 ºC) acetone bath to dissolve the MCE filter. After about 1 hour, the MCE filter was no longer visible. The glass substrate was then placed in a fresh hot acetone and immediately transferred to a hot methanol bath after 30 minutes. The CNT film was allowed to sit in the methanol bath for 1 hour. Following that, hot 2-propanol bath, hot ethanol bath, another hot acetone bath and another hot methanol bath were used to further clean the CNT film on the glass substrate. The CNT film was allowed to sit in each bath for 30 minutes. After that, the CNT film together with the glass substrate was immersed in Baker Aleg-355 photoresist stripper for 2 hours to remove the remaining organic residue on CNT. Finally the CNT film was rinsed with 18.2 M purified water and dried with nitrogen gun. Typically, the measured average thickness of the as-made CNT film was about 30 nm. Before polythiophene (PT) growth, CNT/glass substrate is further baked to 100 ºC on a hot plate to remove the residual moisture on the surface. 2. Electrochemical growth of coaxial CNT(core)-PT(shell) nanowire network PT was used as the main light absorbing material for the solar cells and it was prepared through electropolymerization from its corresponding monomer – thiophene (Aldrich). Anhydrous propylene carbonate was used as the solvent and tetrabutylammonium hexafluorophosphate (≥99.0 %, electrochemical grade, Fluka) was used as the electrolyte. The concentrations of thiophene and tetrabutylammonium hexafluorophosphate were 0.2 M and 0.1 M respectively. The prepared solution was stirred with dry molecular sieves (4A, beads, 8 – 12 mesh) overnight to remove the water content in the solution and was then filtered through a syringe filter (Acrodisc CR 25mm) with 0.2 µm PTFE membrane. The CNT thin film prepared was used as the anode for the electropolymerization process. PT was grown electrochemically at a nominal current density of 1 mA/cm2. The grown PT was then electrically dedoped. The resulting PT yielded strong luminescence under UV irradiation. 3. Phenyl-C60-butyric acid methyl ester (PCBM) coating and top electrode contact PCBM was used to infiltrate and cover the entire coaxial CNT-PT nanowire network. 12.5 mg/mL solution of PCBM in chlorobenzene was spin-casted at 1400 rpm. The sample was then baked at 80 ºC under constant flow of forming gas for 5 minutes to remove the remaining chlorobenzene solvent and allow PCBM to form percolated paths for electron transport. Finally, top electrode contact was deposited by electron-beam evaporation. The base pressure of the deposition chamber is less than 2x10-6 Torr. 2 nm titanium was deposited followed by 60 nm aluminum at a rate of ~ 0.1 nm/sec.