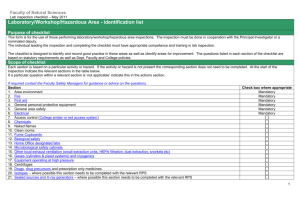

Hazard Checklist Core Safety - Facilities Management

advertisement

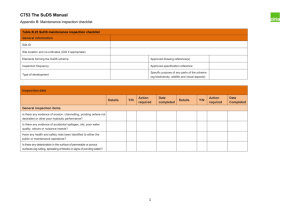

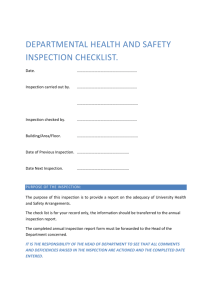

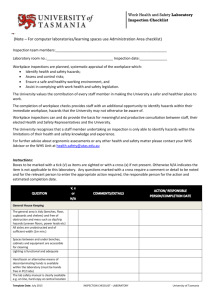

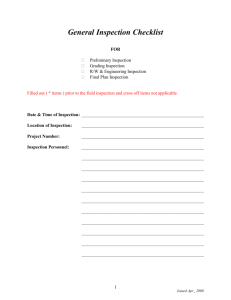

INSPECTION CHECKLIST Core Safety (for ALL FM Workspaces) Date: Campus Location of Inspection Inspection team Hazard checklists are only guides or prompt to identify hazards in all Facility Management work areas. The safety points are only to help look for typical safety hazards or safety system activities. Not every statement or prompt must be addressed in every inspection but any hazards or unsafe behaviour observed during the process should be recorded and dealt with in a timely way. The hazard inspection process uses the Core safety checklist and one or more of the other 4 specialised checklists – 1. Office or computer work 2. Maintenance workshops [non office areas] 3. Cleaning 4. Grounds The Core safety checklist is applicable to all workplaces. Inspection Procedure1. Any issues that aren’t relevant to the area should be marked as Not Applicable (NA) in the checkbox next to the safety criteria heading. 2. Inspections should be done by the supervisor for the area with the Health and Safety Rep (HSR) or another local staff member. 3. At the end of inspection, the supervisor and HSR reviews all non compliant or other safety issues identified. 4. Use the risk matrix; assess the risk levels of each non compliance or hazard identified. 5. Review safety systems currently in place and how effective they are? 6. Decide what new or modified risk control actions are required and their priority. 7. If unable to resolve the problem at local levels, the matter must be referred to the next level of management. 8. The inspection report must be signed off by the section manager, who will ensure responsibility for corrective action is allocated and given a reasonable period to remedy. Risk Matrix Likelihood Probable: The risk will occur in most circumstances. It has been known to occur in the last year in similar organisations Possible: The risk has been known to occur in the last 5 years in similar organisations. Improbable: The risk is rare and has not occurred in the last 20 years in similar organisations. Document1 Risk Response High Risk Do not start work. Inform Supervisor and do not proceed until the risk is eliminated or controlled through an Action Plan or a statement is provided and approved by Senior Management on why QUT should accept the risk. Medium Risk Inform Supervisor, consider additional or higher level controls (see Annex B), additional monitoring and response procedures and proceed only with Supervisor approval. Low Risk Proceed, maintain controls and manage through routine procedures. Consequence Major: Injury or health impact which results in permanent disability or death. Widespread environmental impact or localised impact likely to result in serious environmental harm and attract public attention. Impacts may be irreversible or only partially rehabilitated. Possible prosecution by regulatory authorities. Moderate: Injury or health impact which requires hospital treatment. Direct or indirect environmental impact beyond site. Impacts on areas of high environmental significance or areas of low significance with medium term or moderate impacts which are generally reversible. Typically reportable to regulatory authorities but unlikely to result in prosecution or an improvement/prohibition notice. Minor: Minor injury or health impact which requires first aid or medical treatment. 1 of 3 Environmental impact contained within site. Impacts on areas of low significance which are minor, short term and reversible. Impact often remediated within a week. INSPECTION CHECKLIST Core safety A. Fire Safety Details / Observations OK Not OK OK Not OK OK Not OK Action to be taken Vary checks on different fire equipment each inspection, 1. All fire system Inspections are current – [mandatory 6 monthly inspections] Fire extinguishers Hose reels Fire hydrants 2. All fire equipment has location marker clearly displayed. 3. Access to all fire equipment is clear extinguishers & hoses B. Emergency Evacuation 1. Evacuation maps/ diagrams & instructions are current & clearly displayed in work area. 2. Emergency exits & egress paths are clear of obstructions or stored items. 3. Egress travel paths & stairways are safe design and in good condition. 4. Emergency exit lights are clearly visible [ DO NOT press buttons to test] 5. Assembly areas are allocated, sign posted and understood by staff 6. Building warden identity is clearly displayed 7. At least one evacuation drill has occurred in previous yr. C. First Aid Facility 1. A first aid kit is available for each work area / group 2. First aid kit is checked regularly, restocked and cleaned. [ Note date of last check] 3. Kit has proper first aid signage or labels. 4. Kit contents contain only appropriate first aid equipment [no medications] 5. First aid personnel identified and contact numbers clearly displayed. 6. If no first aider – a person has been nominated to monitor the kit. 7. Emergency phone numbers are displayed clearly. 8. All first aid treatments and injuries are recorded on First aid Treatment form and original sent to HSAS annually. 9. A sharps disposal container is accessible. Document1 2 of 3 INSPECTION CHECKLIST Core safety D. Communication 1. 2. OK Not OK OK Not OK OK Not OK Action to be taken How does H & S information get to staff? A noticeboard or other display is provided for this work area. Basic H & S information is displayed including: QUT WH & S Policy Health and Safety Rep (HSR) First aid officer/s Building or area floor warden Emergency evacuation plan &/or procedures E. Electrical [ general] 1. Details / Observations Random checks on “specified” electrical equipment shows testing and tagging on required basis.[Elect Safety Reg] 2. 3. 4. 5. 6. Unsafe electrical equipment is not used, has been removed or tagged Out Of Service clearly visible. No piggy back plugs or double adaptors used. Clear access [1mt] available to all switchboards. Switchboards are locked, in good condition and clearly marked. Area is protected by Safety Switches [ RCD] . F. Material handling & storage 1. 2. 3. Materials are stacked correctly to prevent objects falling. Racks or bins used where possible. Easy access to stored items –floor is clear of trip items 4. Shelf capacity – not overloaded by quantity or weight– sufficient amount, strength, adequate fixing to wall, freestanding. 5. Commonly used or heavy items stored between mid thigh and shoulder height. Mechanical lifting aids available and in good condition– eg: trolleys – wheels, brakes; levers, lifters Waste bins are provided and emptied regularly Work or storage floor areas are clear of clutter and waste. 6. 7. 8. Correct stacking & storage prevent manual handling injuries and falling objects Document1 3 of 3