Experimental Modulus of Cantilevered Aluminum Beam Using

advertisement

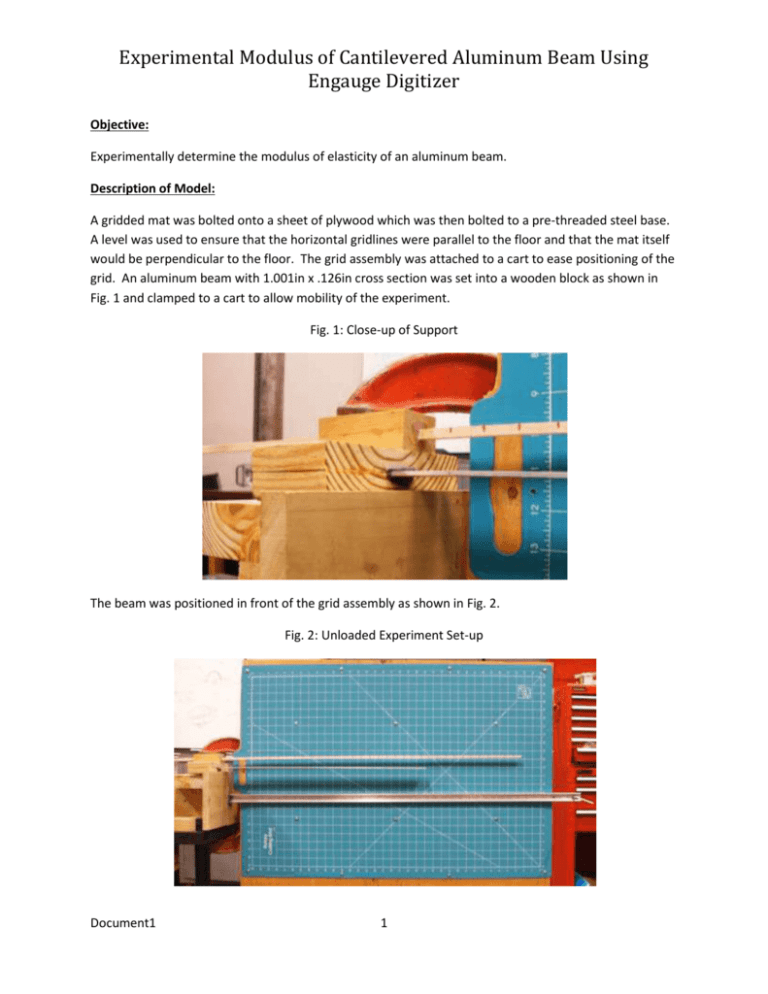

Experimental Modulus of Cantilevered Aluminum Beam Using Engauge Digitizer Objective: Experimentally determine the modulus of elasticity of an aluminum beam. Description of Model: A gridded mat was bolted onto a sheet of plywood which was then bolted to a pre-threaded steel base. A level was used to ensure that the horizontal gridlines were parallel to the floor and that the mat itself would be perpendicular to the floor. The grid assembly was attached to a cart to ease positioning of the grid. An aluminum beam with 1.001in x .126in cross section was set into a wooden block as shown in Fig. 1 and clamped to a cart to allow mobility of the experiment. Fig. 1: Close-up of Support The beam was positioned in front of the grid assembly as shown in Fig. 2. Fig. 2: Unloaded Experiment Set-up Document1 1 The load was applied as shown in Fig. 3. A bag of lead shot was hung by running wire through the bag and through the beam. A steel dowel pin through the wire allowed the beam to be easily loaded or unloaded. The load measured 205.6 grams or 0.45327 lbs on a triple beam balance. Fig. 3: Loading Close-up Below is the loaded beam in front of the grid assembly. Fig. 4: Loaded Experiment Set-up The unloaded and loaded images were imported into Engauge Digitizer to obtain the deflection at the load point. Results: Document1 2 The equation v PL3 was used with the previously measured parameters to calculate a modulus of 3EI 9.37*106 psi. The values used in the calculation are displayed below. With only 6.3% difference between this modulus and published values, this experiment has relatively good agreement between beam theory and measured values. P (lbs) L (in) b (in) h (in) I (in^4) 0.453270411 24.25 1.001 0.126 0.000166865 Unloaded Y Value -0.108978 Loaded Y Value -1.48666 v (in) 1.377682 9372553 Recommendations: If independent measurements were desired for comparison, modification would be required for supporting the measurement instruments. For example, one or more dial indicators could be used but the current model does not easily support indicators. If the beam were mounted in a proper frame, the frame could allow the instruments to be positioned as desired and the frame itself could be designed for portability. These concerns could be addressed by creating an experiment similar to the model shown in Fig. 5. Fig. 5: Inspiration for Improvement or Recreation of Model Relevant Files and Documents: Results and Reports, End of Summer\Cantilevered Aluminum Beam\Engauge Digitizer Files Results and Reports, End of Summer\Cantilevered Aluminum Beam\Photos Results and Reports, End of Summer\Cantilevered Aluminum Beam\Cantilevered Aluminum Beam.xlsx Document1 3 E (psi)