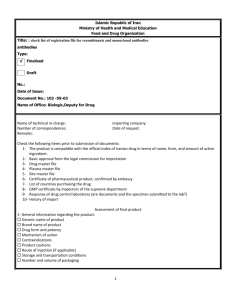

Islamic Republic of Iran Ministry of Health and Medical Education

advertisement

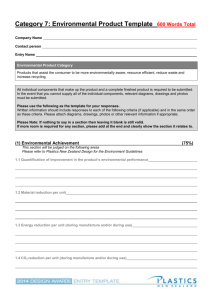

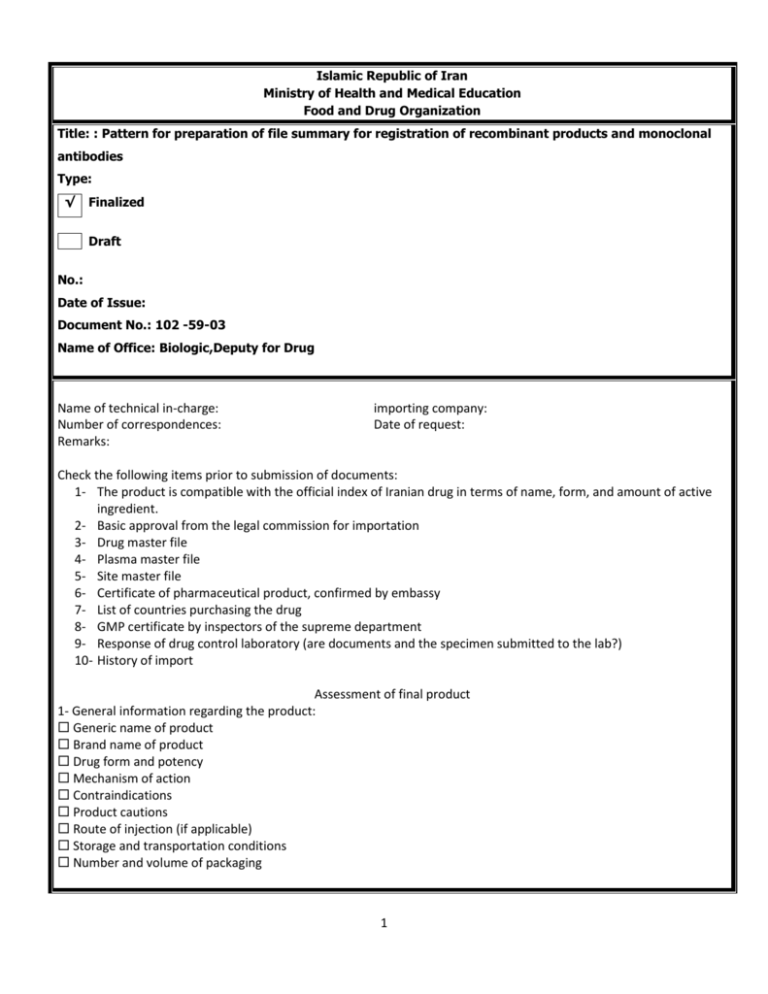

Islamic Republic of Iran Ministry of Health and Medical Education Food and Drug Organization Title: : Pattern for preparation of file summary for registration of recombinant products and monoclonal antibodies Type: √ Finalized Draft No.: Date of Issue: Document No.: 102 -59-03 Name of Office: Biologic,Deputy for Drug Name of technical in-charge: Number of correspondences: Remarks: importing company: Date of request: Check the following items prior to submission of documents: 1- The product is compatible with the official index of Iranian drug in terms of name, form, and amount of active ingredient. 2- Basic approval from the legal commission for importation 3- Drug master file 4- Plasma master file 5- Site master file 6- Certificate of pharmaceutical product, confirmed by embassy 7- List of countries purchasing the drug 8- GMP certificate by inspectors of the supreme department 9- Response of drug control laboratory (are documents and the specimen submitted to the lab?) 10- History of import Assessment of final product 1- General information regarding the product: Generic name of product Brand name of product Drug form and potency Mechanism of action Contraindications Product cautions Route of injection (if applicable) Storage and transportation conditions Number and volume of packaging 1 2- Information regarding manufacturer(s) Name and address of each of manufacturers and description of each one’s responsibilities List of other products which are manufactured in the same place as the product in question 3- Information regarding the manufacture process: Formulation with mention of amounts and function of each constituent for one drug unit Formulation amounts for one batch Manufacture process, including all stages of preparation, isolation and purification Controls during manufacture Proof of manufacture homogeneity Results of validation studies of key manufacture steps Description of equipment and method of maintenance and cleaning Methods of product transfer between manufacture steps or manufacture spaces Description of the sterilization operation 4- Information regarding auxiliary substances List of all auxiliary substances, manufacturing companies and their function in production All methods of control of auxiliary substances with mention of relevant reference Analysis sheet 5- Control of intermediate substances (these tests are different from those conducted during manufacture) All methods of control with mention of relevant reference Analysis sheet 6- Control of final product All methods of control of final product (identification tests, purity tests, etc) with mention of relevant reference Validation studies of control methods (for non-pharmacopeial tests) Analysis sheet 7- Information regarding stability Batch numbers tested, alongside manufacture date, site and size of batch Name and address of the laboratory where the test is conducted Test procedure - Expedited - Periodic Storage conditions of tested samples Packaging type of samples Duration of stability Test results (numerical results, chromatograms, gel photographs, peptide maps, etc) Final conclusion 8- Information regarding packaging Type and materials Name and address of manufacturing factory Results of tests of vessel compatibility with product, biologic tests, etc Results of permeability tests Results of vessel and cap integrity during stability period (for sterile products) Analysis sheet of packaging materials Sample label 2 Sample packaging vessel Sample brochure 9- Information regarding clinical and subclinical studies Study methods Formula used in studies Results Reference Assessment of Active Ingredient General information Name Molecular weight Aminoacid sequence Nucleic acid sequence Type of recombinant cell Storage conditions Expiry date Information regarding manufacturer(s) Name and address of each of manufacturers and description of each one’s responsibilities List of other products which are manufactured in the same place as the product in question Information regarding manufacture process Upstream Operation Host cell Origin of host cell, its phenotype and genotype Cell controls, including infection control etc Encoding gene Cell and origin of the gene Preparation method Map of limiting enzymes Vector Origin and function of each element (origin of replication, antibiotic-resistant genes, promoter, etc) Map of limiting enzymes which indicate the regions involved with vector production Important genetic markers in identification of producing cells Cloning and creation of recombinant cell lines Description of cloning process Physical status of the final structure inside the host cell (e.g. intrachromosomal or extrachromosomal) Method of selection of recombinant cell clones Mother cell bank Methods of preparation and analysis Date of preparation of cell bank, controls during manufacture and storage conditions Results related to determination of mother cell bank for identification and purification using appropriate phenotype markers 3 Results of limiting enzymes and results related to nucleotide sequencing of DNA, confirming the genetic sequence of expression structure Results indicating the stability of host cell and final gene structure during storage period Results indicating lack of infection of mother cell bank with infecting agents including, mycoplasma, bacteria, fungi, etc Working Cell Bank Method of preparing working cell bank, including procedure, culture medium and other elements Date of preparing working cell bank, relevant controls and storage conditions Quantity and amount of cell bank and number of passages from mother cell bank Final production cell Marking of final production cell in order to indicate homogeneity of biologic manufacture system during growth Results of phenotype or genotype markers of final production cell in order to confirm identification or purity Results of tests indicating lack of infection of final cell production with foreign agents Cell growth and harvest Composition of culture medium and sterilization method of the fermentation medium Process of prevention of infection with foreign agents for each step of fermentation Working conditions and controls during manufacture (appropriate range for parameters of manufacture and control, e.g. fermentation time, cell doubling time, purity of cell culture, pH, CO2, etc.) Controls during manufacture in different steps, including fermentation, harvest, etc. Validation studies related to key steps of cell culture, sterilization of culture medium, etc. Down-stream operation Quantity and amount of cell bank and number of passages from mother cell bank Purification methods Range of …………….. and endotoxin during operation (if applicable) Controls during manufacture in different steps of purification Validation studies related to purification operation (e.g. elimination of foreign agents, including chemicals, column contaminations, endotoxin, antibiotics, DNA, protein remaining from host cell and viruses, if applicable) Report of documents of batch production of active drug ingredient Standard reference: Submission of analysis sheet of standard international (WHO, NIBSC) or pharmacopeial (USP) standards Marking and determination of standard properties and submission of analysis sheet of standard in-house references Information regarding standard reference of stability Control of active drug ingredient All control methods of active drug ingredient (identification tests, purity etc.) with mention of relevant reference Physicochemical tests: appearance, pH Identification tests: western blot, densitometric isoelectric focusing, aminoacid analysis, sequence analysis of amine end, peptide mapping Identification and purity tests: SDS page (reduced and non-reduced), HPLC gel permeation chromatography, CHO immune-ligand assay, CHO DNA contaminant assay Potency: radioimmunoassay (RIA), mouse bioassay Other tests: A280 absorption and A280/A260 ratio, quantification of sialic acid using periodate resorcinol colorimetry, measuring neutral sugar, assessing viral, MMV and mycoplasma contaminations Validation studies of control methods (for non-pharmacopeial tests) Analysis sheet (for at least three consecutive batches) Stability of active drug ingredient Storage condition of active drug ingredient Method of conduct of stability tests for active drug ingredient and related results 4 System of vessel/cap Name and address of manufacturing company Results of compatibility tests, toxicity and biologic tests If the active drug ingredient is sterile, results and information of vessel/cap integrity for the suggested duration of stability 5