Synthesis of Pigments

advertisement

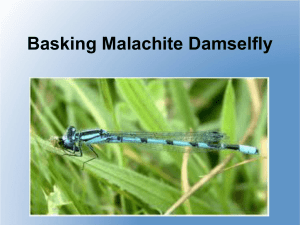

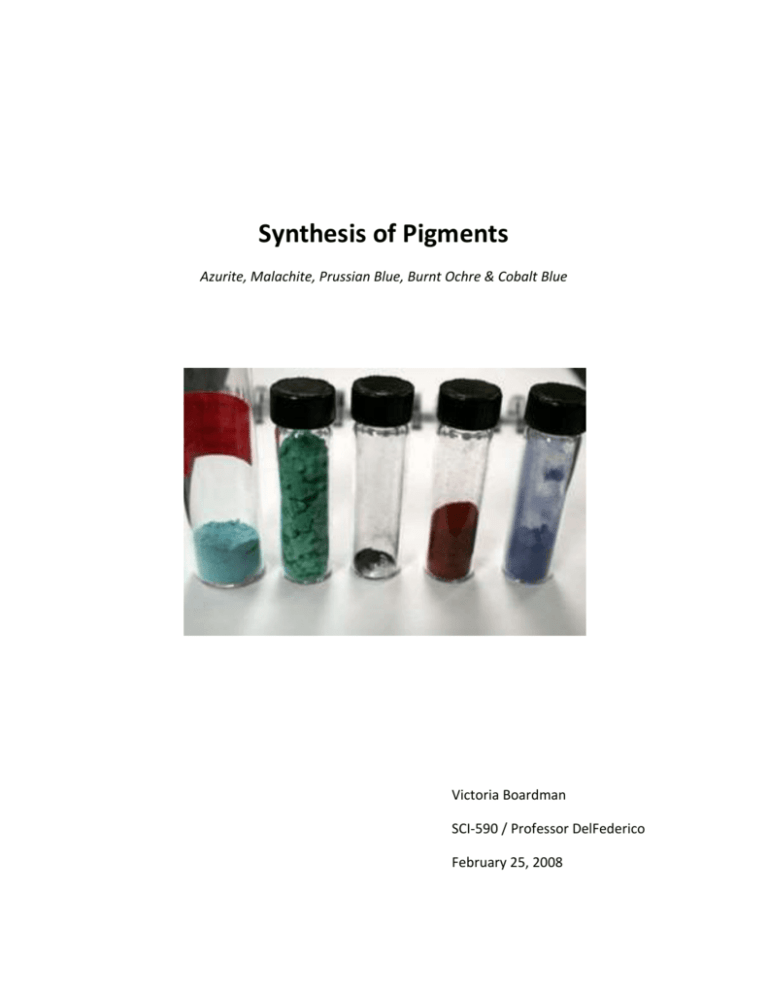

Synthesis of Pigments Azurite, Malachite, Prussian Blue, Burnt Ochre & Cobalt Blue Victoria Boardman SCI-590 / Professor DelFederico February 25, 2008 SYNTHESIS OF AZURITE & MALACHITE Procedure To synthesize azurite and malachite, we prepared two solutions: A – 12.5 g hydrated Copper (II) Sulfate (CuSO4 x H2O) dissolved in 50 mL deionized water B – 5.8 g sodium carbonate (Na2CO3) dissolved in 55 mL deionized water We slowly added solution B to solution A and observed the reaction. Half of the solution was filtered on week 1, and the second half was covered and stored for a week, then filtered on week 2. We washed the precipitates in the filtration apparatus with deionized water 3 or 4 times each. The reactions which occur are precipitation reactions forming both azurite and malachite: 3 Cu2+ + 2 CO32- + 2 OH- Cu3(CO3)2(OH)2 Azurite, also 2Cu(CO3)Cu(OH)2 2 Cu2+ + CO32- + 2 OH- Cu2(CO3)(OH)2 Malachite, also 2Cu(CO3) Azurite (left) and Malachite (right) after filtration Observations The initial solutions were transparent blue and colorless solutions. When combined, they produced a milky, gelatin-like solid at the bottom, copper hydroxide (Cu(OH)2). Bubbles of carbon dioxide (CO2) began rising to the surface, with a precipitate forming at the bottom. The color changed to an opaque duck egg blue color, with a thicker consistency. Azurite was filtered first, in week 1. While the final precipitate was not very different in color from the solution, it did become noticeably bluer when washed with deionized water. This washing removed soluble salts and extra hydroxide (OH-) ions. If left in solution, azurite would continue to react with the hydroxide ions to become malachite, so removing these ions is important to getting the best possible blue color. Synthesized Azurite The filtration of the second half of the solution in week 2 revealed it had already changed color to a light opaque green, and it had a more even consistency. This is consistent with the reaction proceeding further and forming the more stable malachite. Synthesized Malachite Conclusions The filtration of azurite revealed a light greenish blue colored precipitate. Compared with the mineral azurite, it is significantly lighter and paler, but when compared with commercially ground azurite, it is similar in hue, with a slightly yellower color. Washing helped turn this azurite bluer, and additional washings or repeated filtrations may have revealed a better color. The filtration of malachite was more successful, producing a color remarkably similar to commercially ground malachite. This is logical, since the reaction ran over a week and copper(II)carbonate is most stable in the form of malachite. AZURITE History of Use Malachite and azurite are found together in nature, often in the same stones. Azurite has been known to exist in nature since c. 25th century BCE, but it was not commonly used in western painting until the Middle Ages (c. 1300), when the recipe for Egyptian Blue was lost. It was used extensively as a warm sky blue through the Renaissance, and it was replaced by Prussian blue in the 18th century1. Azurite was an important pigment in Eastern wall paintings, employed in the cave temples at Dunhuang in China and used extensively through the Song and Ming dynasties2. Prior to the 19th century development of synthetic azurite, the pigment was ground from the stone. Coarser grindings resulted in more brilliant blues, and the more finely ground instances of azurite tend to be a paler, lighter blue3. Toxicity Azurite’s Material Safety Data Sheet (Number 410-10)4 lists it as RTECS Number: GL 69100005. It has the following acute toxicities6: Oral rabbit LD50: 159 mg/kg Oral rat LD50: 1350 mg/kg For humans, it may cause skin or eye irritation and may be harmful if ingested or exposed to mucous membranes and the upper respiratory tract through inhalation. Copper(II) Carbonate Hydroxide is not on any known or anticipated cancer lists and does not belong to any IARC7 category. Stability Azurite has good permanence in oil and tempera media8, though it is sensitive to heat, blackened by alkalis, and soluble even in weak acids9. It is unsuitable for use in fresco, as it turns to a grayish black through alkali exposure. It is not stable in an alkaline environment. It is otherwise fairly stable and does not seem especially susceptible to light fading in an oil or tempera binder. With time, humidity, and exposure to alkali lime mortar and alkaline salts, azurite commonly turns to malachite. 1 http://webexhibits.org/pigments/indiv/history/azurite.html Gettens, Rutherford J. & Stout, George L. Painting Materials: A Short Encyclopedia. Dover Publications, Inc, New York: 1966. “Azurite” p. 95-96. 3 Cennini, Cennino d’Andrea. The Craftsman’s Handbook “Il Libro dell’Arte”. Thompson, Jr, Daniel V., trans. Dover Publications, Inc: 1960. P. 35-36, Cennini warns of over-grinding: “When you have to lay it in, you must work up some of this blue with water, very moderately and lightly, because it is very scornful of the stone.” 4 http://www.naturalpigments.com/msds/msds_410-10.htm 5 Registry of Toxic Effects of Chemical Substances 6 Values here are given in LD50 format. From http://chemlabs.uoregon.edu/Safety/toxicity.html:“The LD50 (Lethal Dose, 50%) value is typically expressed in mg of material per kg of subject-body-weight, and indicates the quantity of material that, if administered to a population of subjects, will cause 50% of the subjects to perish.” 7 International Agency for Research on Cancer 8 http://webexhibits.org/pigments/indiv/technical/azurite.html 9 Gettens & Stout, p. 95. 2 Examples of Use Azurite has been used extensively throughout the history of art, notably in the basilica of St Francis in Assisi, where it was used a secco on a young girl’s dress and has changed to malachite. It can be seen in the Veronese painting Feast in the House of Levi, on view at the Accademia in Venice and in the Dunhuang Cave temples in China, along with countless medieval panel paintings and manuscripts. Chemical Formula & Explanation of Color The chemical formula of azurite is 2 CuCO3 · Cu(OH)2. It is known chemically as Basic copper(II)carbonate. It has a refractive index of alpha =1.73, beta =1.758, gamma =1.838. Copper is the metal element which gives azurite its color. Its ion is Cu2+, which combines with the carbonate (CO32-) and hydroxide (OH-) ions in a unique structural arrangement in space. This structure reflects light in the 400-487nm range, giving off a blue color. This means that it absorbs light in the orange range of 585-620nm, the energy required for an electron to move between the ground and excited energy levels, which we perceive as color. MALACHITE History of Use Malachite has appeared in Egyptian tomb paintings since the Fourth dynasty and was used as eye paint in predynastic times10. It was mainly used in European paintings in the 15th and 16th centuries11. It was used alongside azurite in Eastern wall painting and in European painting until about 1800 (most likely the verde azzurro identified by Cennini), when it was replaced by artificial green pigments12. Toxicity Malachite’s MSDS (Number 420-2013) lists it as RTECS Number: GL 6910000. It as the following acute toxicities: Oral rabbit LD50: 159 mg/kg Oral rat LD50: 1350 mg/kg As with azurite, for humans, it may cause skin or eye irritation and may be harmful if ingested or exposed to mucous membranes and the upper respiratory tract through inhalation. Copper(II) 10 Gettens & Stout, p. 128-9. http://webexhibits.org/pigments/indiv/history/malachite.html 12 Gettens & Stout, p. 128-9. 13 http://www.naturalpigments.com/msds/msds_420-20.htm 11 Carbonate Hydroxide is not on any known or anticipated cancer lists and does not belong to any IARC14 category. Stability Malachite is stable under ordinary conditions of use and storage. It is incompatible with Sodium hypobromite, acetylene, hydrazine, nitromethane, and strong acids. Its color is better preserved in tempera than oil binders15. While chemically similar to azurite, it does not have the same sensitivity in alkali environments. It is moderately lightfast. Examples of Use Malachite can be seen in the Dunhuang Cave temples and many eastern works such as Tang dynasty landscape paintings, alongside azurite. In its mineral form, it is used decoratively in jewelry and interior design, and as a pigment it can be seen in Michelangelo’s Sistine Ceiling. Chemical Formula & Explanation of Color The chemical formula of malachite is 2 CuCO3.Cu(OH)2 , and it is known as basic copper (II) carbonate. It has a refractive index of alpha =1.655, beta = 1.875, gamma = 1.909. Malachite differs from azurite in the amount and proportion of cupric hydroxide: Azurite: 2CuCO3.Cu(OH)2 Malachite: CuCO3.Cu(OH)2. The reaction in which azurite changes to malachite in the presence of water and alkali mortar is: 2CuCO3.Cu(OH)2 CuCO3.Cu(OH)2 + Cu2+ + CO32Here again, copper (Cu2+) is the metallic ion which gives malachite its color. Its structure is different from azurite, such that it reflects light in the 488-515nm range, which means it absorbs light around 620-780nm. SYNTHESIS OF PRUSSIAN BLUE Procedure To synthesize Prussian blue, we used two solutions: A – 25 mL of 0.5% solution of potassium ferricyanide, K3[Fe(CN)6] B – 15 mL of 2.0% solution of ferrous chloride, FeCl2 We slowly added solution B to solution A, then heated the solution to boiling on a hot plate. We boiled it for 10 minutes, then filtered it while hot. 14 15 International Agency for Research on Cancer Gettens & Stout, p. 128-9. The reaction that occurred was: Fe2+ + Fe(CN)63- Fe3[Fe(CN)6]2 Prussian blue Prussian blue after filtration Observations Initially, the ferrous chloride (solution A) was an orange-yellow color, and potassium ferricyanide (solution B) was a pale yellow-green. Our potassium ferricyanide had a slight brown tinge, which may suggest contamination. When mixed, the color changed immediately to a deep blue, with tiny particles of precipitate visible. As we heated the solution, it appeared slightly greener, and larger particles became visible. Once filtered, the precipitate was a deep, saturated blue, with a slight deep green tinge. We washed the cooled liquid once with room temperature deionized water. The liquid filtered out was a clear emerald green color. Synthesized Prussian Blue Conclusions We were concerned that the initial solutions were contaminated, but our precipitate did not reveal problematic interactions that impacted color. The blue that we got compared very favorably with commercially ground Prussian blue pigment. History of Use Prussian blue is the first modern, artificially manufactured color, created by Diesbach of Berlin around 1704 when experimenting with iron oxidation16. It has been available to artists since 1724 and remains a widely used and popular blue. Toxicity The MSDS for Prussian blue17 indicates that it has the following toxicities: IPR-RAT LD50 2100 mg kg-1 IPR-MUS LD50 2000 mg kg-1 ORL-MUS LD50 > 8000 mg kg-1 ORL-RAT LD50 > 8000 mg kg-1 It is considered not hazardous to handle and transport, but it is suggested to wear protective clothing and to avoid inhalation, ingestion, or excessive skin exposure. Stability Prussian blue is considered stable. It is incompatible with strong acids, strong oxidizing agents, and ammonia. It is light sensitive. It can acquire a metallic bronze cast when subject to outside weathering and can turn green in paint films from yellowing of the oil18. It is very sensitive to alkalis and cannot be used in true fresco. These images show a rapid degradation of Prussian blue when applied to fresco over approximately 30 minutes: 16 http://webexhibits.org/pigments/indiv/history/prussblue.html http://ptcl.chem.ox.ac.uk/MSDS/IR/iron_III_ferrocyanide.html 18 Gettens & Stout, p. 149-151 17 Prussian blue when initially applied to fresco (left) and degraded after 30 minutes (right). Examples of Use Prussian blue is commonly seen from the 18th century onward, notably in the works of Tiepolo and in Impressionist Claude Monet’s Bathing at La Grenouillère, 1869, among many others. Chemical Formula and Explanation of Color The chemical formula of Prussian blue is Fe[Fe3+Fe2+(CN)6]3, and it is known as Iron(III)hexacyanoferrate(II). The active metal in Prussian blue is iron, and the two ions present are Fe2+ and Fe3+. Essentially, the cyanide ions form a tetrahedron around the iron ions, and because of this structure, the irons are able to pass an electron back and forth. The irons in different states exchange this electron, which causes a constant interaction with light known as a charge transfer. This gives the compound a luminous color based on a band transition around 585-620nm, reflecting light at 440-490nm. SYNTHESIS OF BURNT OCHRE Procedure To synthesize burnt ochre, we put 1 gram of yellow ochre into a heat-safe Pyrex test tube. Under the hood, we heated it over the meker burner for about five minutes. The reaction that occurred was a dehydration reaction: Fe2O3 . nH20 (s) Fe2O3 (s) + nH2O (g) Heating yellow ochre to produce burnt ochre. Observations While in the flame, the pigment glowed a bright red, releasing water vapor. When removed, it was a chocolate brown color. Once cooled, it had turned to a brownish red, typical of Red ochre. Synthesized red ochre. It compared favorably with commercially-available red ochre, producing an almost identical color. Conclusions The heat of the flame was adequate to remove the water from within the yellow ochre’s structure. This is consistent with historical findings of yellow ochre turning to red in fires. It suggests that while yellow ochre is technically a stable pigment, it is susceptible to changes at high heat. History of Use Burnt or red ochre has been used since prehistory19, found in cave paintings and the earliest works of art, as it occurs naturally in the earth. It is used throughout the history of art, including as part of flesh tones in fresco. Toxicity Red ochre is considered nontoxic20, though its dust may act as an irritant to eyes, skin, and the respiratory system. Stability Red ochre has excellent permanence and is considered stable21. It is unaffected by light and is stable in alkali media; it is soluble only in hot concentrated acids22. Yellow ochre is not stable at high temperatures. Examples of Use Red ochre has been found synthesized in the Thermopolium at Villa Opplonti in Pompeii, where exposure to volcanic ash and fire turned yellow ochre red. It is also seen in cave paintings at Lascaux, countless frescoes, and was sometimes used to tint the ground layer of 19th century canvases. Chemical Formula and Explanation of Color The chemical formula of burnt ochre is Fe2O3, anhydrous iron(III)-oxide. Its refractive index is alpha =2.260 beta =2.393 gamma =2.398. Its metal is iron, in the ferric ion state (Fe3+). Yellow ochre is chemically similar to red ochre, but it has water molecules trapped within its structure. Exposure to heat causes the structure to release this water as a gas. The resulting anhydrous molecule absorbs light in the 490-570nm range and reflects light around 620-780nm. 19 http://webexhibits.org/pigments/indiv/history/redochre.html http://www.pcl.ox.ac.uk/MSDS/IR/iron_III_oxide.html 21 http://webexhibits.org/pigments/indiv/technical/redochre.html 22 Gettens & Stout, p. 122 20 SYNTHESIS OF COBALT BLUE Procedure To prepare cobalt blue, we mixed 1 gram of cobalt (II) chloride hexahydrate (CoCl2 . 6H2O) with 5 grams aluminum oxide (Al2O3). We ground these two solids together into a homogeneous mix using a mortar and pestle. This mixture was transferred to a heat-safe Pyrex test tube and heated over a meker burner under a vent hood for 5 minutes. The reaction which occurs is: CoCl2 . 6H2O + Al2O3 CoO.Al2O3(s) + 2HCl (g) + 5H2O(g) The cobalt (II) chloride hexahydrate reacts with the aluminum oxide to form cobalt (II)oxide-aluminum oxide, releasing hydrochloric acid and water as gases. Observations The initial color of aluminum oxide was a bright white, and the cobalt (II) chloride hexahydrate was a bluish purple. When combined, they were a light lavender color: While heating, the mixture bubbled vigorously and appeared to “melt” as it released water and hydrochloric acid as gases. It intensified to a bright blue color. When turned out into a dish, it was revealed that portions of our cobalt blue had not thoroughly heated and were therefore a lighter, grayish blue with a more granular texture. Synthesized cobalt blue Conclusions It is likely that the mixture was not heated long enough for the innermost portions to react. Stirring or agitating the tube may have helped ensure a more consistent reaction. Synthesized cobalt blue. The portions which did react fully compared favorably with commercially-available cobalt blue, though the overall mixture was lighter and grayer than anticipated due to these impurities. History of Use The first use of cobalt in art was in the form of smalt, a pigment made from ground cobalt blue glass. Chemists Gahn and Wenzel isolated cobalt aluminate in 1777. Manufacture of the cobalt blue pigment began in France in 1807, and it continues to be used today. Toxicity Cobalt has the following toxicities for ingestion23: CAS No. 1308-06-1: Oral, rat: LD50 = >5 gm/kg CAS No. 1307-96-6: Oral, rat: LD50 = 202 mg/kg Oral, rat: LD50 = 202 mg/kg The inhaled, eye, and skin toxicology data is not conclusively available at this time, but precautions should be taken when handling the pigment in particle form. Stability Cobalt blue is considered stable under ordinary conditions, with excellent permanence. It is stable in the presence of alkali medium and can be used in fresco and tinting concrete. It is insoluble in strong acids, unaffected by sunlight, and can be used for all painting techniques, as well as ceramic glazes24. Examples of Use Cobalt blue is found in many Impressionist paintings, including Renoir’s Les Parapluies. It is famously used in Maxfield Parrish’s illustrations such as The Dinky Bird, from Poems of Childhood by Eugene Field, 1904. Chemical Formula and Explanation of Color The chemical formula of cobalt blue is CoO · Al2O3 and it is known chemically as Cobalt(II)oxidealuminum oxide. The metal ions present are cobalt(II), Co2+ and aluminum, Al3+. It is the cobalt ion which is primarily responsible for the color, with the aluminum oxide acting as a base. Cobalt blue absorbs light in the range of 585-620nm, and it reflects light around 440-490nm. 23 24 From a related MSDS of Smalt - http://www.naturalpigments.com/msds/msds_417-13.htm Gettens & Stout, p. 108-9.