Tentamen spm4351 - schriftelijk deel

advertisement

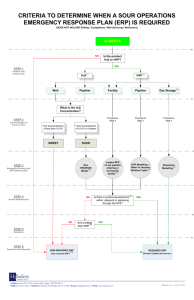

Tentamen spm4352 June 27, 2011, 9.00 – 12.00 This exam consists of 4 questions, each are worth 25 points. It is not allowed to consult books, or notes during the exam. Make assumptions and clarify them if you need to. Good luck! 1. Seed Oil to Biodiesel I [25 pt] See Figure on separate page. (from: http://iche.zju.edu.cn) Fresh streams of seed oil (stream 5) and methanol (stream 1) mix in the mixers (BA101, BA102) with fresh liquid propane (stream 4) and the recycled stream (stream 23, 27, 29) of methanol and propane. Then, the mixture (stream 8) is pumped to 12.8MPa and heated to 255℃ by system heat integration and middle pressure steam (5.1MPa, 265℃). Then, the mixture (stream 11) reaches the supercritical state and is fed into the reactor. The reaction is carried out in a tubular reactor (CA101).Heat conducting oil flows in the shell side to keep the reaction temperature at 300℃ and the reaction lasts for 5 minutes so that the conversion rate comes to almost 100%. The exit stream (stream 12) flows into a flash evaporator (BA103) after cooling. The gas (stream 21) recycles while the liquid stream (stream 15) flows into a distillation column (KA101). The light components come out from the top (stream 24), recycling; the bottom stream (stream 16), flows into the settler unit (BA105) after cooling. Finally, biodiesel is obtained as the light phase (stream 19) while the by-product glycerol is obtained as the heavy phase (stream 20). a) Follow Douglas’ hierarchy and re-engineer this process. [5] b) The description indicates that the reaction takes place in a tubular reaction. Sketch a diagram of the production of biodiesel as a function of the length of the pipe. Quantify where possible and state assumptions. [4] c) Plant operators notice that the total conversion of the seed oil in the reactor slowly reduces over a couple of days. Give two possible causes of this phenomenon using reactor and reaction characteristics or equations. [4] d) Would it be possible to execute this reaction in a CSTR? Explain your answer. [4] e) Conduct a brief HAZOP study on the reactor. Focus on temperature control of the reactor.[4] f) Assume that the biodiesel market collapses after a couple of years of operation. Indicate to what extent this plant / process can be reduced in capacity (what is your estimate of its turndown ratio?) while maintaining the specifications of the output in terms of purity / quality. Where would the first bottlenecks occur? [4] Please turn over 1/6 2. Seed Oil to Biodiesel II [25 pt] Consider the same process as in question 1 (see flowsheet and the pinch diagram on the reverse side of the separate page). a) The process contains two separation units. Which ones? And what are their main functions respectively? Describe one other way of achieving this function for each unit. [5] b) Assume that the design team wants to reduce the operating cost of this plant. What measures could they take on the distillation column in order to reduce operating cost? Explain your answer. [5] c) The distillation column’s temperature range is 48 – 228 oC (see flowsheet). What is your estimation of the boiling temperature of biodiesel at the column’s pressure (0.5 bar)? Explain your answer. [3] d) There is a composite curve diagram of the biodiesel process on the separate page. One can influence boiling temperatures by changing the pressure (higher pressure, higher boiling temperature). Study the diagram and discuss from a heat integration point of view whether or not it is useful to change the pressure in the distillation column. Indicate and explain how the shape(s) of the curve(s) would change and what the external heating and cooling requirements would become by sketching it on your answer sheet. No points are subtracted for ‘bad’ drawings, as long as it is clear what has changed compared to the original one (use colors / arrows / labels / encircling). Alternatively, you may hand in the separate sheet of this exam with your sketches and changes, including explanation and labels. In that case: do not forget to write your name and study number on the sheet). [6] e) Estimate / read the surplus of heat of this plant: indicate amount and temperature level. Discuss whether and how and under what conditions this heat can used for local city heating. Besides other relevant issues, include an economic analysis using life cycle costing concepts from the theory. [6] 2/6 Process Flow Diagram for Question 1 3/6 Temperature-Enthalpy diagram of biodiesel production. Horizontal axis: the illegible numbers read: 0.0 5.0 10.0 15.0 20.0 25.0 30.0 MW Vertical axis (bottom to top): 0.0 50.0 100.0 150.0 200.0 250.0 300.0 350 (oC). 4/6 3. Stranded gas, sour gas and electric power [40 pt] Around the world, many gas fields are to be characterized as “stranded” gas. A portion of these gas fields contains so-called “sour” gas – the natural gas is contaminated with hydrogen sulfide, H2S, and often also with carbon dioxide, CO2. Many sour gas fields of substantial size (>10 billion Nm3) lie scattered in the uninhabited, remote area's of Northern Canada. Apart from the standard technology – gas treatment in a continuous absorber/stripper combination using amines - it is also possible to physically absorb these contaminants in a molecular-sieve. Subsequently, the H2S,is converted to sulfur, a solid. If the quantities of H2S are very small, absorption in activated carbon may be considered. A clever SEPAM graduate has suggested that combustion of sour gas in a suitable (sour) gas fired power plant also would be a possibility. This plant then could be equipped with the flue gas cleaning facilities used normally with coal-fired power plants – as coal typically contains 0.1-2% wt. of sulfur. a) When is a gas field to be considered a “stranded” gas field? [5] Assume you are to advise Canadian Energy on the development of their newly discovered, relatively small sour gas field in Northern Canada (5 vol.% H2S, 80 vol.% methane, 3 vol.% ethane and 12 vol.% water). The pressure at the well-head is 250 bar, while the amount of gas is estimated at 18 billion Nm3, or about a third of the annual gas consumption of the Netherlands. The Canadian government regulations prescribe that any sour gas field must be depleted as fast as possible to minimize the safety risk of leakage of and exposure to H2S. b) What determines the production rate for which the system is to be developed? [5] c) What is(are) the main function(s) of the system to be developed? Briefly underpin your answer.[5] d) Identify at least three design objectives and three constraints for this system. Explain. [5] The field is located some 50 km from the nearest high pressure (80 bar) main transport pipeline that is connected to the North-American gas grid; along this gas transport pipeline also runs a 380 kV highvoltage electric power line. The infrastructure corridor is completed by a road that is suitable for the largest trucks and trailers. Below scheme (see other side) is taken from the spm4352 reader part II, where it is labeled a “Natural Gas System Superstructure”. It however, focuses on Midstream and Downstream, while sour gas processing typically takes place Upstream. e) Adapt and extend below superstructure to arrive at a superstructure that helps to explore options for the conceptual design for the system required to develop the Canadian sour gas field. Use your knowledge of gas systems and technology to exclude design options that are only suitable for large gas fields from your superstructure. Draw your diagram and explain it in text! [5] f) Let's focus on the contaminant removal system. Assume that optimal development of the field requires drilling 30 production wells, and that water and H2S are to removed immediately at the wellhead. Elect and design the water removal and sour gas treatment system. Draw and explain a principle system diagram and underpin by applying steps from the Douglas hierarchy where relevant. [5] g) Selecting a system design where electricity is the main product may require substantial investment in new high-voltage lines, not only to the feed-in point at 50 km, but also downstream in the existing network. Similarly, going for gas as the main product may require the gas pipeline grid downstream of the feed-in point to extended. Explain what options exist for expansion of the capacity of existing downstream pipeline segments. [5] 5/6 h) Go back to the superstructure that you developed. Describe the conceptual system design that you would advise to Canadian Energy. Use suitable design criteria to explain briefly why you advise this particular system design. [5] 6/6